A kind of high specific gravity tungsten alloy material and preparation method thereof

A tungsten alloy and high specific gravity technology, which is applied in the field of high specific gravity tungsten alloy materials and their preparation, can solve the problems of alloy materials such as limited deformation, tensile strength and elongation, coarse microstructure, and reduced plasticity, so as to improve extrusion process, preventing growth, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Ball milling modification of raw materials

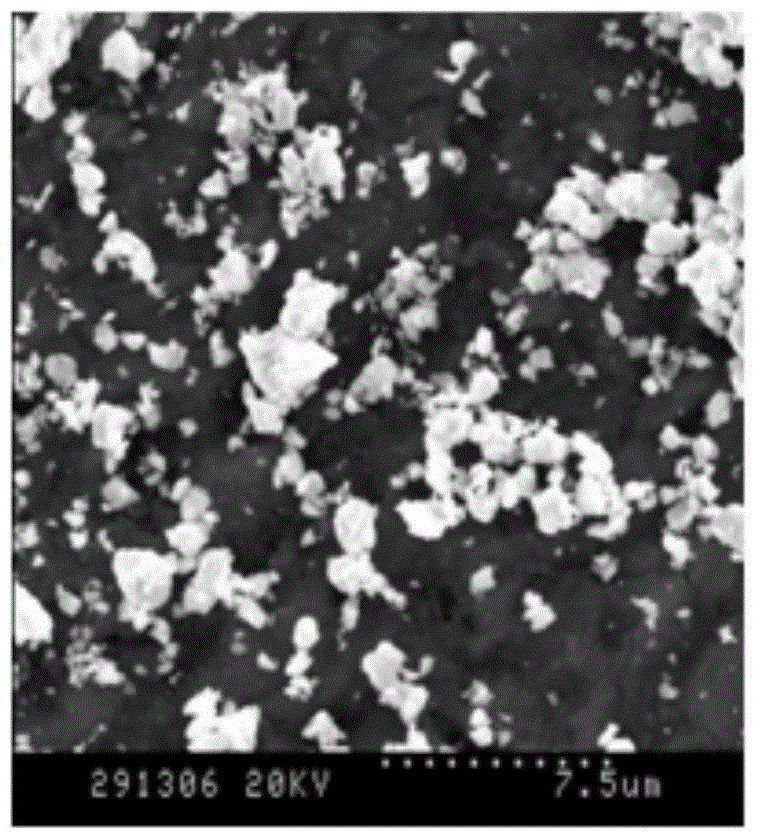

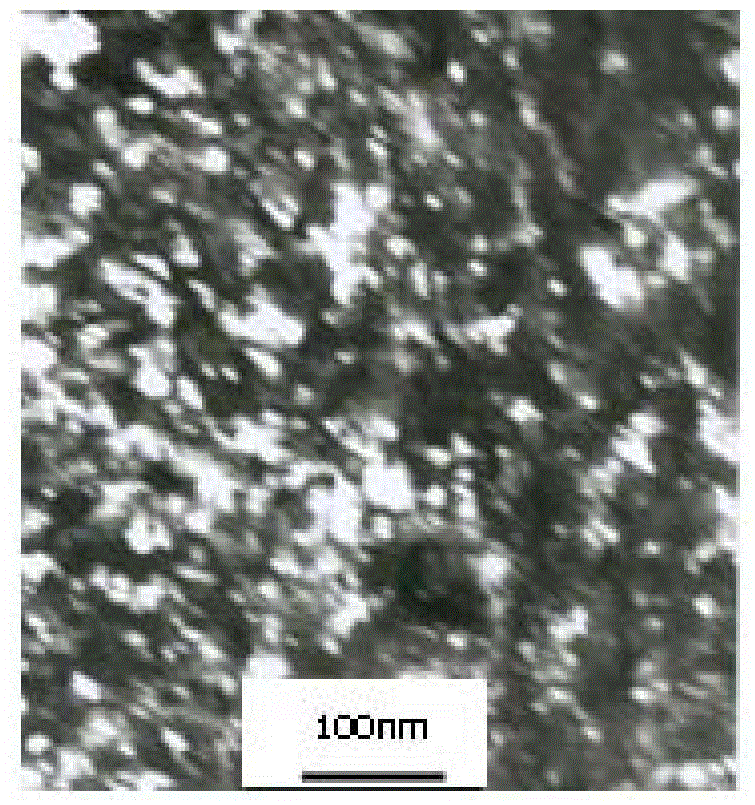

[0048] Put the reduced tungsten powder into a high-energy stirring ball mill for ball milling. During the ball milling, high-purity argon with a purity of 99.99% is used as a protective gas, and 1wt% stearic acid is added as a ball milling process control agent. The ball material is GCr15 , its diameter is about 6mm, the ball-to-material ratio (mass ratio) is about 15:1, and the ball mill speed is controlled to be about 350rpm, the ball milling time is about 35h, and the modified tungsten powder (powder output) with an average size of submicron is obtained. rate is about 94.3%), and the scanning electron microscope results are as follows figure 1 shown. Depend on figure 1 It can be seen that the tungsten particles modified by ball milling have been significantly refined, and the shape of the particles tends to be "equiaxed". The size reaches about 14nm.

[0049] Carbonyl nickel powder and carbonyl iron powder are prepa...

Embodiment 2

[0061] 1. Ball milling modification of raw materials

[0062] Put the reduced tungsten powder into a high-energy stirring ball mill for ball milling. During the ball milling, high-purity argon is used as the protective gas. The ball material is GCr15, with a diameter of about 6mm and a ball-to-material ratio of about 10:1. The rotating speed is about 300rpm, the ball milling time is about 25h, and the modified tungsten powder (the powder yield is about 96.3%) is obtained, and the grain size reaches about 34nm.

[0063] The carbonyl nickel powder and carbonyl iron powder are prepared into a mixed powder according to the mass ratio of about 6:4, and then placed in a powder mixer to mix evenly, and then placed in a high-energy stirring ball mill for ball milling. High-purity argon is used for ball milling Gas is used as the protective gas, the ball material is GCr15, its diameter is about 6mm, the ball-to-material ratio is about 10:1, and the speed of the ball mill is controlled ...

Embodiment 3

[0073] 1. Ball milling modification of raw materials

[0074]Put the reduced tungsten powder into a high-energy stirring ball mill for ball milling. During the ball milling, high-purity argon is used as the protective gas. The ball material is GCr15, with a diameter of about 6mm and a ball-to-material ratio of about 15:1. The rotation speed is about 250rpm, and the ball milling time is about 20h, and the modified tungsten powder is prepared, and the grain size reaches about 117nm.

[0075] Carbonyl nickel powder and carbonyl iron powder are prepared into mixed powder according to the mass ratio of about 8:2, and then placed in a powder mixer to mix evenly, and then placed in a high-energy stirring ball mill for ball milling. High-purity argon is used for ball milling Gas is used as the protective gas, the ball material is GCr15, its diameter is about 6mm, the ball-to-material ratio is about 15:1, and the speed of the ball mill is controlled at about 250rpm, and the ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com