High-pressure oil pipe with anti-explosion function

A high-pressure oil pipe, functional technology, applied in the field of high-pressure oil pipe with explosion-proof function, can solve the problems of oil pipe burst, inconvenient oil pipe connection, oil pipe damage, etc., and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

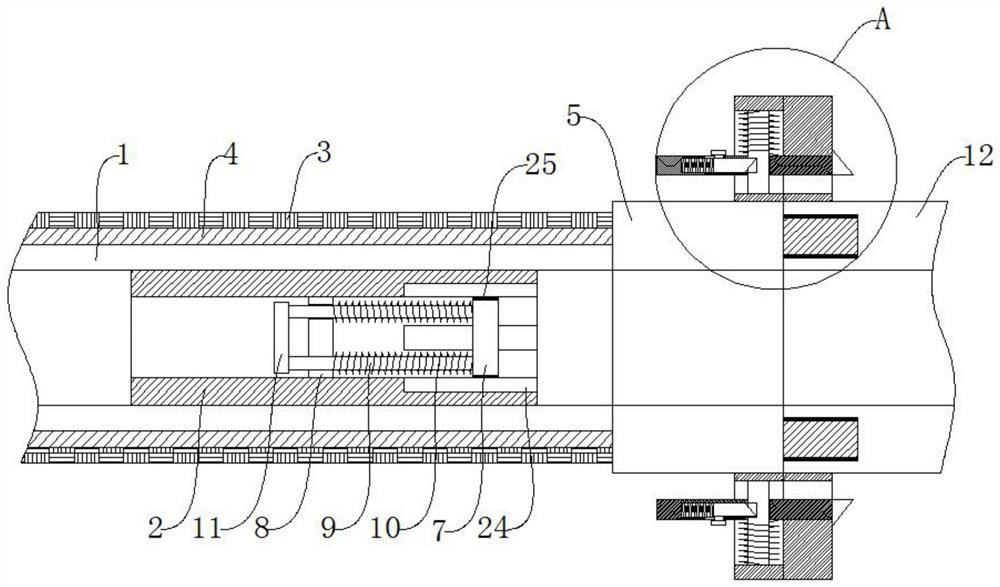

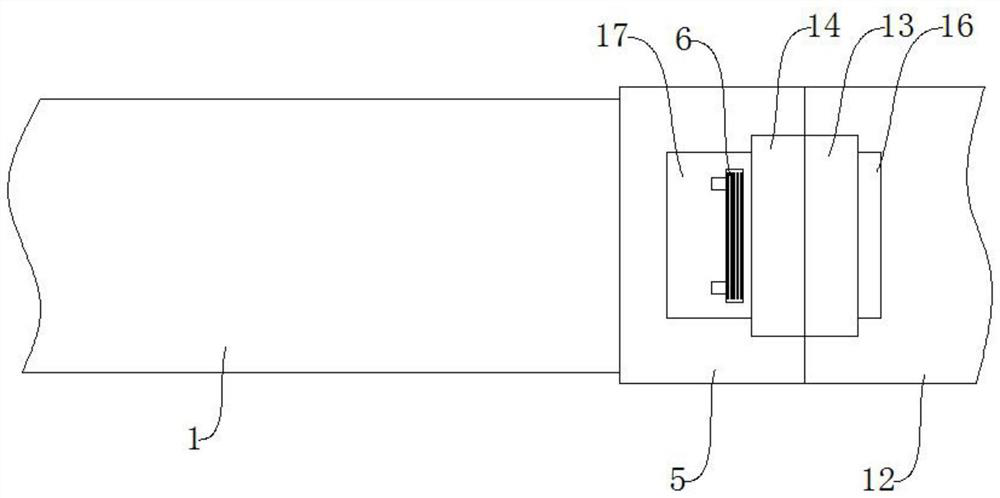

[0024] refer to Figure 1-3 , a high-pressure fuel pipe with explosion-proof function, comprising a fuel pipe main body 1, a pressure-resistant layer 4 is arranged outside the oil pipe main body 1, an outer layer 3 is arranged outside the pressure-resistant layer 4, a connecting pipe 5 is connected to one end of the oil pipe main body 1, and the connecting pipe 5 One end is provided with an oil outlet pipe 12, an insertion mechanism is arranged between the connecting pipe 5 and the oil outlet pipe 12, a limit mechanism is arranged between both sides of the connecting pipe 5 and the oil outlet pipe 12, and a buffer mechanism is arranged in the main body of the oil pipe 1. The mechanism can buffer the liquid entering the main body 1 of the oil pipe, so as to protect the main body 1 of the oil pipe.

Embodiment 2

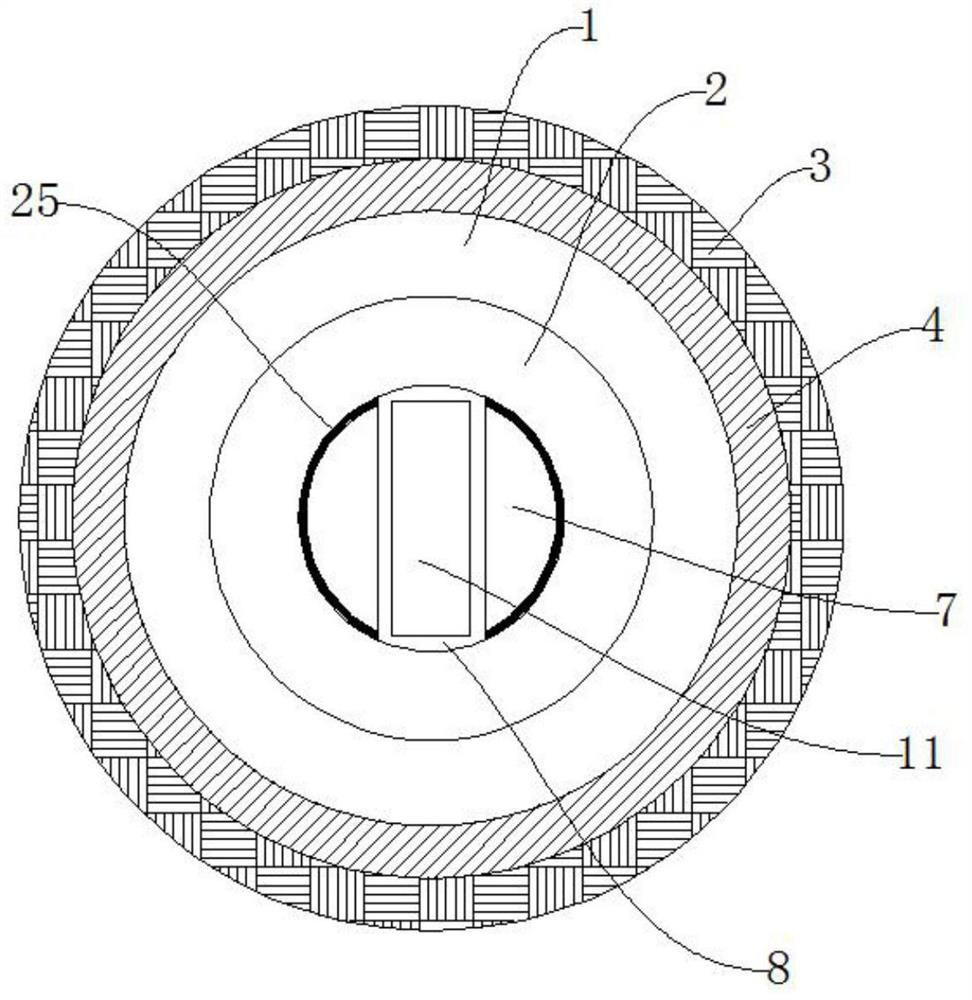

[0026] refer to Figure 6-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the pressure-resistant layer 4 includes a polyurethane layer 41 and a steel fiber layer 42, the polyurethane layer 41 is fixed on the outside of the oil pipe main body 1, and the steel fiber layer 42 is fixed on the polyurethane On the outside of layer 41, the outer layer 3 includes an aluminum-plastic composite layer 31 and a PVC layer 32, the aluminum-plastic composite layer 31 is fixed on the outside of the pressure-resistant layer 4, the PVC layer 32 is fixed on the outside of the aluminum-plastic composite layer 31, and the PVC layer 32 is sprayed with anti-corrosion coating. The paint layer 33 can increase the strength of the main body of the oil pipe through the outer layer 3 and the pressure-resistant layer 4 .

Embodiment 3

[0028] refer to figure 1 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the insertion mechanism includes an annular slot 22 and an annular flashboard 21, the annular slot 22 is set on the side wall of the oil outlet pipe 12, and the annular flashboard 21 is fixed On one side of the connecting pipe 5, the annular inserting plate 21 is inserted in the annular slot 22, and the contact between the annular inserting plate 21 and the annular slot 22 is fixed with a gasket 23, and the connecting pipe 5 and the oil outlet pipe can be increased by the sealing gasket 23. Tightness between 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com