Lithium sulfide preparation method capable of realizing continuous production

A technology of lithium sulfide and lithium salt, which is applied in the direction of alkali metal sulfide/polysulfide, structural parts, electrical components, etc., can solve problems such as authenticity to be verified, and achieve the effect of promoting kinetics, reducing production costs, and shortening the process route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

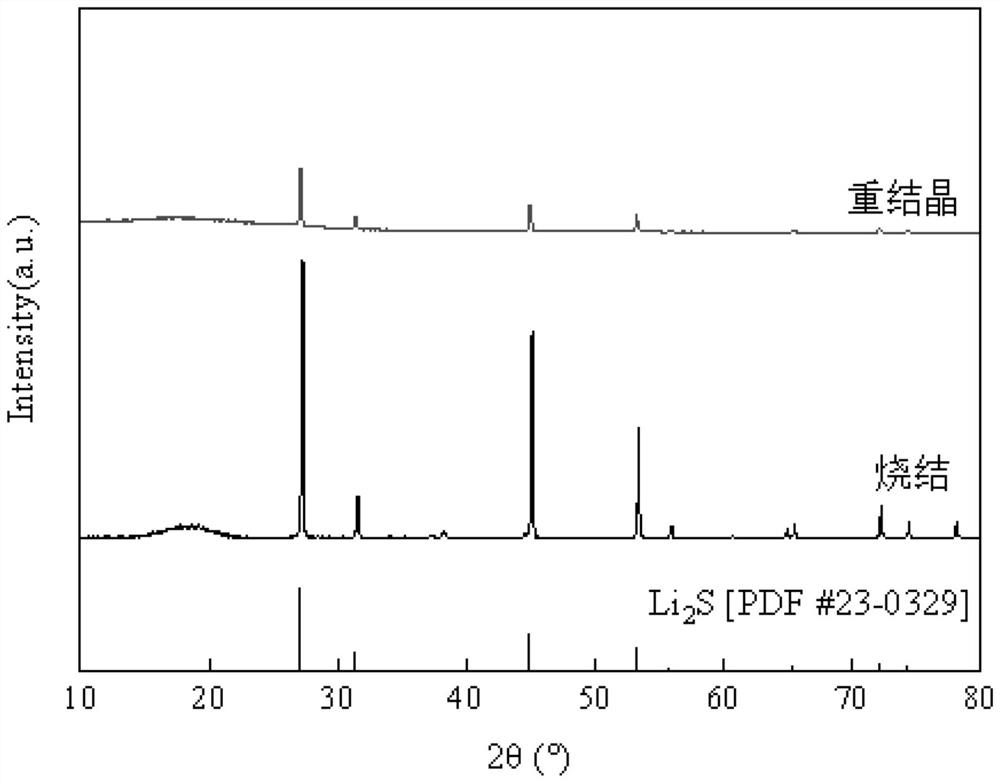

[0028] A kind of preparation method of the lithium sulfide that can realize continuous production that the present invention develops, main steps are as follows:

[0029] (1) Mix sulfur-containing lithium salt, organic carbon source and carbon material in proportion, disperse in organic solvent and wet mix;

[0030] (2) Press filter the resulting material and press it into a block in a mold, put the pressed material into a crucible, and use a tube furnace to sinter at a high temperature under the protection of fluid nitrogen, wherein sulfur powder is placed in the low temperature area, and sulfur powder is placed in the high temperature area. place materials;

[0031] (3) After the sintered material is crushed, it is dissolved in an alcohol solvent, and the solvent is removed in a vacuum oven to obtain lithium sulfide.

[0032] Step (1) is a material mixing process, mixing sulfur-containing lithium salt, organic carbon source and carbon material in proportion, and dispersing ...

Embodiment 1

[0043] Take 40g of lithium sulfate monohydrate, 5g of polyvinylpyrrolidone, and 5g of conductive carbon black and disperse in isopropanol, and use a high-speed mixer to mix at 1400rpm for 15min;

[0044] After the suspension is filtered, the filtrate is recovered, the filter cake is pressed into a square block in a mold and put into a crucible, the crucible is placed in the right temperature zone of the tube furnace, and the crucible containing a small amount of sulfur powder is placed in the left temperature zone;

[0045] Nitrogen gas is introduced from the left end of the tube furnace until the oxygen content in the tube furnace is less than 30ppm, the nitrogen flow rate is 100mL / min, the high temperature zone starts to heat up, and the nitrogen flow rate remains unchanged from the beginning of the temperature rise to the tube furnace cooling down to room temperature;

[0046] Heat the temperature in the high temperature zone to 250°C for 6 hours;

[0047] Heat the temperat...

Embodiment 2

[0055] Take 70g of lithium sulfate monohydrate, 15g of polydopamine, and 4g of conductive carbon black and disperse them in ethanol, and use a ball mill to mix the materials at 400rpm for 30min;

[0056] After the suspension is filtered, the filtrate is recovered, the filter cake is pressed into a square block in a mold and put into a crucible, the crucible is placed in the right temperature zone of the tube furnace, and the crucible containing a small amount of sulfur powder is placed in the left temperature zone;

[0057] Nitrogen gas is introduced from the left end of the tube furnace until the oxygen content in the tube furnace is less than 30ppm, the nitrogen flow rate is 300mL / min, the high temperature zone starts to heat up, and the nitrogen flow rate remains unchanged from the beginning of the temperature rise to the tube furnace cooling down to room temperature;

[0058] Heat the temperature in the high temperature zone to 280°C for 7 hours;

[0059] Heat the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com