Pneumatic wrench

A technology of pneumatic wrench and airway, applied in the field of pneumatic wrench, which can solve the problems of cumbersome operation process of rotating handle, complex structure of pneumatic wrench, and limitation of rotation angle, etc., and achieve convenient and fast operation process, simple and light overall structure, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

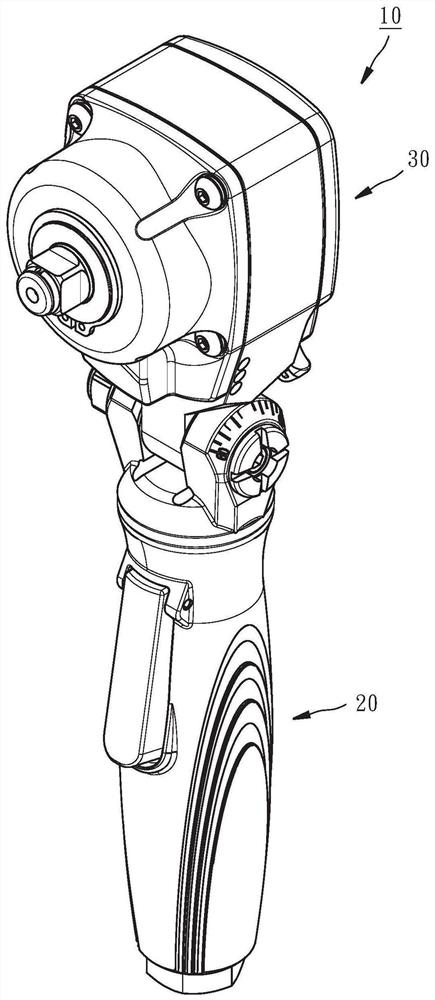

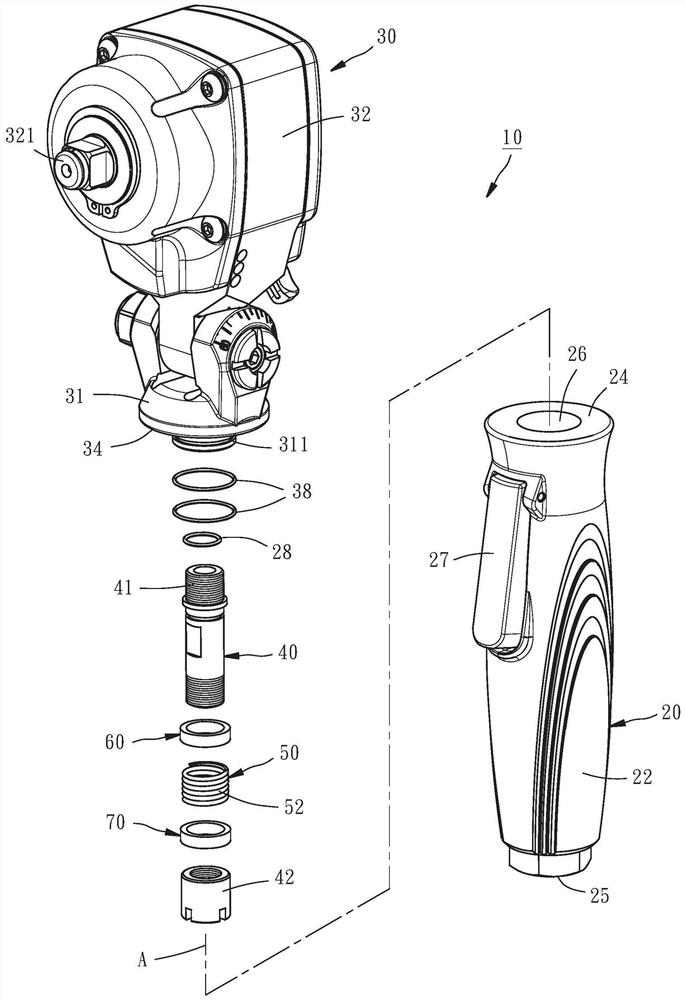

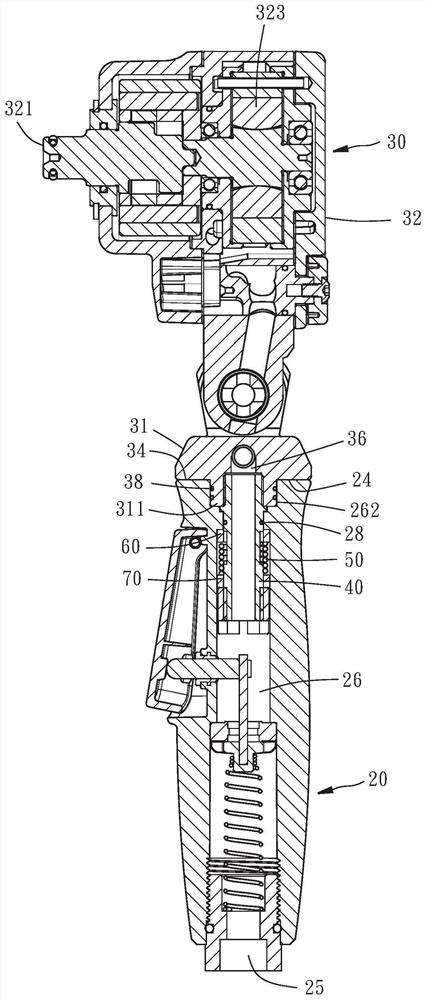

[0028] The technical contents and features of the present invention will be described in detail below through a preferred embodiment in conjunction with the accompanying drawings, as figure 1 , figure 2 Shown is an air wrench 10 provided by a preferred embodiment of the present invention, which includes a handle 20 , a tool head 30 , a pipe 40 , a compression spring 50 , an upper washer 60 , and a lower washer 70 .

[0029] The handle 20 has a cylindrical body 22, a first annular surface 24 positioned at the upper end of the body 22, an air inlet 25 positioned at the lower end of the body 22, an air inlet 25 that passes through the body 22 and connects with the air inlet. The lower air passage 26 communicated with the mouth 25, a push button 27, and an airtight ring 28. Please refer to image 3 , Figure 4 , the lower airway 26 has a narrow opening 261, an upper chamber 262 communicating with the narrow opening 261, a lower chamber 263 communicating with the narrow opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com