Weld joint back surface gas protection and forming device for pipeline welding and application thereof

A gas shielding and forming device technology, which is applied in the direction of providing/removing shielding gas devices, welding accessories, etc., can solve the problem of not being able to take into account the formation of the back of the weld and gas protection, etc., to reduce the difficulty of welding for welders, simple structure, reduce The effect of shielding gas volume on the back of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

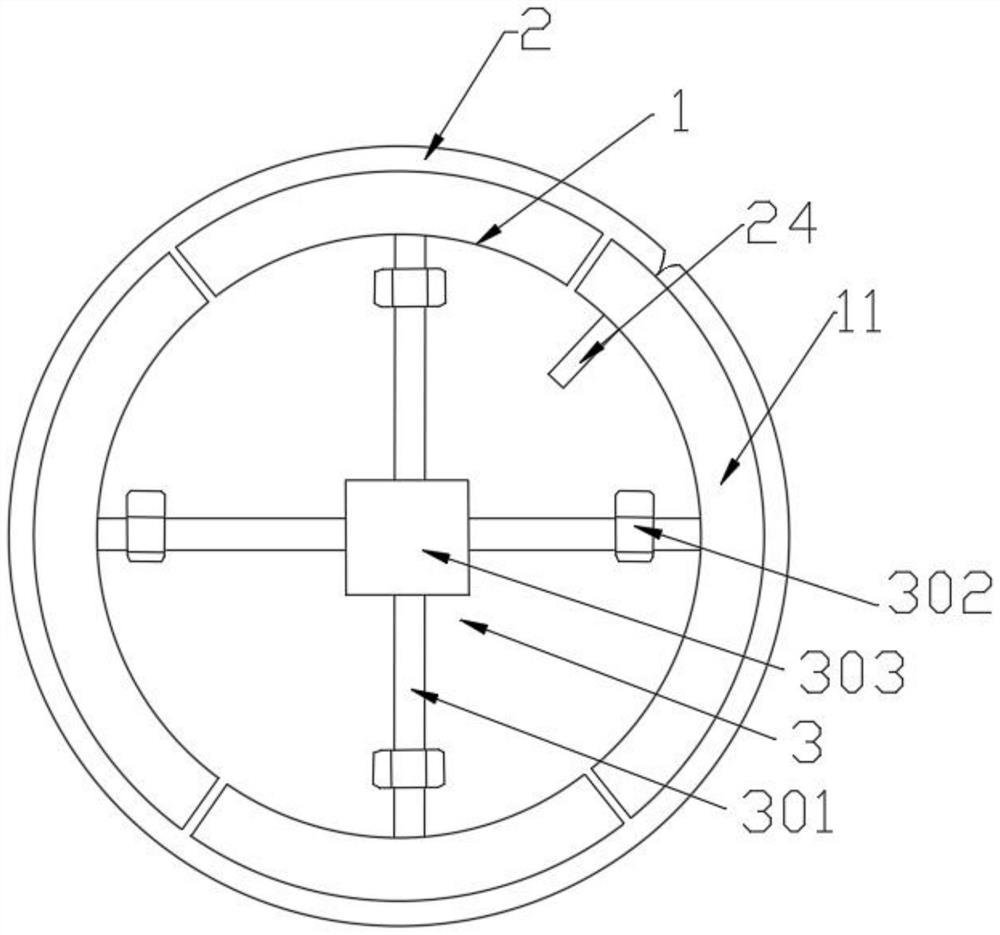

[0043] Please refer to Figure 1-4 , This embodiment takes the typical case of four arc-shaped seats to describe in detail the gas protection and forming device for the back of the weld for pipeline welding of the present invention.

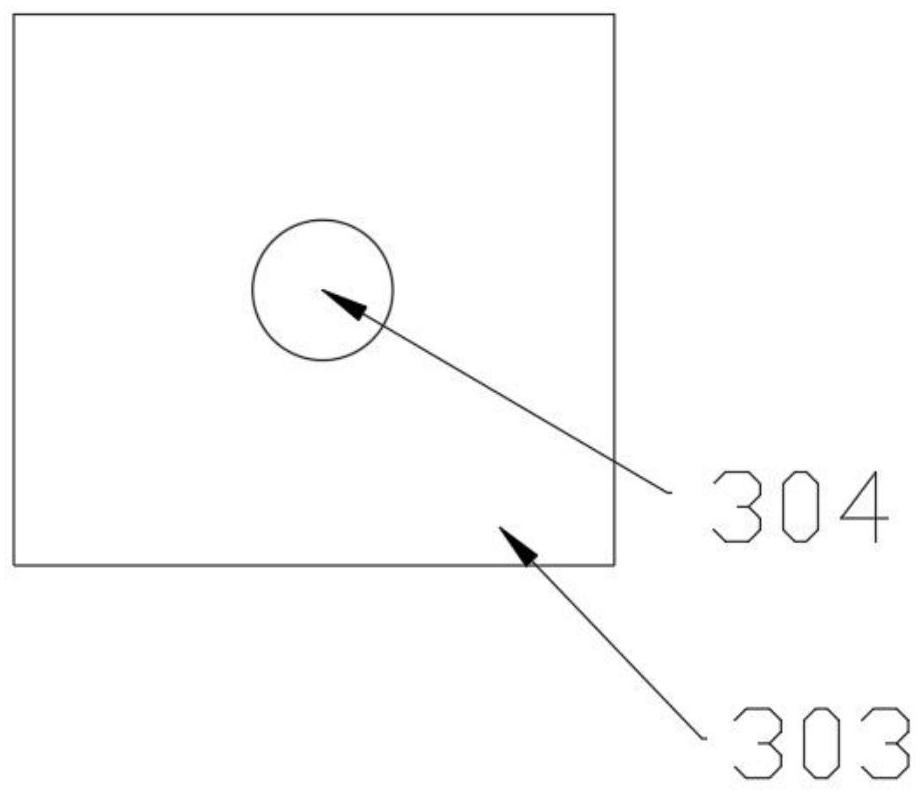

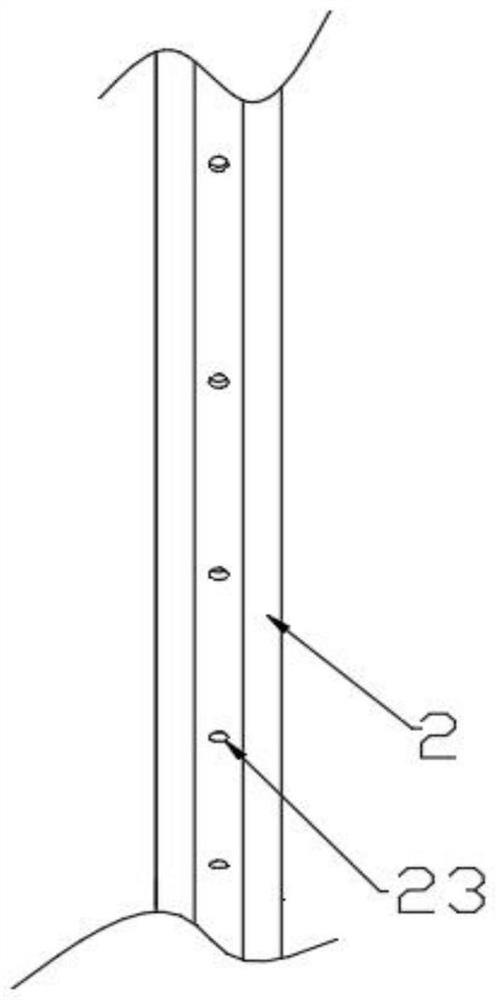

[0044] The device includes a molding base 1 and a ring-shaped gasket 2 arranged outside it, wherein the molding base includes 4 arc-shaped seats 11, and the arc-shaped seats 11 are arranged at intervals in a circle, and the distance between them is 3-4mm. The inner side of the shaped seat body 11 is connected with a lifting adjustment mechanism 3, and the arc-shaped seat body 11 realizes scaling in the radial range of the molding base 1 through the lifting adjustment mechanism 3; in this embodiment, the lifting adjustment mechanism includes a screw rod 301, and the A nut 302 is fixedly sleeved on the screw rod 301, and the nut 302 can be fixed by a self-locking nut. One end of the nut 302 is connected to the arc-shaped base body 11, and the other...

Embodiment 2

[0049] This embodiment provides a method for welding pipelines using the gas protection and forming device described in Embodiment 1, including the following steps:

[0050] Place the device under the pipe groove, and place the welding groove gap in the middle of the forming groove;

[0051] Adjust the nut, and push the arc-shaped base to squeeze outward through the rotation of the screw rod, so that the liner fits with the back of the tube;

[0052] Insert the ventilation hose into the air inlet placed under the tooling;

[0053] According to the length of the pipeline, choose to wrap the traction rope on the device;

[0054] Open the inert gas valve, perform gas shielding, and start welding;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com