Automatic height measuring and leveling mechanism for battery swap station vehicle

A technology of vehicle automation and leveling mechanism, applied in charging stations, electric vehicles, vehicle energy storage, etc., can solve the problems of wasting time and reducing work efficiency, and achieve the effect of saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

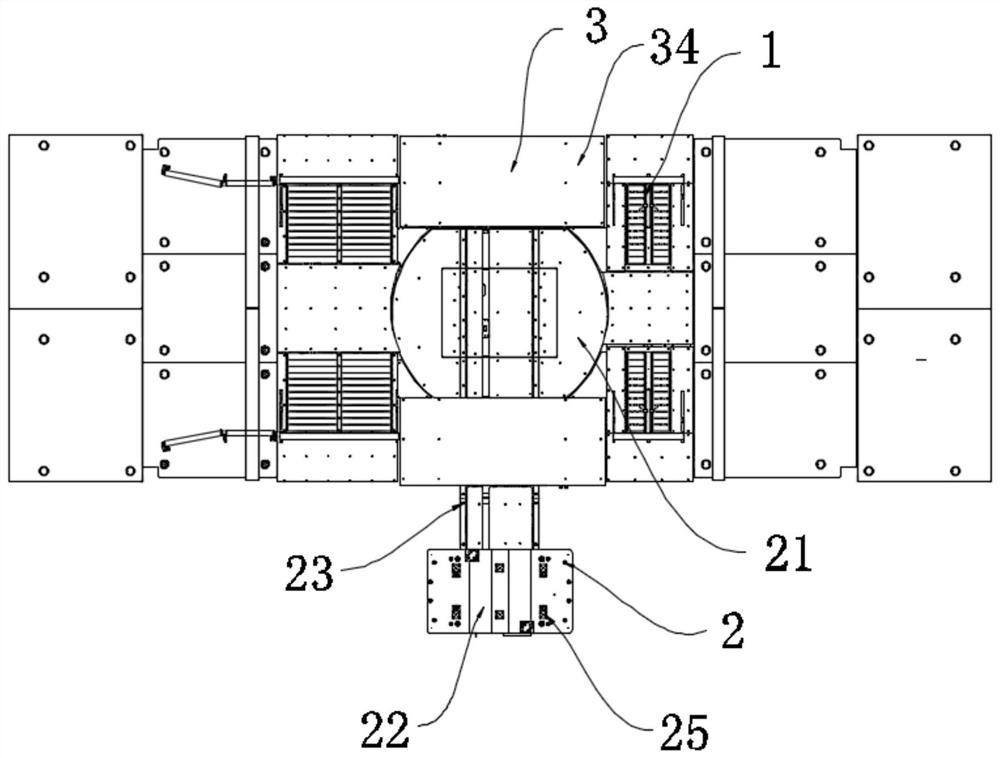

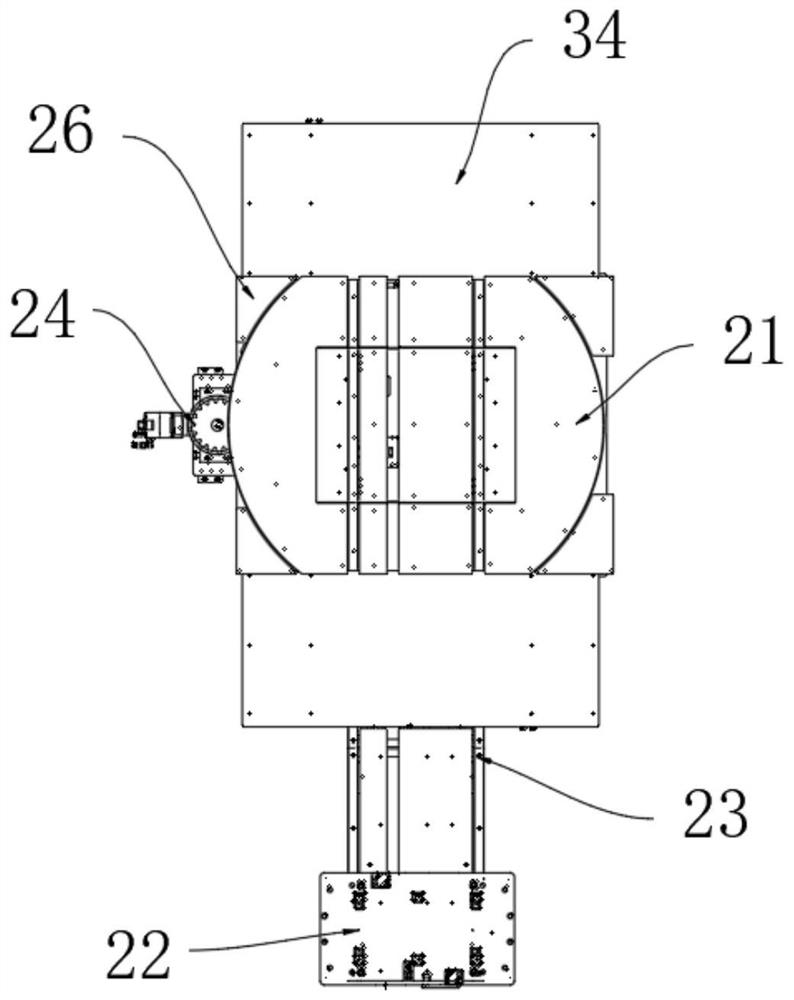

[0033] see Figure 1-6 , the present invention provides a technical solution: an automatic height-measuring and leveling mechanism for vehicles in a power station, including a leveling assembly 1 and an altitude-measuring assembly 2;

[0034] Four leveling assemblies 1 are arranged on both sides of the height measuring assembly 2;

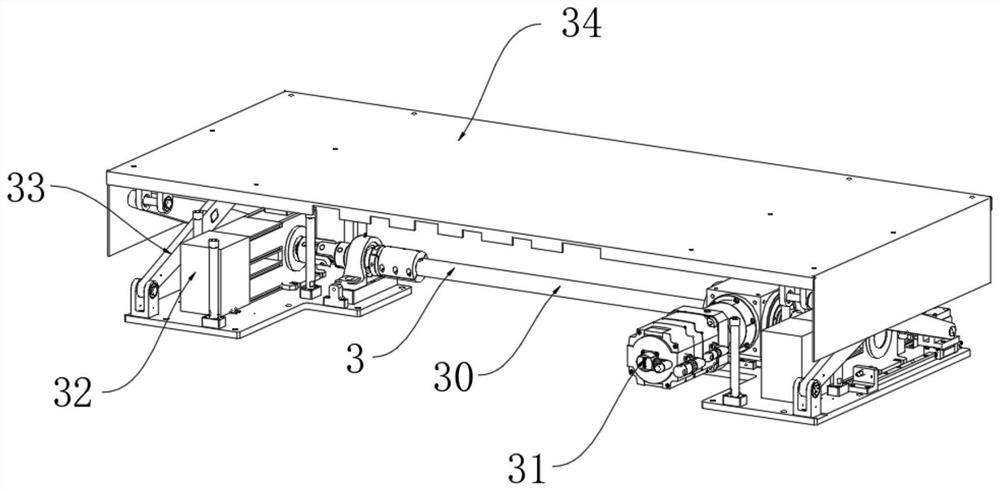

[0035] Two jacking assemblies 3 are provided on the other two sides of the height measuring assembly 2;

[0036] The four leveling assemblies 1 all include a first base plate 10, a lead screw 11, a first motor 12, a bevel block 13, a first scissor arm 14, a second connecting rod 141, a roller 142, a threaded sleeve 15, and a push wheel plate 16. Slide plate 17, connecting plate 171, first connecting rod 18, top plate 19 and through groove 191;

[0037] A top plate 19 is provided directly above the first bottom plate 10, and two through grooves 191 are symmetrically opened on both sides of the upper surface of the top plate 19;

[0038] The cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com