A self-draining powder drying equipment

A technology for drying equipment and powder, applied in non-progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems of uneven drying of powder, agglomeration of metal powder, slow drying rate, etc., and reduce agglomeration and adhesion. The effect of increasing the dispersion rate and improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

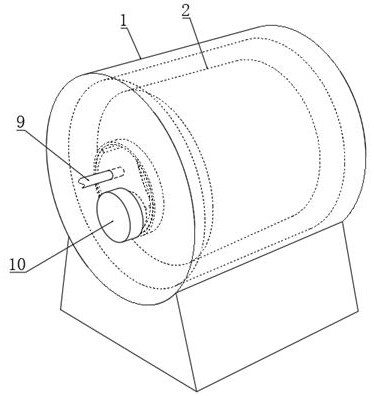

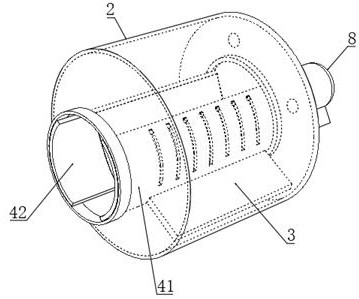

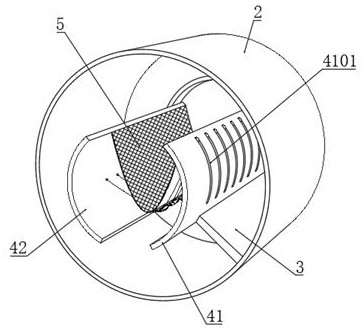

[0043] see figure 1 , a self-draining powder drying equipment, including an outer cylinder 1 fixedly connected to a base at the lower end, and an inner cylinder 2 inside the outer cylinder 1, please refer to figure 2 and image 3 , the inner side of the inner cylinder 2 is provided with a main arc plate 41 and a secondary arc plate 42 which are symmetrical to each other and have the same diameter as the inner ring. 41 and the secondary arc plate 42 are fixedly connected with micro-elastic net bag 5.

[0044] see figure 1 and figure 2 , the inner wall of the inner cylinder 2 is fixedly connected with a pusher plate 3, the right end of the outer cylinder 1 is fixedly connected with a motor 8, the output end of the motor 8 runs through the outer cylinder 1 and is fixedly connected with the right end of the inner cylinder 2, the left inner wall of the outer cylinder 1 There is a circular groove, the left end of the inner cylinder 2 is rotatably connected to the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com