Automatic detonating bomb filling system and control method thereof

A technology for automatic filling and detonation of bombs, which can be used in blasting and other directions to solve problems such as low efficiency, low efficiency of manual charging, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

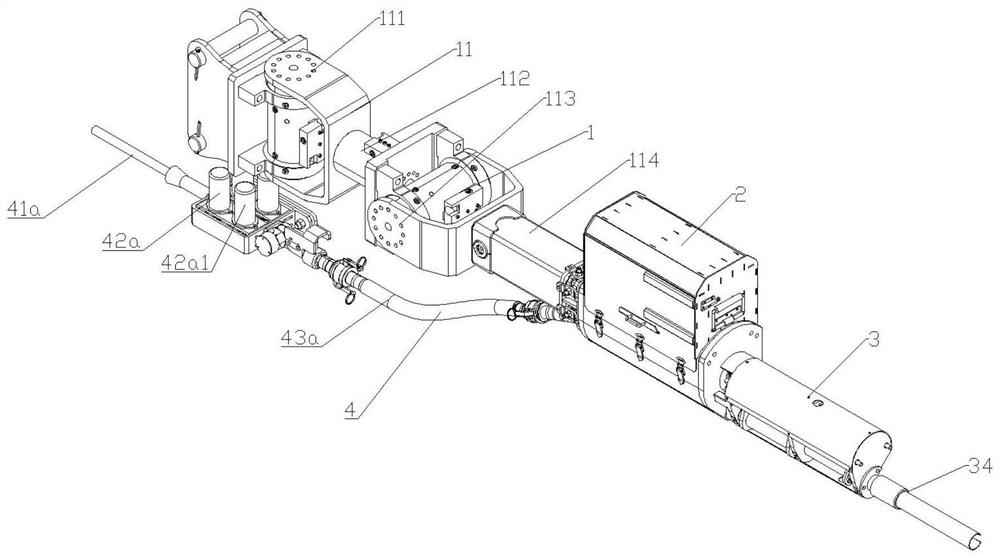

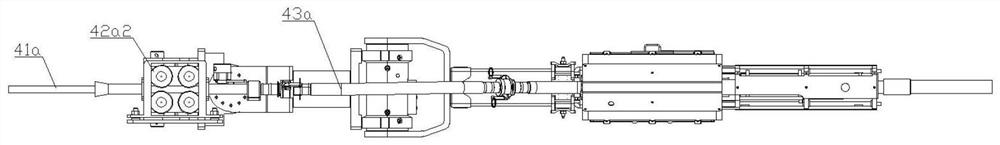

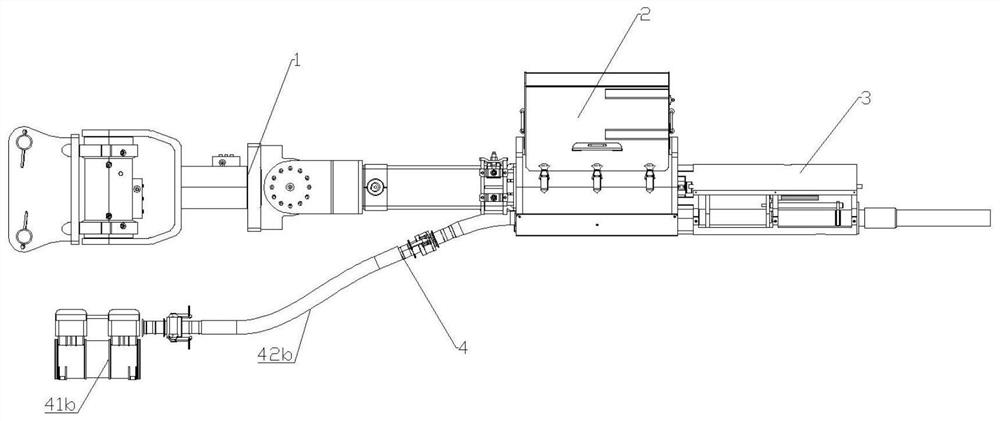

[0066] refer to Figure 1-Figure 13 , the present invention provides a detonating bomb automatic filling system, comprising:

[0067] The gunhole finding device 1 includes a multi-degree-of-freedom boom system 11 and a vision system for finding and positioning blastholes. Specifically, in some embodiments, the vision system is arranged on the multi-degree-of-freedom boom system 11 , through the continuous attitude adjustment of the multi-degree-of-freedom arm support system 11, the photos within the position range of the blast hole are taken in all directions, and then the target blast hole is found through internal analysis and processing; in some embodiments, the vision system is set in the same position as The multi-degree-of-freedom boom system 11 is connected to the device at the end, and through the continuous adjustment of the attitude of the multi-degree-of-freedom boom system 11, the photos within the range of the gun hole position are taken in all directions, and the...

Embodiment 2

[0085] The present invention also provides a control method for the automatic filling system of detonating bombs, the steps of which include:

[0086] S1: Fill the magazine 22 of the automatic blanking device 2 with the detonating bomb assembly 5, and then start the detonating bomb automatic filling system;

[0087] S2: Under the action of the control system and the vision system, the multi-degree-of-freedom boom system 11 continuously adjusts the posture until the target gun hole is located, and the vision system feeds back the finding result to the control system;

[0088] S3: The control system that receives the target blast hole information controls the action of the blanking roller 21 of the automatic blanking device 2, and receives the detonating bomb assembly 5 in the magazine 22 of the automatic blanking device 2 to the capacity of the blanking roller 21. Put it in the groove 211, and control the blanking roller 21 to carry the detonating bomb assembly 5 to rotate to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com