A kind of preparation method of soft magnetic alloy bar

A technology of soft magnetic alloys and rods, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of limited application range, poor processing performance, and expensive price, and achieve low preparation cost and magnetic The effect of stability and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

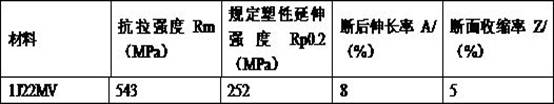

Examples

preparation example Construction

[0044] A method for preparing a high-strength soft magnetic alloy rod, comprising the following operations:

[0045] 1) Vacuum melting:

[0046] Prepare raw materials according to the smelting requirements of soft magnetic alloy 1J22MV, in terms of mass percentage, including C≤0.04%, Si≤0.30%, Mn≤0.30%, P≤0.020%, S≤0.020%, Cu≤0.20%, Ni≤0.50 %, Co is 48.0~51.0%, V is 1.50~2.10%, Mo is 0.1~0.2%, and Fe is the balance;

[0047] Put the pure iron, cobalt sheet, vanadium iron and molybdenum strips in the raw material into the intermediate frequency vacuum induction furnace for smelting;

[0048] Vacuumize the vacuum induction furnace to ≤133Pa after closing the furnace, power on with low power (50~70kw) for preheating; when the vacuum degree is ≤0.66Pa, increase the power (120~160kw) to quickly chemicalize the material, and the splashing during the materialization process occurs in time Reduce the power (80~100kw); Chemical time: 1.5~2 hours;

[0049] After the material is heate...

Embodiment 1

[0076] A method for preparing a high-strength soft magnetic alloy rod, comprising the following operations:

[0077] 1) Vacuum melting:

[0078] According to the requirements of smelting, weigh the raw materials according to the requirements, in terms of mass percentage, including C≤0.04%, Si≤0.30%, Mn≤0.30%, P≤0.020%, S≤0.020%, Cu≤0.20%, Ni ≤0.50%, Co is 48.5~50.0%, V is 1.90~2.10%, Mo is 0.1~0.15%, Fe is the balance;

[0079] In the weighed raw materials, first put the pure iron into the bottom of the crucible and put it in a flat layer, and put the rest of the pure iron into the surrounding and upper middle of the crucible; then put the Co sheet into the upper middle of the crucible; finally put the high-vanadium iron and Mo The upper part of the crucible; put it into an intermediate frequency vacuum induction furnace for melting;

[0080] After the furnace is vacuumed ≤ 133Pa, low power (50~70kw) power supply is used for preheating. When the vacuum degree is ≤ 0.66Pa, th...

Embodiment 2

[0101] A method for preparing a high-strength soft magnetic alloy rod, comprising the following operations:

[0102] 1) Vacuum melting:

[0103] According to the requirements of smelting, weigh the raw materials according to the requirements, in terms of mass percentage, including C≤0.04%, Si≤0.30%, Mn≤0.30%, P≤0.020%, S≤0.020%, Cu≤0.20%, Ni ≤0.50%, Co is 50.0~51.0%, V is 2.00~2.10%, Mo is 0.15~0.2%, Fe is the balance;

[0104] In the weighed raw materials, first put the pure iron into the bottom of the crucible and put it in a flat layer, and put the rest of the pure iron into the surrounding and upper middle of the crucible; then put the Co sheet into the upper middle of the crucible; finally put the high-vanadium iron and Mo The upper part of the crucible; put it into an intermediate frequency vacuum induction furnace for melting;

[0105] After the furnace is vacuumed ≤ 133Pa, low power (50kw) power supply is used for preheating, when the vacuum degree is ≤ 0.66Pa, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com