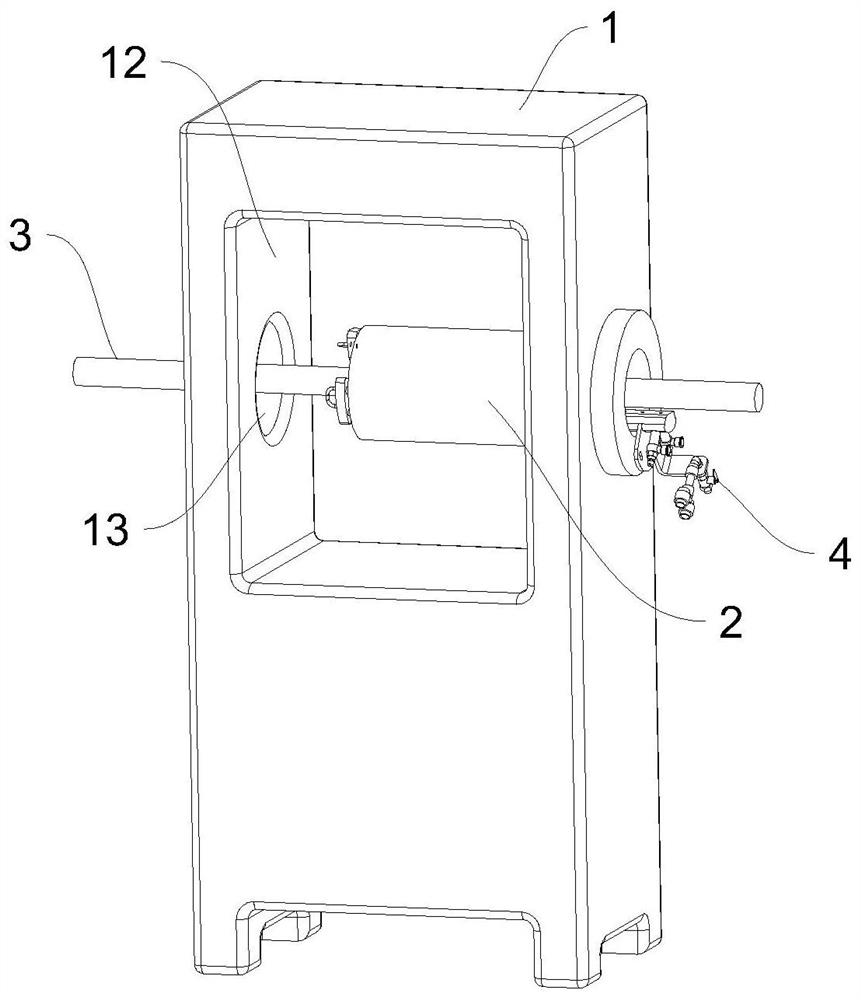

Airflow driving device of silica gel knitting machine

An airflow-driven, knitting machine technology, applied in the field of silicone tubes, can solve problems affecting the normal operation of knitting machines and difficult passage of silicone tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

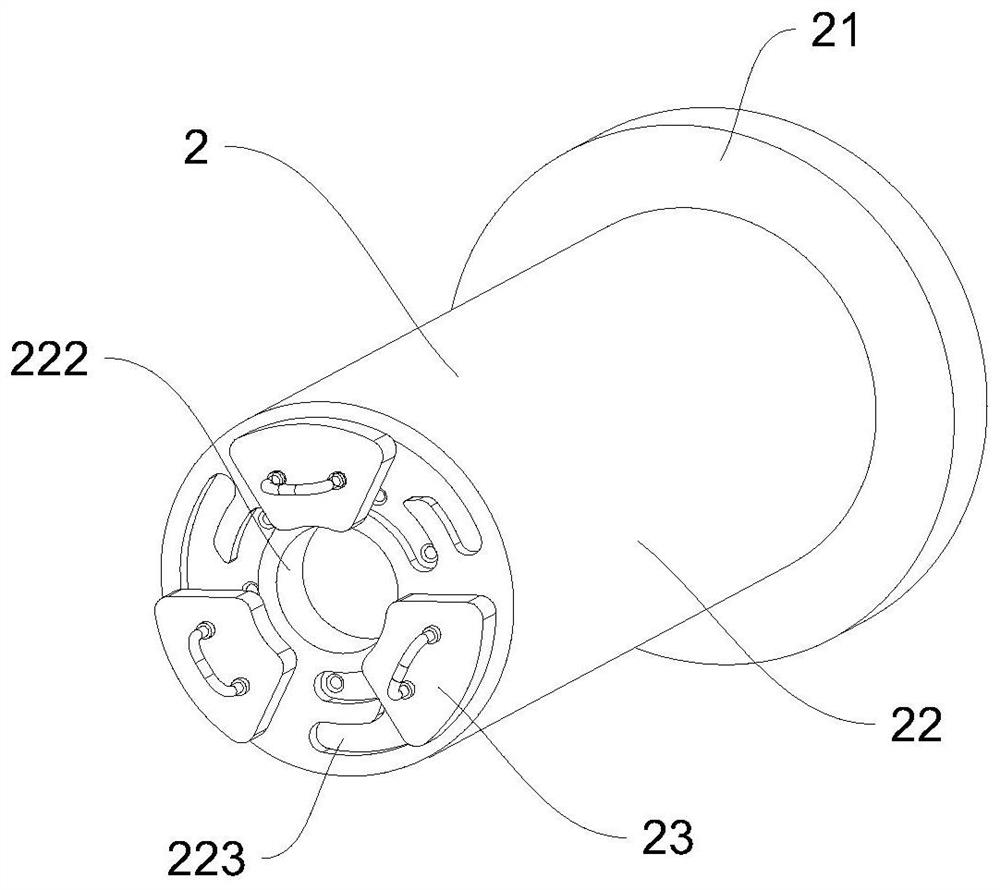

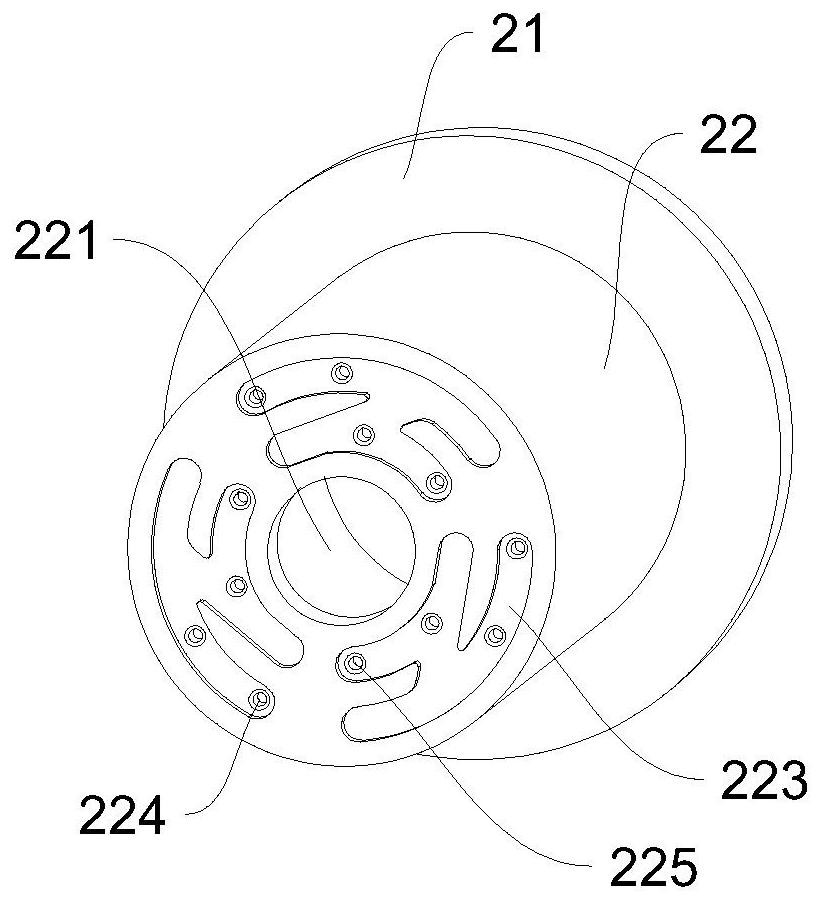

[0032] As an embodiment of the present invention, the sleeve 2 is composed of a limit seat 21 and a shell 22; the limit seat 21 is fixedly connected to one end of the shell 22; the limit seat 21 is fixedly connected to a fixed On the outer wall of the seat 1; the inside of the shell 22 is provided with a No. 1 cavity 221; the side wall of the end of the shell 22 away from the limit seat 21 is provided with a No. 2 through hole 222; the No. 2 through hole 222 communicates with the first cavity 221.

[0033] When working, the No. 1 cavity 221 inside the sleeve 2 can fill the No. 1 cavity 221 with gas when the blowing assembly 4 blows air. When filling its interior, after supporting the silicone tube body 3, it will further support the silicone tube body 3 along the inner wall of the first cavity 221, thereby enhancing the supporting effect of the airflow on the silicone tube body 3 and avoiding hot melt. The silicone tube body 3 is deformed during the movement and adheres to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com