Sealing strip, filtering frame, filtering frame assembly and filtering equipment

A technology of sealing strips and components, which is applied in the field of filter presses and can solve problems such as increasing the cycle time of the filtration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

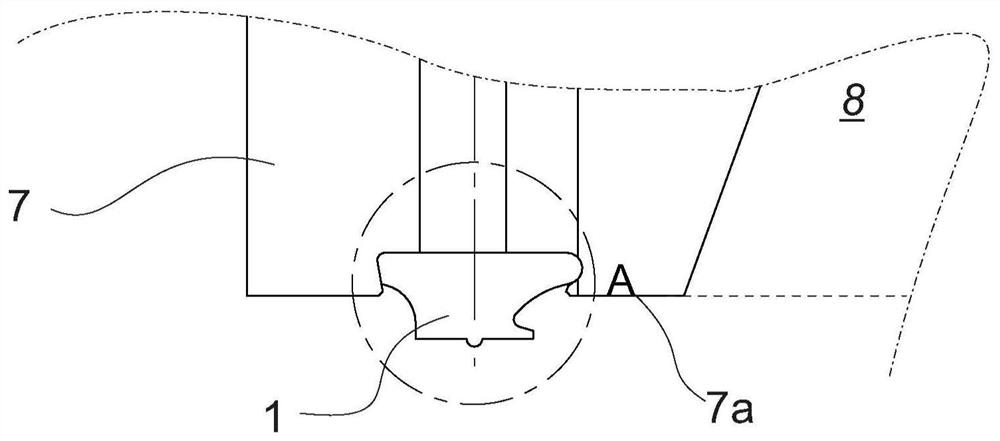

[0071] According to a first aspect of the present disclosure there is provided a sealing strip for sealing adjacent filter plate assemblies of a filter press, eg a horizontal filter press, eg a tower press.

[0072] Such horizontal filter presses are generally used for filtering slurries fed into the filter chamber with a filter pressure differential of 8-20 bar, typically about 12 bar, relative to ambient pressure. In order to achieve an adequate seal at the interface between adjacent filter frame assemblies, the sealing strip must withstand a linear load of 30-300N / mm, typically between 100-150N / mm.

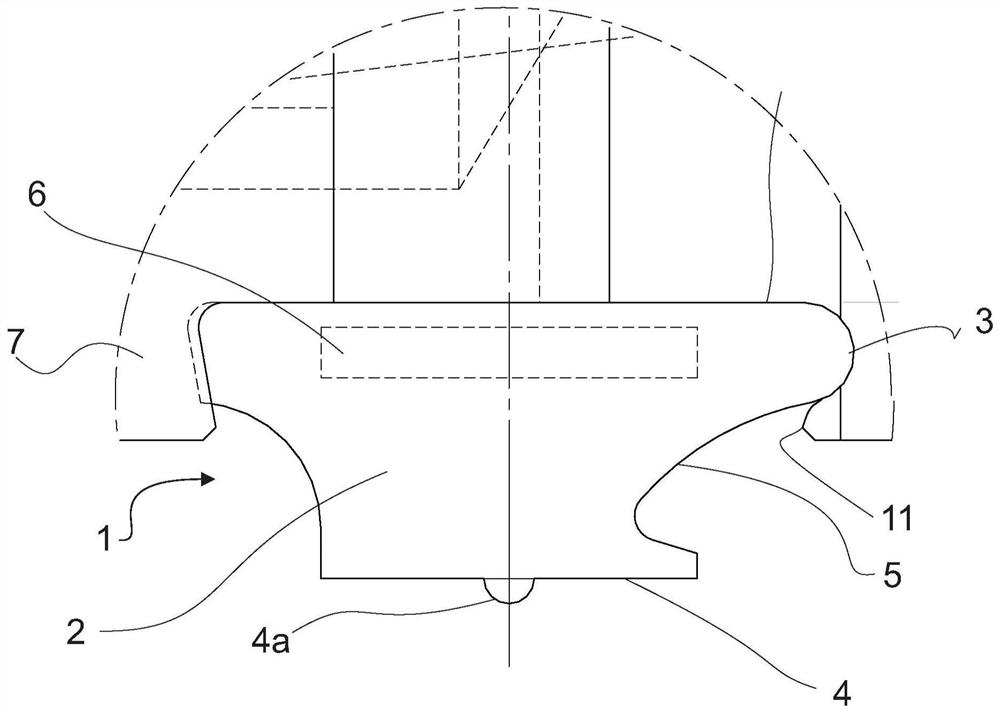

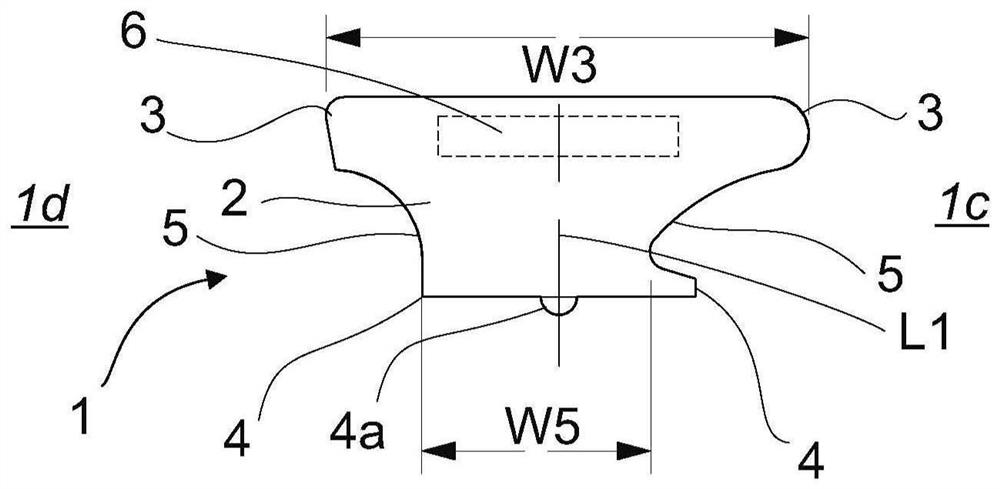

[0073] The weather strip 1 comprises an elongated body 2 extending in a lengthwise direction and having a first longitudinal end 1a and a second longitudinal end 1b.

[0074] The cross-sectional profile of the elongated body 2 includes a base portion 3 which is attached in a corresponding groove 9 of an associated filter frame or filter panel assembly. The cross-sectional prof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com