Improved Carius tube assembly

A type of Carlos tube and component technology, applied in the field of improved Carlos tube components, can solve the problems of rusty substances falling and polluting samples, easily polluted samples, and inaccurate test results, so as to reduce the risk of experimental accidents and avoid cleaning. In place, reduce the effect of data inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

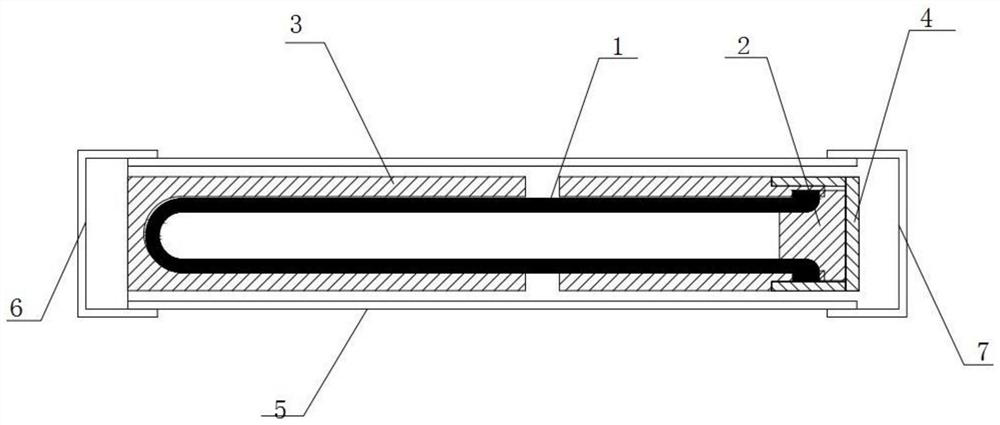

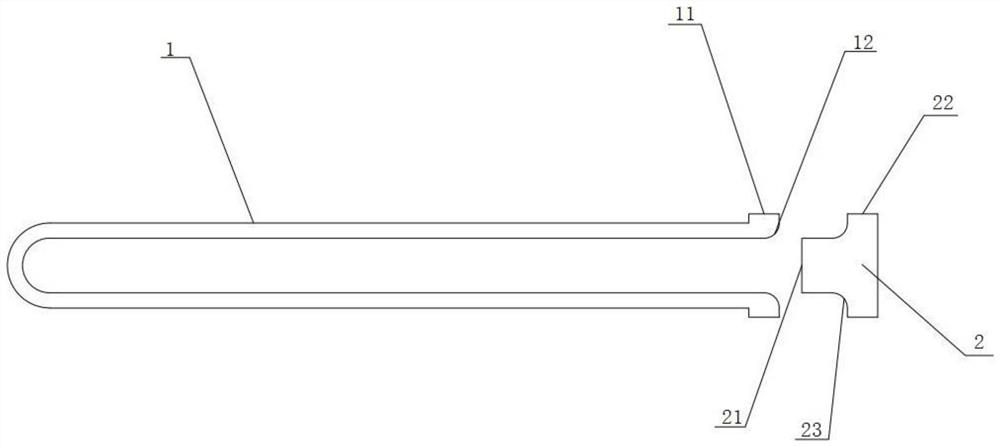

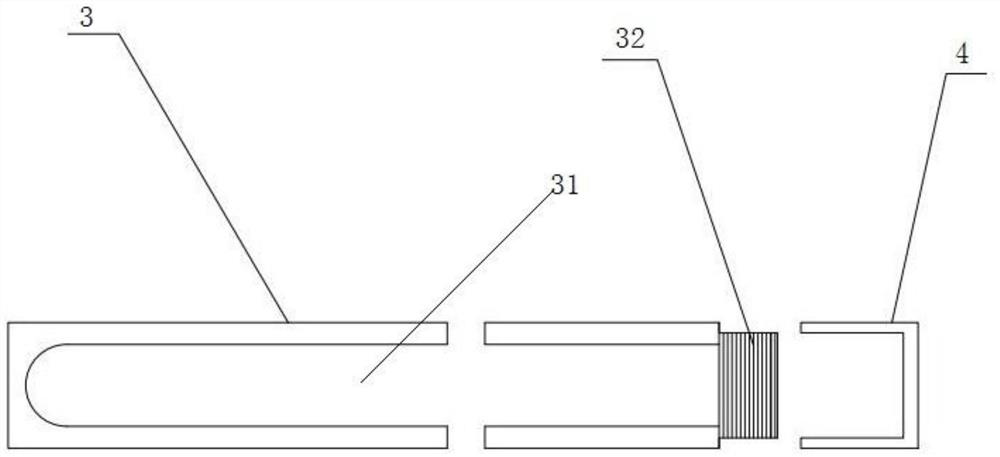

[0024] Such as Figure 1 to Figure 3 As shown, an improved Carlos tube assembly of the present invention includes a tube body 1, a tube plug post 2, a sleeve 3 and a sleeve cover 4, wherein the material of the tube body 1 is consistent with the existing equipment, and the tube body 1 The mouth is provided with an annular rib 11, and the mouth of the annular rib 11 and the pipe body 1 is provided with an opening 12 with an arc-shaped cross section; the pipe plug 2 includes a cylinder 21 and a sealing rib 22, and the cylinder 21 and the sealing rib There is an arc-shaped sealing part 23 corresponding to the opening 12 between the sides 22; the sleeve 3 is provided with an inner cavity 31 corresponding to the pipe body 1, and the upper part of the sleeve 3 is provided with an external thread 32; An internal thread corresponding to the external thread 32 is provided; the sleeve 3 is a two-section split structure, that is, the sleeve 3 is composed of two unconnected sleeves.

[00...

Embodiment 2

[0028] Such as Figure 1 to Figure 4 As shown, different from Embodiment 1, an improved Carlos tube assembly of the present invention also includes an explosion-proof sleeve 5, a left end cover 6 and a right end cover 7, and the two ends of the explosion-proof sleeve 5 are respectively provided with a left interface. Thread 51 and right interface external thread 52; left end cap 6 is provided with left internal thread corresponding to left interface external thread 51; right end cap 7 is provided with right internal thread corresponding to right interface external thread 52. When in use, put the pipe body 1 and sleeve pipe 3 of embodiment 1 into the explosion-proof casing 5, tighten the left end cap 6 and the right end cap 7, so that the pipe body 1 and the sleeve pipe 3 are completely enclosed in the explosion-proof casing 5, Then put the whole into an oven and heat it at a constant temperature below 185°C for a certain period of time, and then take it out for subsequent expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com