Hoisting and installing equipment for glass fiber reinforced plastic isolation piers

A technology for installing equipment and isolating piers, which is used in transportation and packaging, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as low work efficiency, affect the effect of lifting and installation, and inconvenient maintenance, and improve work efficiency. , The effect of increasing the carrying capacity and continuous operation capacity, and facilitating subsequent installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

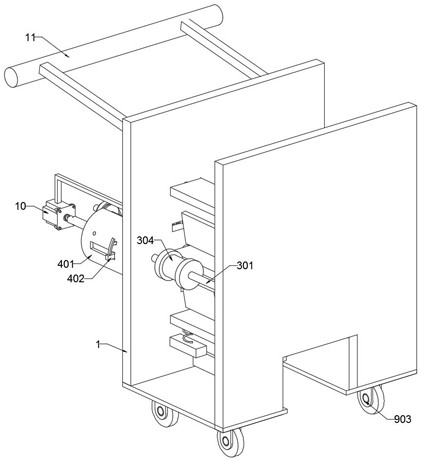

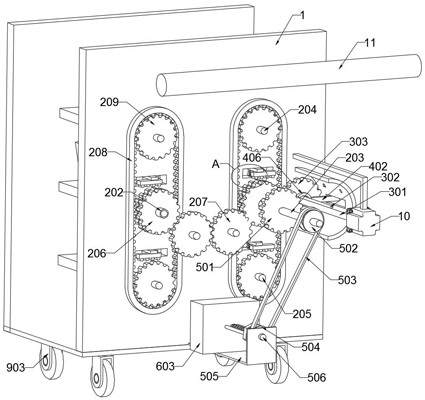

[0027] refer to Figure 1-5 , a kind of hoisting and installation equipment used for FRP isolation pier, comprising a chassis 1, the inner wall of the chassis 1 is provided with a feeding mechanism;

[0028] The unloading mechanism includes a round tube 202 that is symmetrically penetrated and rotatably connected to the inner wall of the cabinet 1. The inner wall of the round tube 202 is slidably connected with a support rod 203, and the side wall of the cabinet 1 is connected with a first connecting rod 204 for symmetrical rotation. The side wall of the cabinet 1 is connected with a symmetrical rotation. The second connecting rod 205, the round pipe 202, the first connecting rod 204 and the side walls of the second connecting rod 205 are all fixedly connected with a first gear 209, and the three first gears 209 on the same side are meshed together and connected with an endless toothed belt 208 The inner wall of the cabinet 1 is connected with a third gear 207 for symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com