Ultrathin material etching device

An etching device and ultra-thin technology, which are used in the removal of conductive materials by chemical/electrolytic methods, electrical components, and printed circuit manufacturing. It can solve problems such as uneven etching, uneven tension, and wrinkling, and avoid excessive etching. , The effect of improving etching accuracy and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

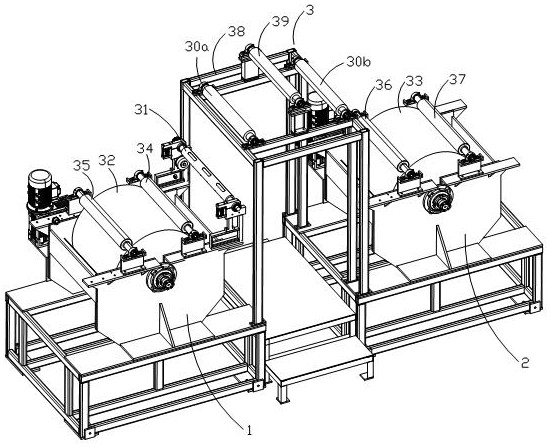

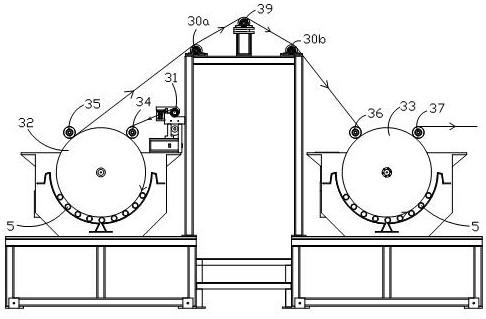

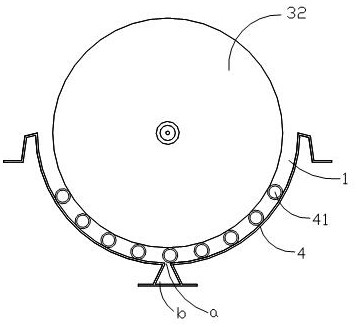

[0040] see Figure 1-5 As shown, the embodiment of the present invention discloses an ultra-thin material etching device, which includes a first etching tank 1, a second etching tank 2, a roll conveying mechanism 3, a first spraying mechanism 4 and a second spraying mechanism 5, The first etching groove 1 and the second etching groove 2 are arranged side by side, and the material roll conveying mechanism 3 is used to convey and support the material to be etched into the first etching groove 1 and the second etching groove 2 in order to make the material to be etched enter the first etching groove 1 and the second etching groove 2 Carry out front etching, carry out reverse etching in the second etching tank 2, the first shower mechanism 4 and the second shower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com