Electric pulse auxiliary spinning forming machine tool

A technology of spinning forming and electric pulse, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of the temperature rise of the rotary wheel bearing, the inability to fully utilize the material, and the increase of contact resistance, so as to reduce energy loss, The effect of avoiding the reduction of the current utilization rate and improving the spinning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

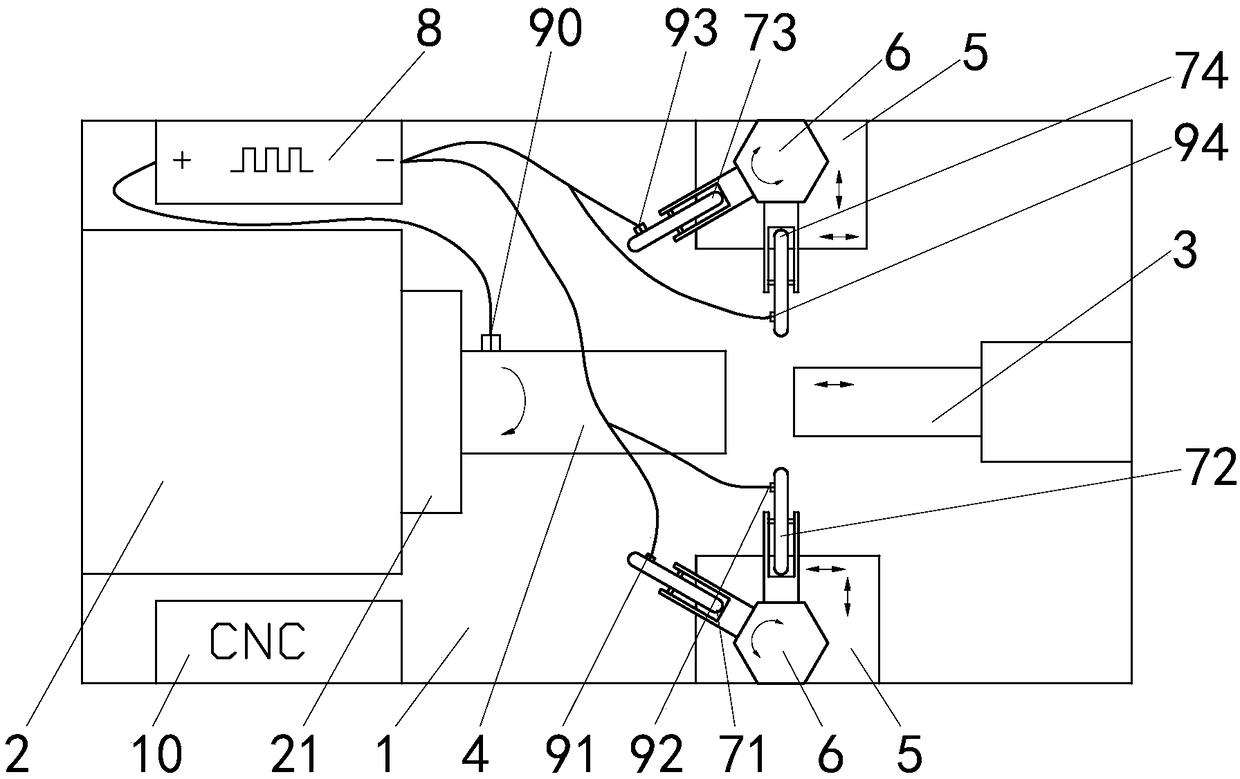

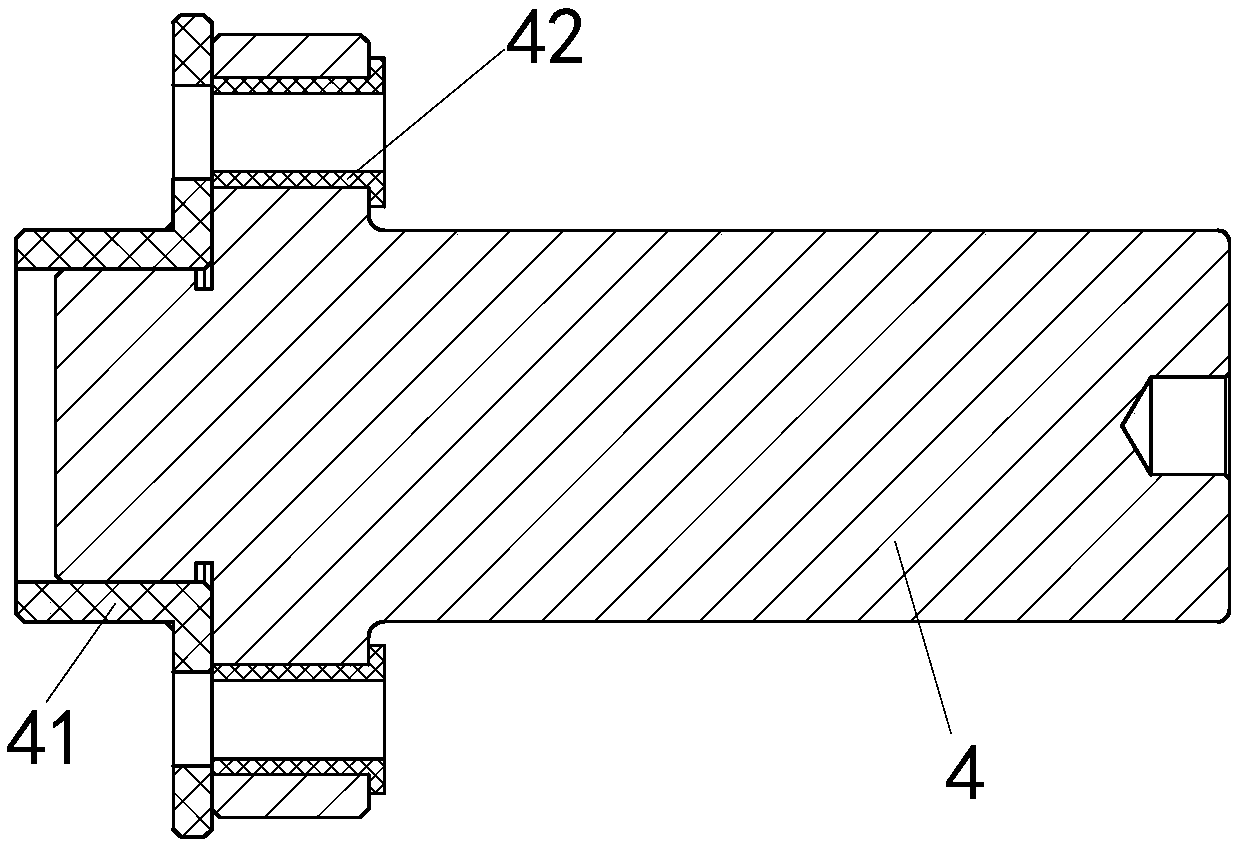

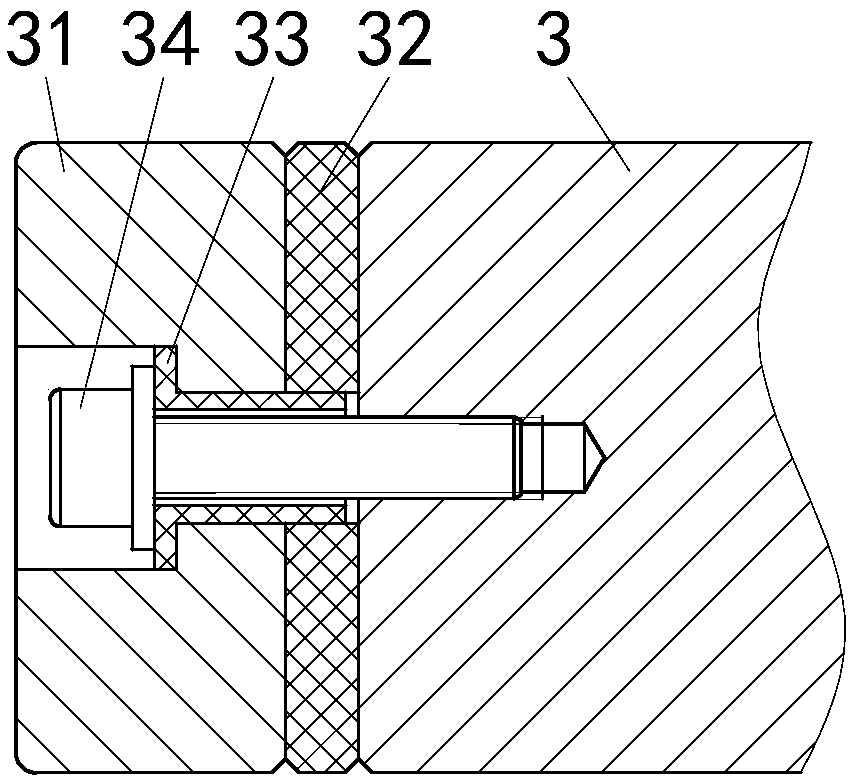

[0020] refer to figure 1 and Figure 5 , the present invention is an electric pulse assisted spinning forming machine tool, which includes a machine tool body 1, a high-energy pulse power supply 8 and a control unit 10, and the two ends of the machine tool body 1 are respectively fixed with a bedside box 2 and a tail top 3, and the bedside box Mandrel 4 is installed on the main shaft 21 of 2, and mandrel 4 rotates together with main shaft 21, and the center line of main shaft 21, mandrel 4 and tail crown 3 coincides, and the both sides of mandrel 4 and tail mandrel 3 are respectively provided with a movable On the mobile platform 5 that moves on the machine tool body 1, rotatable wheel seats 6 are installed on the two mobile platforms 5, and each wheel seat 6 is equipped with a wheel 7. The positive pole of the high-energy pulse power supply 8 passes through the brush 9 is connected to the mandrel 4, the negative electrode is connected to each rotary wheel 7 through the brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com