Green sand device for bench vice channel steel and forming method thereof

A technology of green sand and bench vise, which is applied in the direction of casting mold composition, casting molding equipment, casting mold, etc., can solve problems such as iron penetration defects, achieve the effect of reducing storage costs, reducing processing costs, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

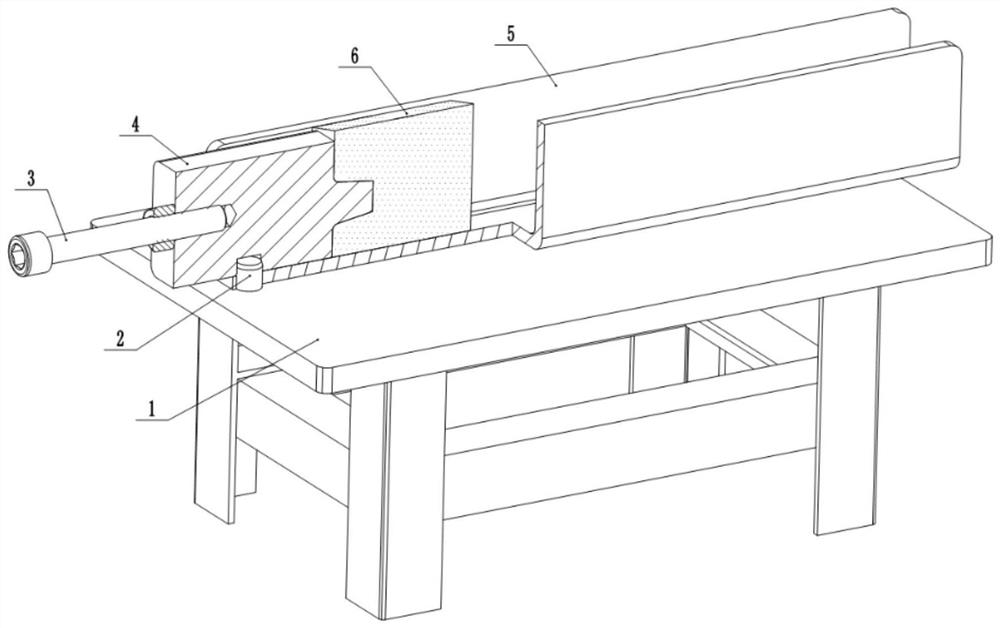

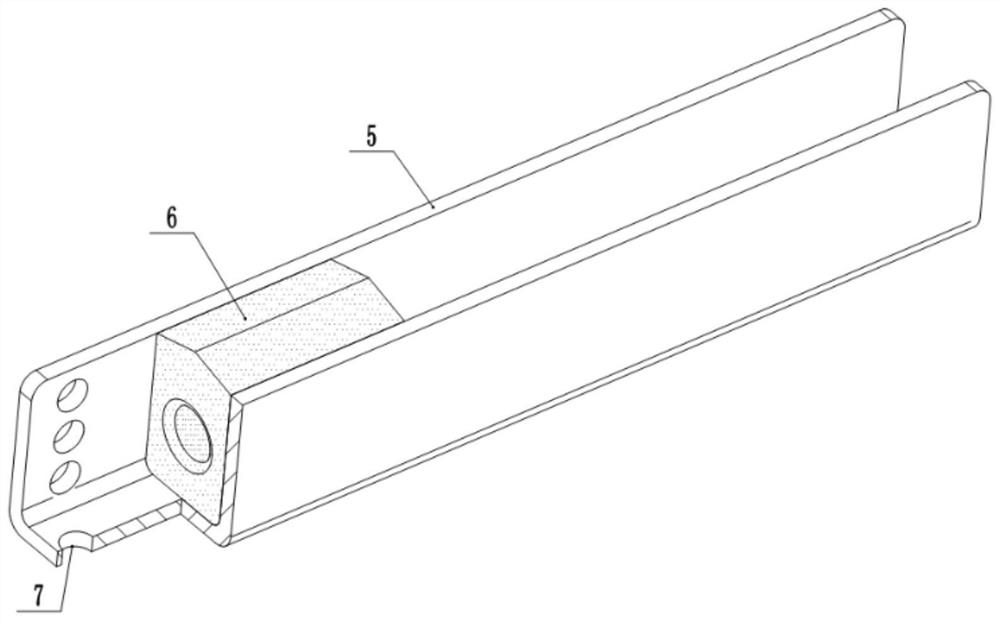

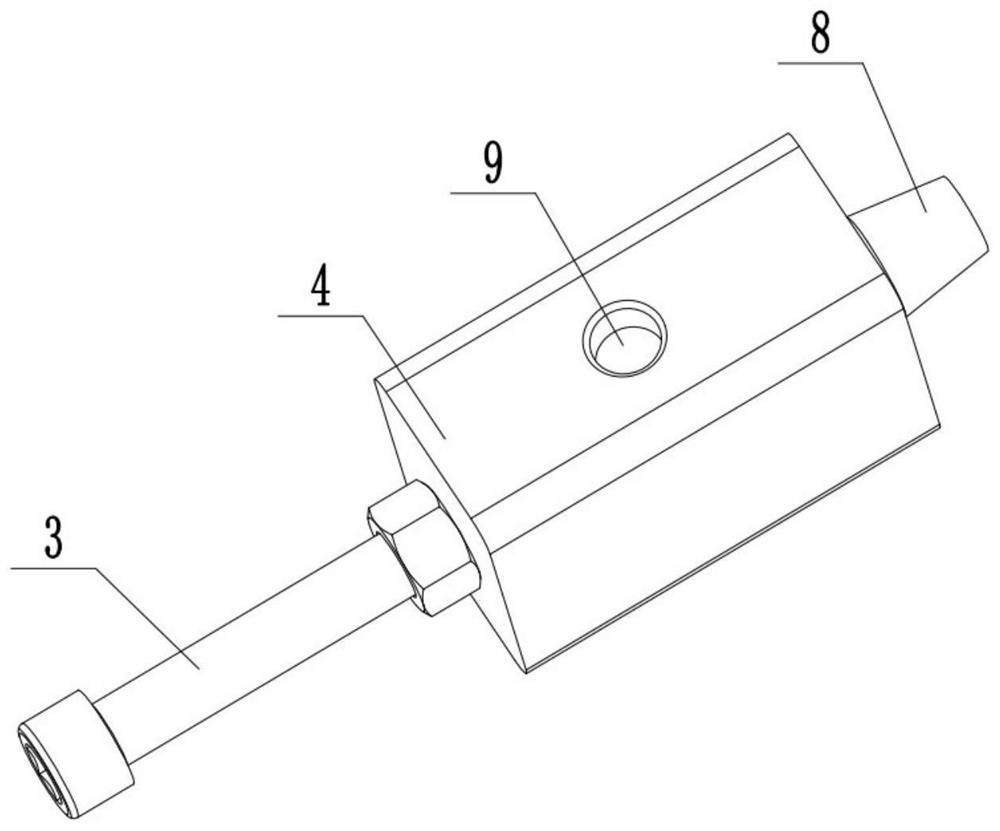

[0037] Please refer to Figure 1 to Figure 3 , a green sand device for bench vise channel steel, comprising a workbench 1, a loose block 4 and a channel steel 5, the lower end of the workbench 1 is provided with a support frame, and the end of the workbench 1 is provided with Locating pin 2, can guarantee the support effect to channel steel 5, conveniently takes and puts loose block 4, and the bottom of described channel steel 5 and loose block 4 is respectively provided with corresponding positioning hole one 7 and positioning hole two 9, channel steel 5 and the movable block 4 are placed on the workbench 1, the positioning pin 2 is sequentially inserted into the positioning hole 7 and the positioning hole 2 9 from bottom to top, and the channel steel 5 is provided with a housing for the movable block 4 The U-shaped groove, the U-shaped groove is provided with a sand tire 6 made of green sand, and the contact between the movable block 4 and the sand tire 6 is provided with a ...

Embodiment 2

[0042] Please refer to Figure 4 to Figure 5 , is different from Embodiment 1 in that it also includes a sand scraping plate 10 for the sand scraping tire 6, and the rest is the same as Embodiment 1.

[0043] A green sand device for bench vise channel steel, further comprising a sand scraper 10, a groove 10-1 is provided on the sand scraper 10, and empty knives are arranged on both sides of the groove 10-1 Groove 10-2, the empty knife groove 10-2 is inserted on the outer wall of the U-shaped groove. After the green sand is extruded, the sand scraping plate 10 is clamped on the outside of the U-shaped groove, and the sand scraping plate 10 is manually pushed to move along the length direction of the channel steel 5, thereby scraping off excess loose sand on the sand tire 6, Simultaneously, the groove 10-1 structure on the sand scraping plate 10 ensures that the height of the upper end of the sand tire 6 is slightly higher than the height of the U-shaped groove sidewall.

[00...

Embodiment 3

[0046] The present invention also discloses a method for forming green sand, which adopts the above-mentioned green sand device and includes the following steps:

[0047] Mix molding sand and water evenly to form green molding sand, the humidity of the green molding sand is 2.9%-3.2%, and the compaction rate is 35%-40%. When the humidity is lower than 2.9%, the molding sand is not fully wetted, it is difficult to remove the mold, the sand mold is fragile, and the casting is prone to sand holes and erosion defects; when the humidity is greater than 3.2%, it is easy to cause pinholes, pores and stickiness in the casting Sand and other defects, the humidity is preferably 3%, and the compaction rate is preferably 38%.

[0048] The channel steel 5 and the movable block 4 are sequentially inserted on the positioning pin 2 of the workbench 1, that is, the first positioning hole 7 and the second positioning hole 9 are sleeved on the positioning pin 2, and the movable block 4 is placed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com