Low-permeability oil reservoir bio-based microemulsion plug removal and augmented injection system and injection process thereof

A bio-based, microemulsion technology, applied in drilling compositions, wellbore/well components, chemical instruments and methods, etc., can solve the problems of poor salt resistance of anions, use restrictions, environmental pollution, etc., and achieve economical Considerable, reduce injection pressure, improve the effect of dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The present invention has a low-permeability oil reservoir bio-based microemulsion plug-removing and increasing injection system, which is made of the following components: bio-based surfactant is 0.5%, NaCl is 0.8%; kerosene is 1%; butanol is 0.5% %; the balance is water. Among them, the bio-based surfactant is made of a bio-based surfactant and a lipopeptide surfactant in a ratio of 2:1, and the bio-based surfactant is N,N-diacetic acid-N'-phenyl ten Octacyl-ethylenediamine.

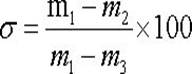

[0017] According to the above bio-based microemulsion system, the oil washing efficiency was experimentally determined. The blank sample was the injected water of an oil production plant. Three groups of parallel samples were used in the experiment. The same concentration of bio-based microemulsion water wells were selected to remove plugging and increase injection water, and take 20 g of heavy oil crude oil. Samples (at 60 °C, viscosity 10700 mPa·s) were tested. The crude oil in this low-perme...

Embodiment 2

[0032] The present invention has a low-permeability oil reservoir bio-based microemulsion plug-removing and increasing injection system, which is made of the following components: bio-based surfactant is 2%, NaCl is 1%; kerosene is 1.5%; butanol is 2% %; the balance is water. Among them, the bio-based surfactant is made of a bio-based surfactant and a lipopeptide surfactant in a ratio of 2:1, and the bio-based surfactant is N,N-diacetic acid-N'-phenyl ten Octacyl-ethylenediamine.

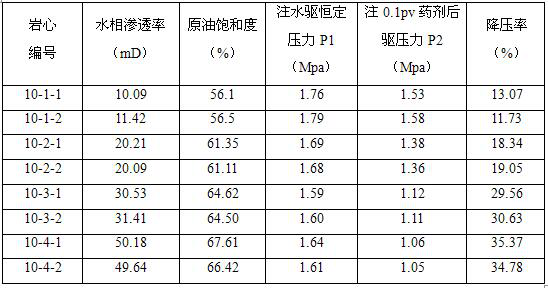

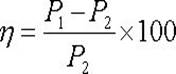

[0033] The device used in the flooding experiment is a conventional core flooding experimental device. The purpose of the experiment is to study the flow characteristics of the injected water in the core before and after treatment with the depressurization and boosting agent. The change of water phase permeability of core samples was analyzed to analyze the effect of depressurization and injection system. Table 2 shows the test results of the depressurization rate after the core was injected into ...

Embodiment 3

[0043] This embodiment provides a microemulsion plug removal and injection enhancement system suitable for low permeability oil reservoirs, which is composed of the following weight percentages:

[0044] The bio-based surfactant is 3%, the ratio of bio-based surfactant and lipopeptide surfactant is 2:1, and the bio-based surfactant is N,N-diacetic acid-N'-phenyloctadecane Acid acyl-ethylenediamine;

[0045] NaCl is 1.0%;

[0046] 2% for kerosene;

[0047] Butanol 2%;

[0048] The remainder is water.

[0049] Basic conditions of the test area:

[0050] A low permeability water well 10C94-FS104 in Daqing, the water phase permeability is 10-50mD, the reservoir temperature is 54℃, and the injection volume is 25m 3 ; Before injection, the pump pressure is 15.7Mpa, the oil pressure is 14.2Mpa, the casing pressure is 14.2Mpa, and the actual daily water injection is 2m 3 ;

[0051] Table 3 Feedback of field data from water injection wells

[0052]

[0053] The 10C94-FS104 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com