DPF carrier carbon deposition cleaning device

A cleaning device, DPF technology, applied in the direction of the muffler, exhaust device, engine components, etc., can solve the problems of secondary pollution, exhaust back pressure increase, affecting engine power and fuel economy, etc., to achieve carbon removal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

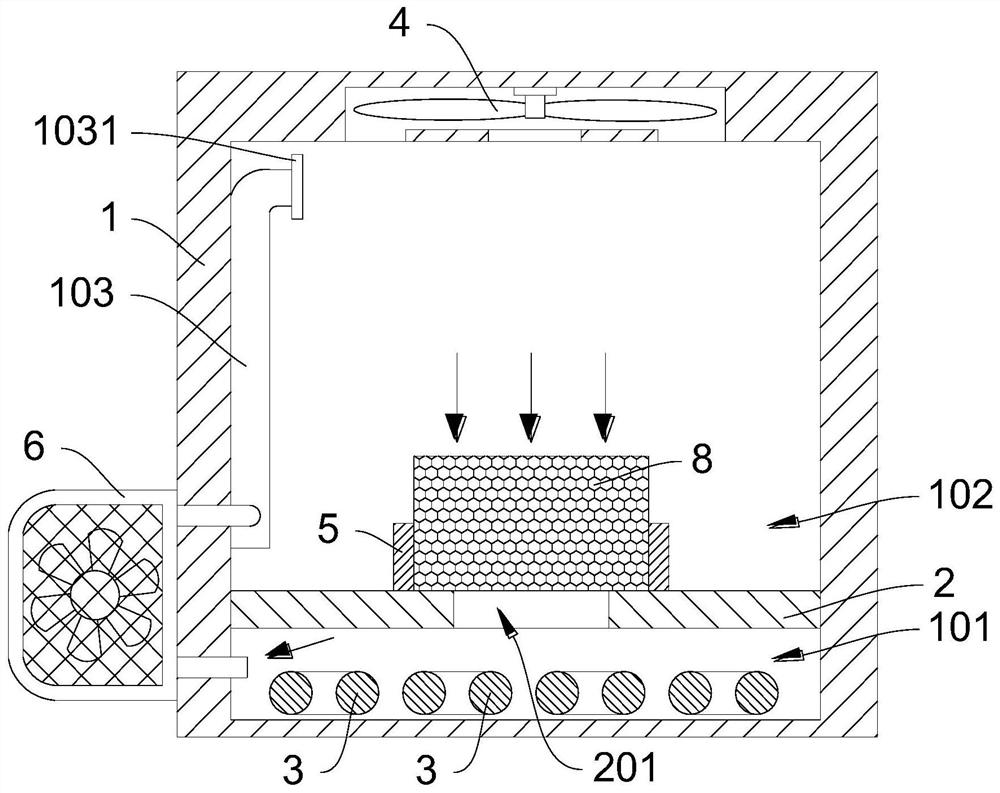

[0033] Please refer to Figure 1 to Figure 4 , shows a DPF-loaded volume carbon cleaning device provided by an embodiment of the present invention, and the specific structure is as follows.

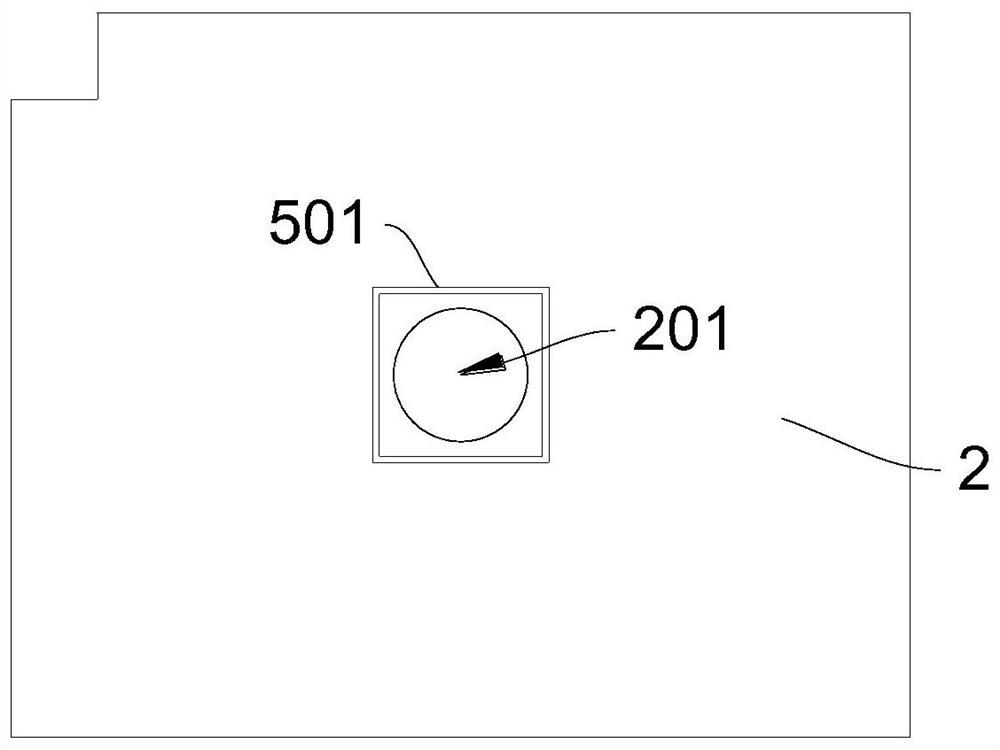

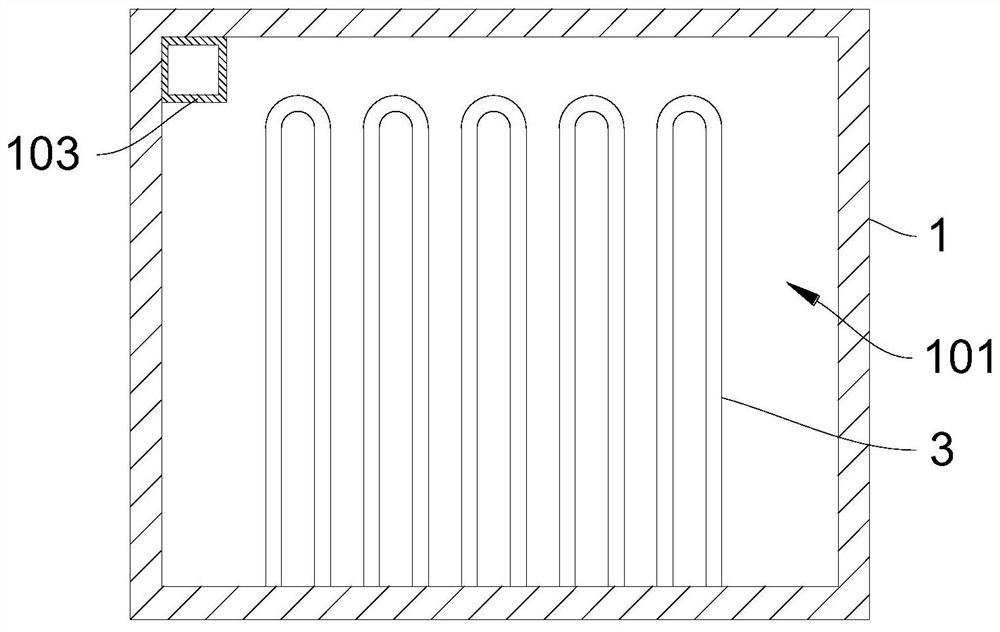

[0034] Such as figure 1 , the embodiment of the present application provides a DPF carrier volume carbon cleaning device, which includes a box body 1 and a partition plate 2 arranged in the box body 1, a heating assembly 3, and a directional air supply assembly, and the inside of the box body 1 is separated by a partition plate 2 Divided into a first chamber 101 and a second chamber 102, the heating assembly 3 is arranged in the first chamber 101, the directional air supply assembly communicates with the first chamber 101 and the second chamber 102, and the partition plate 2 is provided to communicate with the first chamber. The cavity 101 and the through hole 201 of the second cavity 102 . combine figure 1 As shown, the box body 1 provides a closed place for the DPF carrier to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com