Method and system for predicting fatigue life of sucker rod

A fatigue life prediction and fatigue life technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unreasonable, damage, failure probability value greater than zero, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

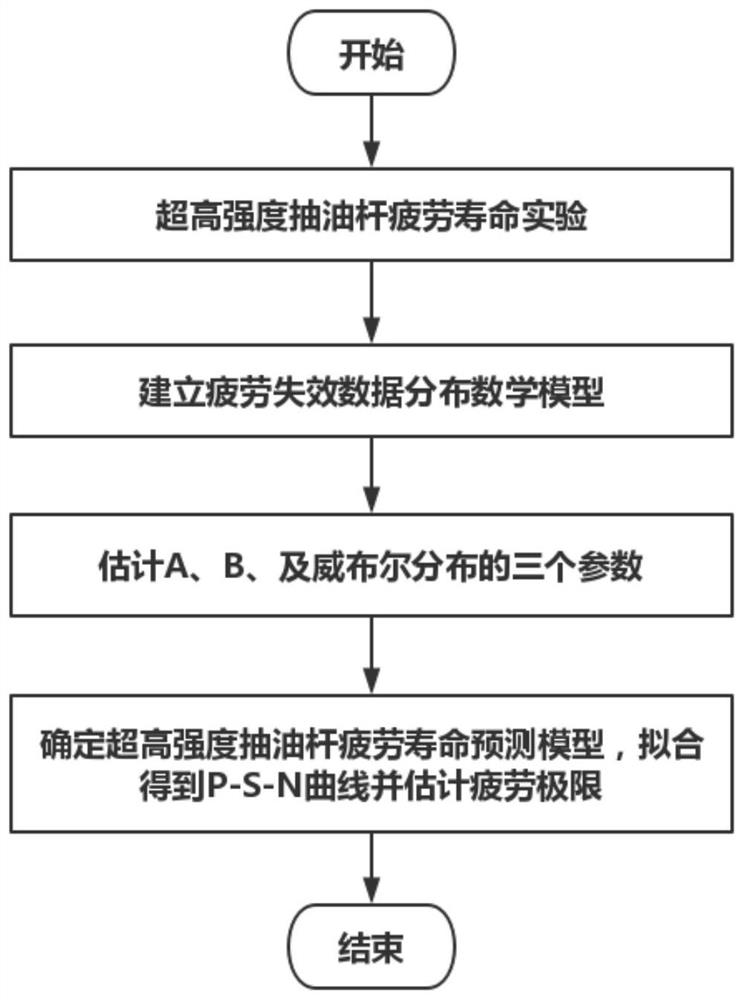

Method used

Image

Examples

Embodiment 1

[0106] According to the "SY / T 5029-2013 Sucker Rod" steel sucker rod fatigue performance requirements, the fatigue life test of ultra-high strength sucker rods is carried out, and the experiment is divided into 3 groups of stress levels, and each group is tested with 5 specimens, and the fatigue is recorded The experimental data are shown in Table 1.

[0107] HL type sucker rod fatigue test data

[0108]

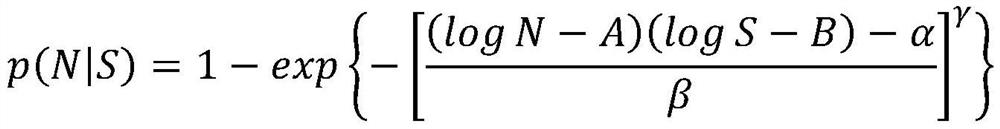

[0109] According to the obtained experimental data, the model parameters proposed in step 2 are estimated, and the parameters A, B and Weibull distribution three parameters α, β, γ are estimated according to the method of steps 3 and 4. The results are shown in the following table:

[0110]

[0111]

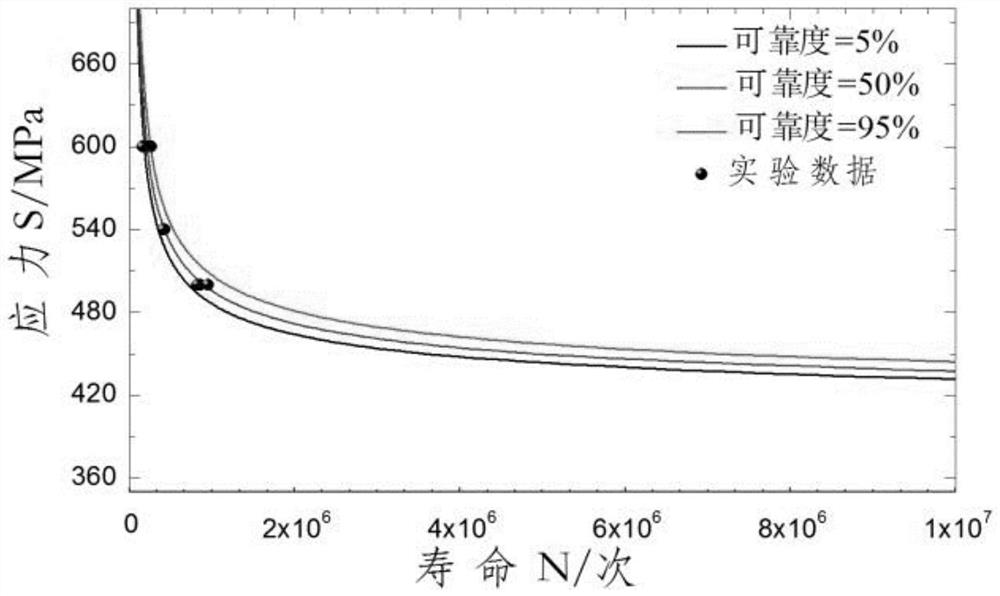

[0112] refer to figure 2 , to estimate the fatigue limit: From the fitted P-S-N curve, it can be found that the lower part of the curve slowly approaches the fatigue limit. When N tends to infinity, the calculated fatigue limit value is: 327.49MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com