Valve rod assembly with coupling cavity

A coupling cavity and valve stem technology, applied in engine components, machines/engines, charging systems, etc., can solve problems such as reducing the service life of the injector, needle valve bounce, and complex structure, reducing impact and improving Effects on reliability and part life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

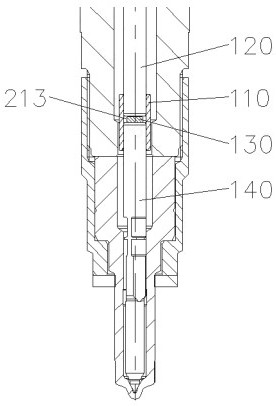

[0018] Such as Figure 1 to Figure 4 As shown, a valve stem assembly with a coupling cavity adopts a new structural design. By setting a connecting sleeve and an adjusting pad between the control rod and the needle valve, when the control rod moves upward, the control rod and the connecting sleeve Moving together, the needle valve creates a slight gap between the sleeve, pad and lever. Due to the negative pressure formed in the coupling cavity, a small amount of fuel will enter the coupling cavity. When the control rod moves downward to close the fuel injection state, the small amount of fuel in the coupling cavity acts as a buffer, reducing the impact of the needle valve on the seat surface, reducing the impact load of the needle valve, needle valve body, control rod and adjustment pad, Improved reliability and part life. It includes a needle valve body structure 140, the upper end of the needle valve body structure 140 is matched with a cylindrical adjustment pad 130, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com