Optical machine definition adjusting and testing method and system

A high-definition, optical-mechanical technology, applied in television, electrical components, image communication, etc., can solve the problems of low efficiency, high defect leakage rate, and manpower-dependent commissioning methods, and achieve the requirements of improving commissioning efficiency and reducing manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical solutions of the embodiments of the present invention or in the prior art, specific embodiments of the present invention will be described below with reference to the drawings. It will be apparent that the drawings in the following description are merely some embodiments of the present invention, and those of ordinary skill in the art can also obtain other drawings according to these drawings without paying creative labor, and obtained Other embodiments.

[0031] In order to make the drawing, only the parts associated with the present invention are schematically shown, which do not represent the actual structure of the product. In addition, it is schematically drawn one of the same structures or functions in some figures, and only one of them is schematically drawn, or only one of them is schematically drawn. In this article, "one" not only means "only one", but also "more than one" situation.

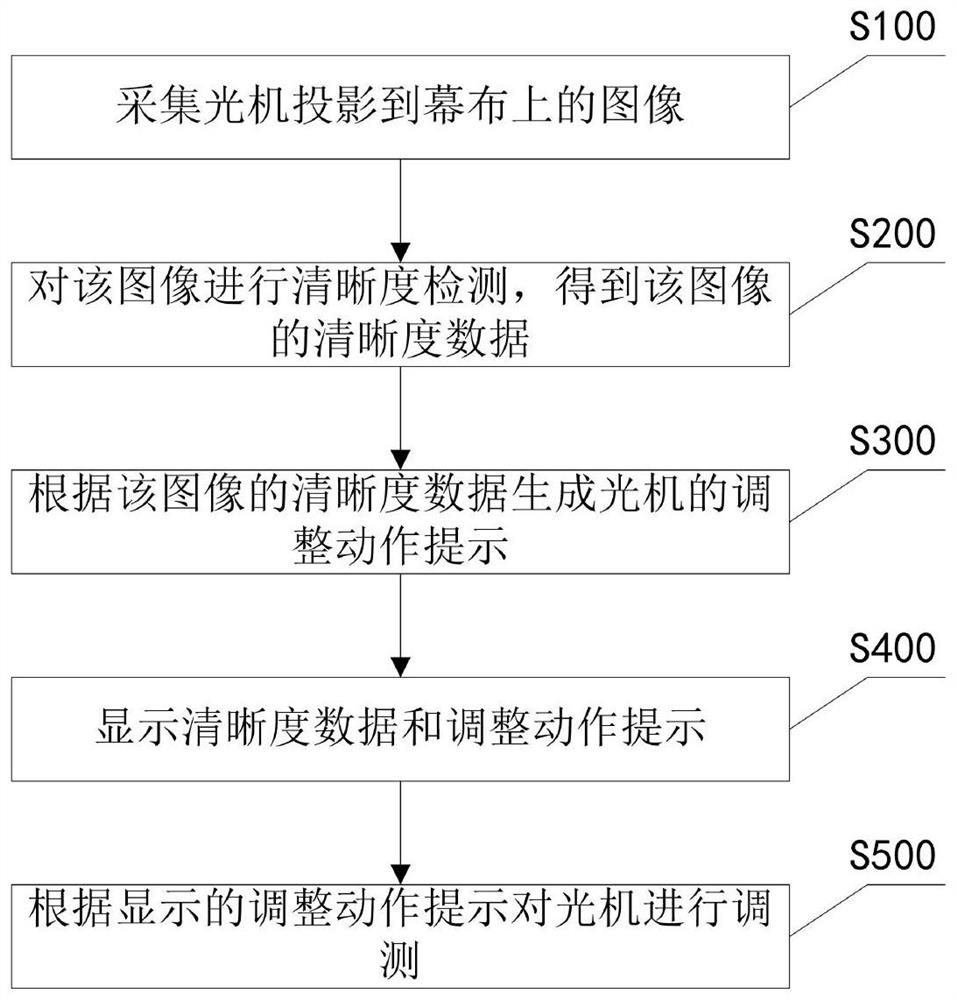

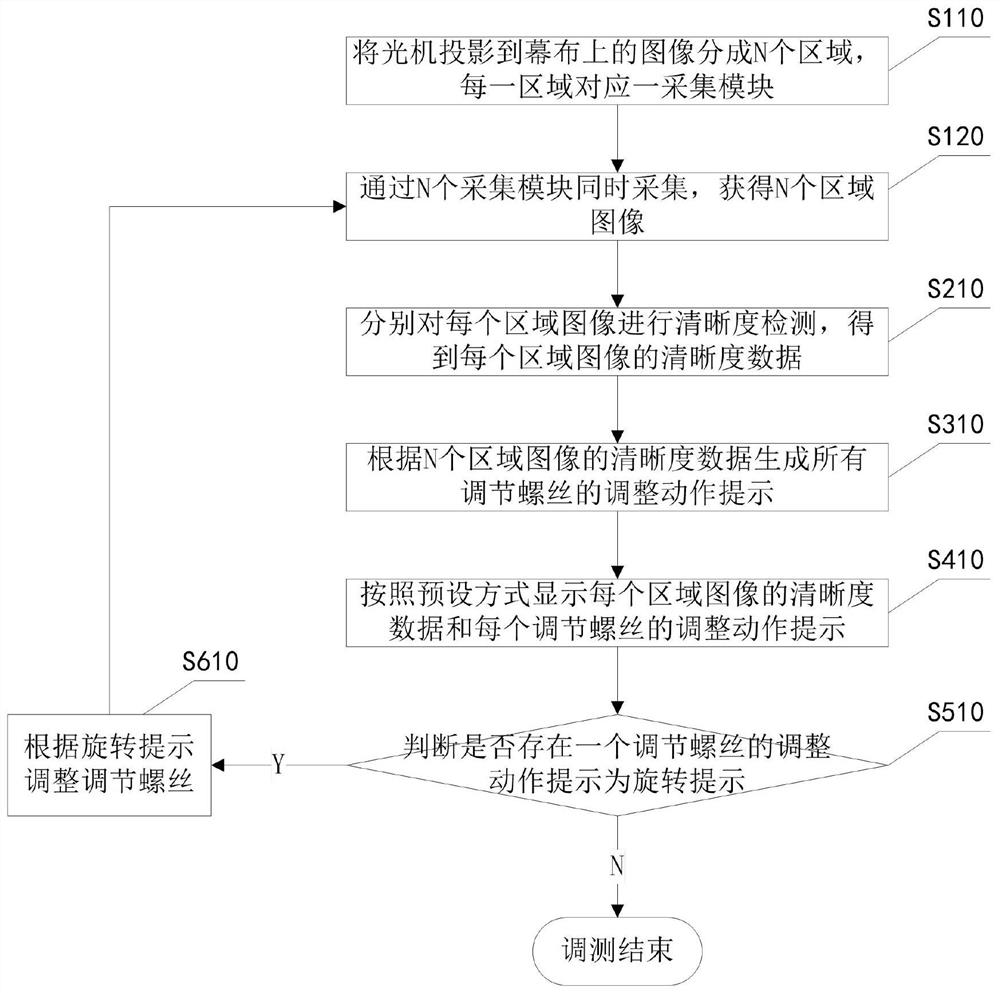

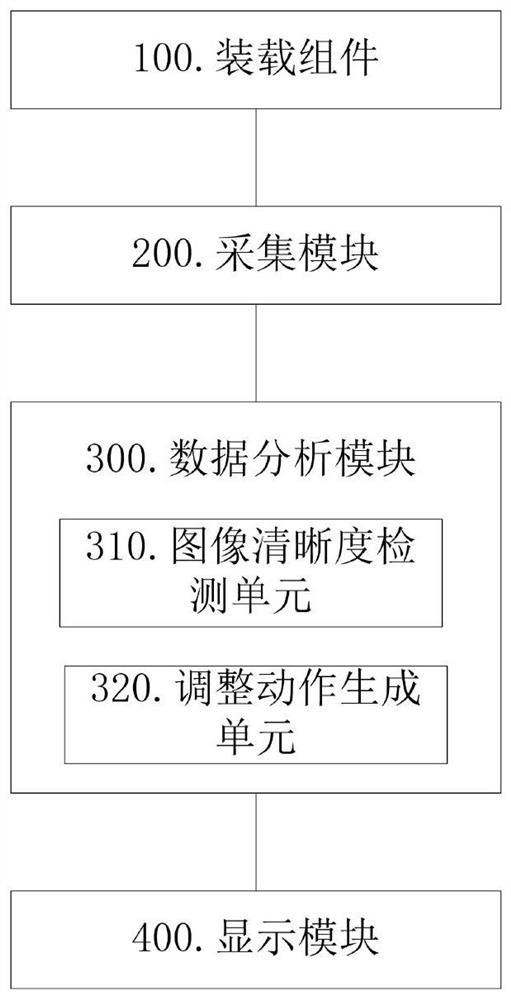

[0032] An embodiment of the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com