Pollution-free preparation process of direct blue 281 dye

A preparation process, pollution-free technology, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of increasing product costs, environmental pollution, etc., and achieve the effects of increasing production capacity, reducing production costs, and improving dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In conjunction with the following embodiments, the following embodiments are illustrative and not restrictive. The following embodiments cannot be used to limit the protection scope of the present invention.

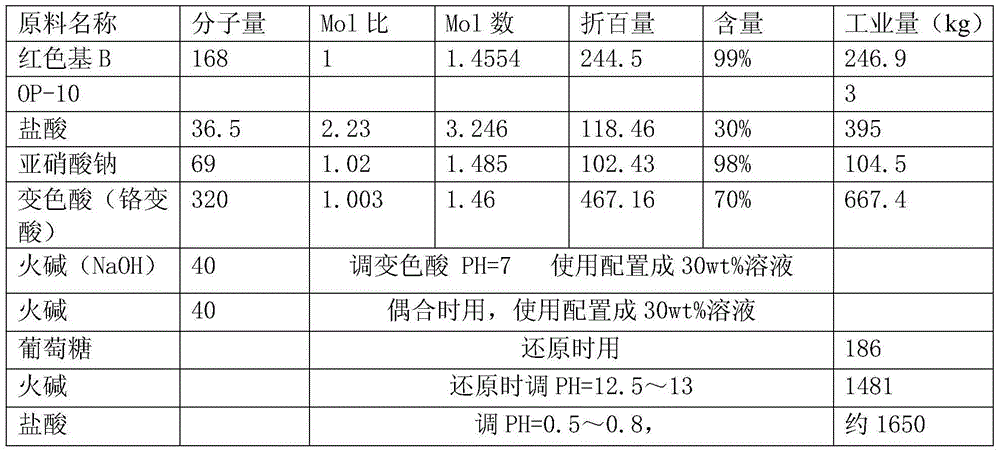

[0028] The raw materials are as follows:

[0029]

[0030] A pollution-free preparation process of direct blue 281 dye, the steps are as follows:

[0031] ⑴ Diazotization of red base B (p-nitro o-methoxyaniline)

[0032] Put 1000L of water in the diazotizer, add red base B and OP-10, beat for 2 hours, add ice to cool to 0-10℃, then add a certain amount of hydrochloric acid, keep the temperature at 8-10℃, add 30wt after 40 minutes % Sodium nitrite solution, control the end point, stir for 1 to 2 hours, the solution is clarified, the solution temperature t=5~8℃, then use 150kg sodium acetate to adjust pH=3~3.5, total volume V=2000L or so, waiting for coupling;

[0033] ⑵Coupling

[0034] Put water (2500L) in the coupling pot, add chromotropic acid (1,8-dihydroxynaphthalene-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com