An automatic forming device for polyurethane-lined pipes

An automatic forming, polyurethane technology, applied in the direction of tubular items, household appliances, other household appliances, etc., can solve the problems of difficulty in continuing to move, the steel rope is not tightened, and the anti-eccentric bracket is loosened, so as to achieve the effect of increasing the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

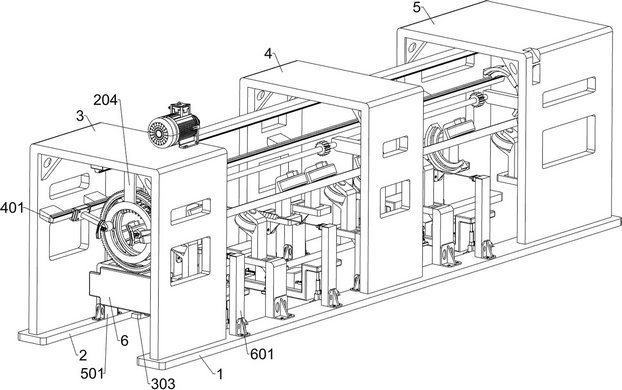

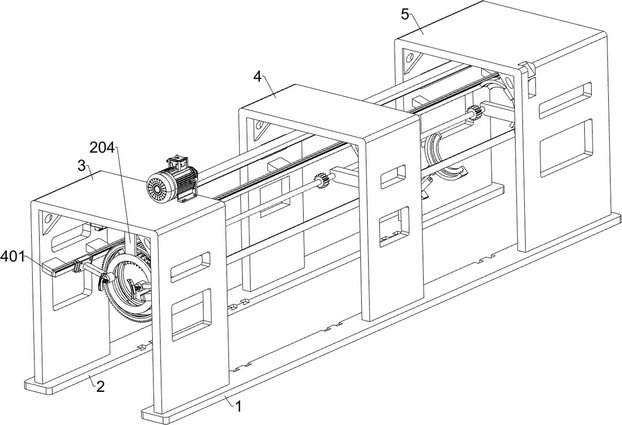

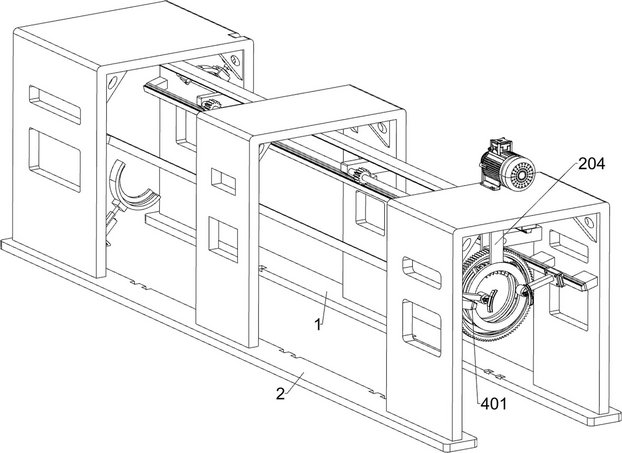

[0036] An automatic forming device for polyurethane-lined pipes, such as Figure 1-3 and Figure 9 As shown, it includes a first support plate 1, a second support plate 2, a first protective cover 3, a second protective cover 4, a third protective cover 5, a baffle plate 6, an equal division unit, a lifting unit and a carrying unit; A first protective cover 3 is welded to the front part of the upper surface of the first support plate 1 and the upper surface front of the second support plate 2; the second protective cover 4 is welded to the middle part of the upper surface of the first support plate 1 and the middle part of the upper surface of the second support plate 2 The rear part of the upper surface of the first support plate 1 and the rear part of the upper surface of the second support plate 2 are welded with a third protective cover 5; the lower part between the inner left wall and the inner right wall of the first protective cover 3 is welded with a baffle plate 6; A...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 4-13 As shown, the equal division unit includes a first electric slider 201, a first electric slide rail 202, a first horizontal plate 203, a fixed plate 204, a circular guide rail 205, a gear ring 206, a dial assembly 207, an auxiliary plate 208, Push plate 209, fixed ring 2010, first fixed block 2011, driver 2012, first transmission wheel 2013, second transmission wheel 2014, first spur gear 2015, transmission shaft 2016, second spur gear 2017, third spur gear 2018 , the third bracket 2019, the second bracket 2020 and the first bracket 2021; the middle part of the lower surface of the first protective cover 3 is welded with the first transverse plate 203; the middle part of the lower surface of the second protective cover 4 and the middle part of the lower surface of the third protective cover 5 are both Welded with the first horizontal plate 203; the lower surface of the first horizontal plate 203 is bolted to the first elec...

Embodiment 3

[0047] On the basis of Example 2, such as figure 1 with Figure 15-16 As shown, a pulling unit is also included, the inner wall of the first protective cover 3 is connected with the pulling unit; the inner wall of the second protective cover 4 is connected with the pulling unit; the inner wall of the third protective cover 5 is connected with the pulling unit; the pulling unit Including a second electric slide rail 401, a second electric slider 402, a second connecting rod 403 and a third electric clamper 404; each bolt on the upper part of the inner left wall and the upper part of the inner right wall of the first protective cover 3 is connected with a first Two electric slide rails 401; The left wall top and the inner right wall top in the second protective cover 4 are respectively connected with a second electric slide rail 401 bolts; The two electric slide rails 401 are connected by bolts; each of the two second electric slide rails 401 is slidably connected with a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com