A cleaning device for automatic production of computer case shell production

A technology for a case shell and a cleaning device, which is applied to the cleaning method using tools, the cleaning method using liquid, the cleaning method and the utensils, etc., can solve the problems of poor use effect, pollution of the casing, dripping, etc. The effect of avoiding the exposure of the hose and the leakage of the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

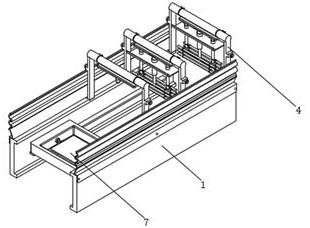

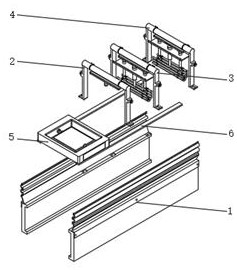

[0030] Such as figure 1 , 2 , 3, 7, and 8, a computer case shell production cleaning device for automatic production, including a waterproof support 1 and a chain 6, the waterproof support 1 includes a side frame 101, and the side frame 101 is provided with a chain 6 , the waterproof support 1 also includes a groove 102, the upper end of the side frame 101 is provided with a plurality of grooves 102, the upper ends of the two chains 6 are connected with a mobile placement platform 5, and the mobile placement platform 5 is placed with the shell 7 to be cleaned, and the side frame The groove 102 on one side of the upper end of the 101 is provided with a water spray support structure 2, the groove 102 is provided in the middle of the upper end of the side frame 101 and the first cleaning structure 3 is provided, and the groove 102 on the other side of the upper end of the side frame 101 is provided with the first cleaning structure 3. Two cleaning structures 4, the structure of ...

Embodiment 2

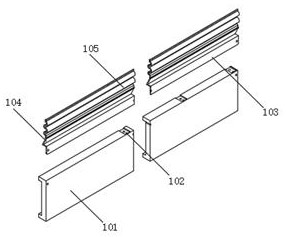

[0033] Such as image 3 As shown, another waterproof bracket for automatic production of the cleaning device for computer case shell production, the waterproof bracket 1 also includes a connecting strip 103, an L-shaped sealing strip 104 and a bending strip 105, and the upper part of the side wall of the side frame 101 A connecting strip 103 is provided, the upper end of the connecting strip 103 is provided with an L-shaped sealing strip 104, the upper end of the L-shaped sealing strip 104 is provided with a bending strip 105, and the sealing between the L-shaped sealing strip 104 and the side frame 101 is arranged, and the L-shaped sealing The strip 104 is placed on the upper end of the side frame 101. Due to the sealing arrangement between the L-shaped sealing strip 104 and the side frame 101, sewage is prevented from flowing out from the gap between the side frame 101 and the L-shaped sealing strip 104. After the top of the bending strip 105 is bent , can effectively preven...

Embodiment 3

[0035] Such as figure 2 , 4 Shown, a kind of automatic production of the mobile placement platform of the cleaning device for computer case shell production, the mobile placement platform 5 includes a platform body 501, a through groove 502, a placement hole 503, a first linear driver 504, a first sealing cover 505, The second linear driver 506 and the second sealing cover 507, the upper end of the chain 6 is equipped with a platform body 501, the upper end of the platform body 501 is provided with a through groove 502, the two sides of the platform body 501 are provided with placement holes 503, and the platform body 501 is placed on one side. A first linear driver 504 is inserted and connected to the hole 503, a first sealing cover 505 is installed at the opening of the hole 503 on one side of the table body 501, and a second linear driver 506 is inserted and connected to the hole 503 on the other side of the table body 501. A second sealing cover 507 is installed at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com