Synchronous two-stage compressor

A two-stage compressor and compression chamber technology, applied in the field of compressors, can solve the problems of easy damage of sealing ring components, reduce the power of the motive force, gas leakage, etc., and achieve the effects of small occupied space, reduced load and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

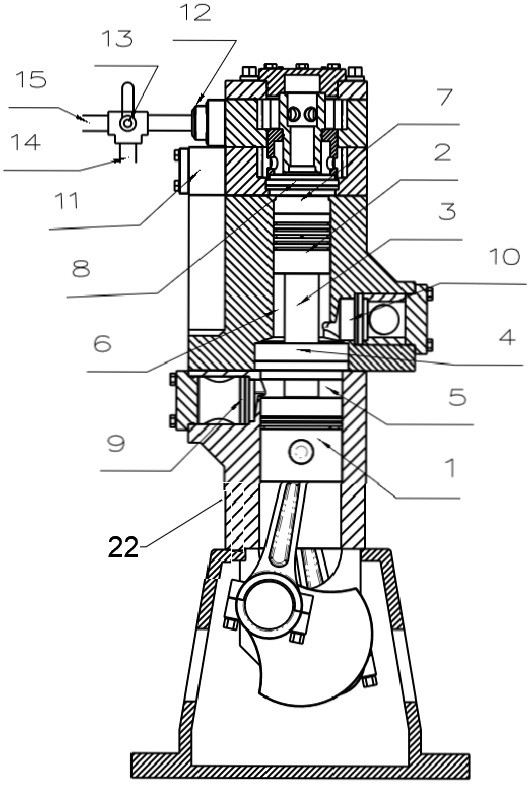

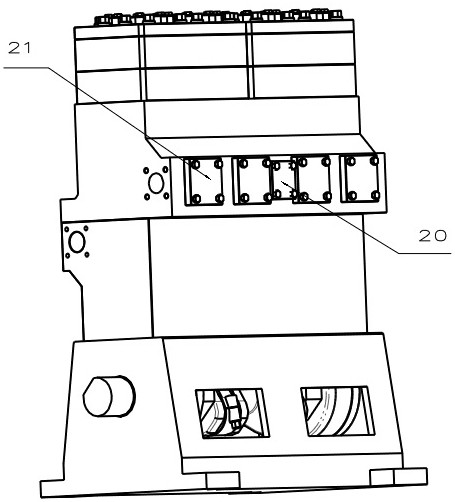

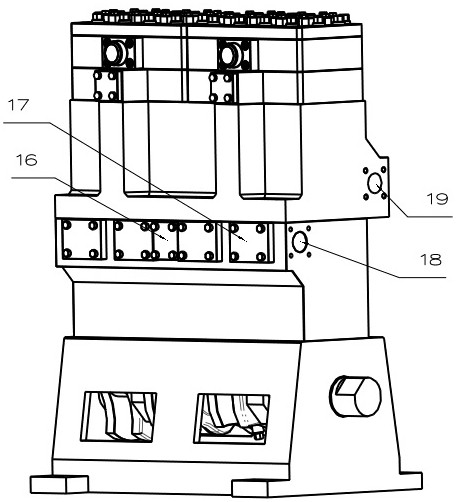

[0028] Figure 1-3 A preferred embodiment of a synchronous two-stage compressor of the present invention is shown. The synchronous two-stage compressor in this embodiment specifically includes a cylinder block 22, and the cylinder block 22 has a plurality of cylinders arranged in a straight line inside, so The cylinder is provided with a compression chamber, and the compression chamber is provided with a secondary piston 2 sequentially arranged from top to bottom, an inter-stage check valve 4 with a central hole, and a primary piston 1. The primary piston 1 The linkage between the two-stage piston 2 and the synchronous shaft 3 is realized. The middle part of the inter-stage check valve 4 is provided with a central hole for accommodating the synchronous shaft 3. In the compression chamber, the first-stage piston 1 and the inter-stage one-way The first compression chamber 5, the second compression chamber 6 and the third compression chamber are formed between the valves 4, betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com