Reflectivity adjusting structure, manufacturing method and display panel

A technology for adjusting structure and reflectivity, applied in optical components, optics, instruments, etc., can solve the problems of high objective conditions and poor compatibility of asymmetric transmission devices, and achieve insensitive design structure polarization, low design condition requirements, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

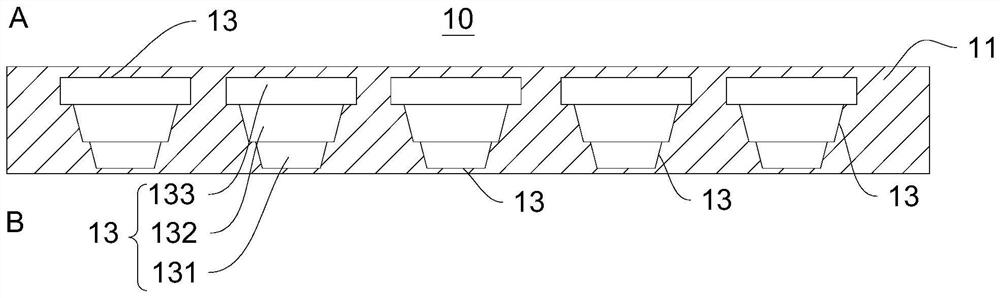

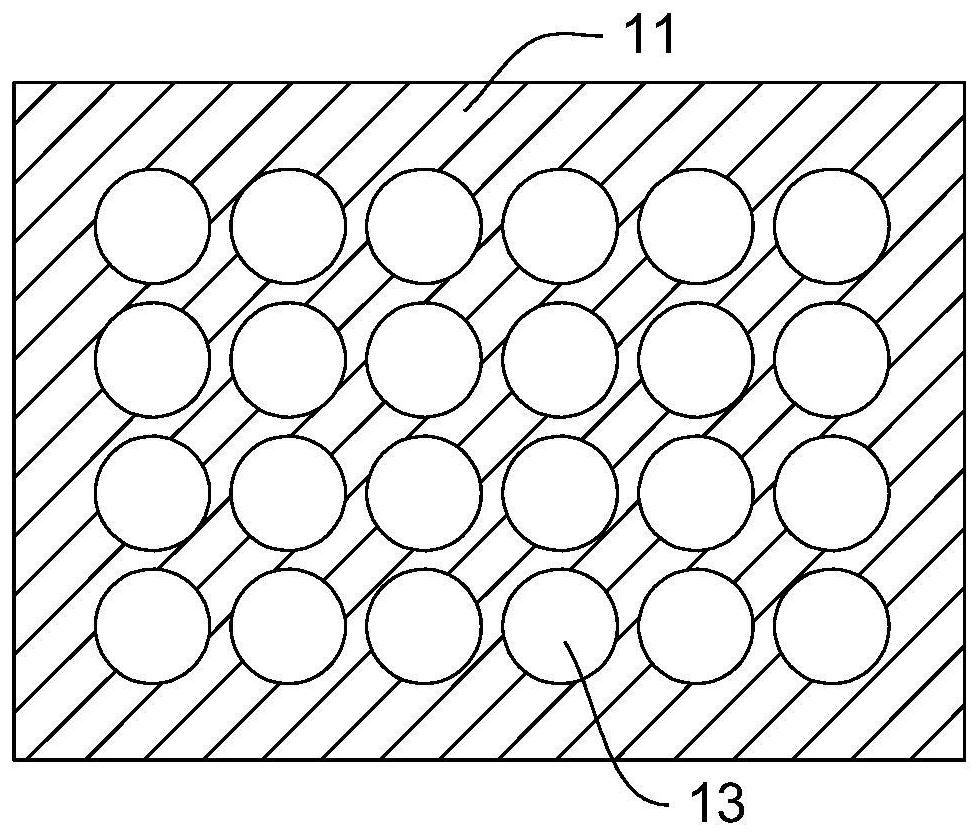

[0069] Example 1: By setting the metal layer 131 radius r1=100nm, the dielectric layer 132 radius r2=150nm, the metal layer 131 thickness h1=125nm, the dielectric layer 132 thickness h2=550nm, the metal material is Al, and the base layer 133 radius r3=250nm , the dielectric layer 132 is made of SiN x , the refractive index of the dielectric layer 132 is 2.02, and the material of the base layer 133 is Al 2 o 3 , the refractive index of the base layer 133 is 1.76, and the refractive index of the embedded elastic medium layer 11 is 1.52. The embedded unit 13 is designed to change the gap to two situations of 600nm and 1.1um.

[0070] Based on the above example conditions, for the user end, usually the elastic medium layer 11 is not deformed, and when the gap between the embedded units 13 is 600 nm, the reflectance of the reflectance adjusting structure 10 on the display panel 20 in the visible light band can reach 70% stably, Can be used as a reflector with high reflectivity, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com