V-shaped anvil for drawing out large-specification round rod and method for drawing out large-specification round rod

A large-scale, round bar technology, used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve solidification defects and micro-crack expansion, unqualified flaw detection, and difficult to guarantee The quality of the final product and the qualified rate of flaw detection can solve the problem of coarse eutectic carbide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention has no special limitation on the preparation method of the electroslag ingot, and the electroslag ingot can be prepared by adopting the preparation method of the electroslag ingot well-known to those skilled in the art.

[0037] In the present invention, the composition of the electroslag ingot is preferably a ledeburite tool steel composition, more preferably a Cr12MoV composition.

[0038] The present invention has no special limitation on the specific upsetting method, and the upsetting method well-known to those skilled in the art can be used for upsetting. In the present invention, the diameter of the upset blank is preferably ≥1700mm.

[0039] In the present invention, the single-pass reduction in the elongation process is preferably 15-30%, more preferably 20-25%, and most preferably 22-23%.

[0040] In the present invention, the feeding amount in the elongating process is preferably 650-700 mm, more preferably 660-690 mm, and most preferab...

Embodiment 1

[0050] The present embodiment adopts V-type anvil to carry out the production of the Cr12MoV steel round rod that diameter is 850mm:

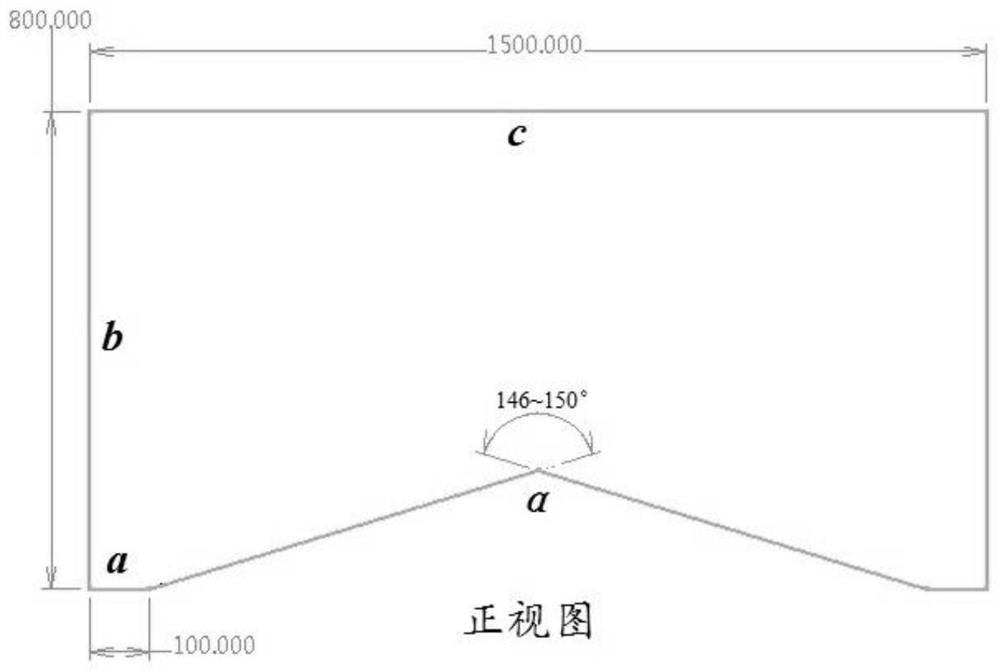

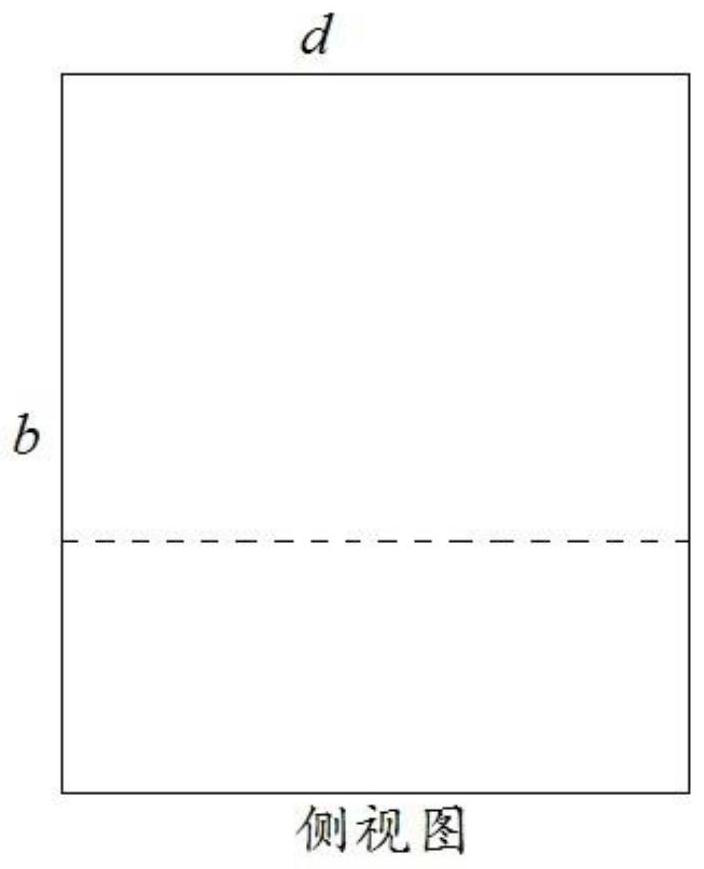

[0051] After the electroslag ingot pier is thickened, use figure 1 and figure 2 The V-shaped anvil of the structure shown is drawn, the V-shaped angle α is 150°C, the side length a is 100mm, the anvil height b is 800mm, the anvil length c is 1500mm, and the anvil width d is 800mm.

[0052] Select the above-mentioned V-shaped anvils with upper and lower symmetry for the drawing length. During the drawing process, the single-pass reduction is 27%, and the feeding amount is 680mm. The secondary reduction was 8%, and the finished product was obtained.

[0053] The finished product is spheroidized and annealed.

[0054] The main components of the Cr12MoV round rod prepared in Example 1 of the present invention are: 1.6wt% C; 12.1wt% Cr; 0.35wt% Si; 0.5wt% Mo; 0.3wt% Mn; 0.02wt% S 0.025wt% P; 0.2wt% V; balance Fe.

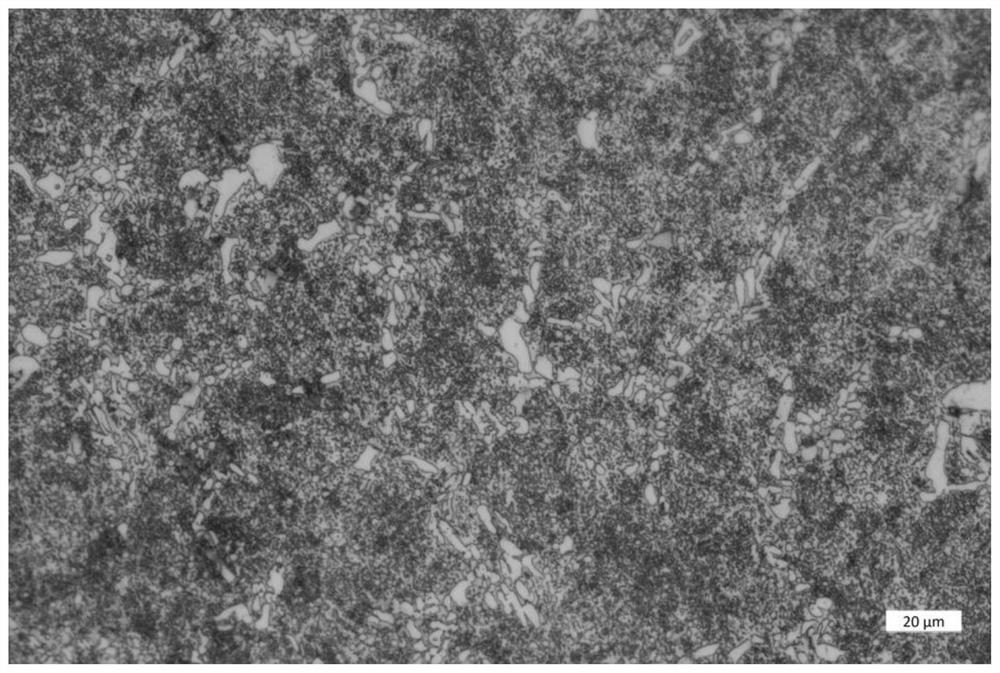

[0055] Observe the eutectic ...

Embodiment 2

[0057] The present embodiment adopts V-type anvil to carry out the production of the Cr12MoV steel round rod that diameter is 1000mm:

[0058] After the electroslag ingot pier is thickened, use figure 1 and figure 2 The V-shaped anvil of the structure shown is drawn, the V-shaped angle α is 148°C, the side length a is 100mm, the anvil height b is 800mm, the anvil length c is 1500mm, and the anvil width d is 800mm.

[0059]Select the upper and lower symmetrical V-shaped anvils for combination in the drawing length. The single-pass reduction during the drawing process is 30%, and the feeding amount is 650mm. The sub-reduction is 10%, and the finished product is obtained.

[0060] The finished product is spheroidized and annealed.

[0061] The main components of the Cr12MoV round rod prepared in Example 2 of the present invention are: 1.55wt% C; 12.5wt% Cr; 0.4wt% Si; 0.55wt% Mo; 0.4wt% Mn; 0.03wt% S 0.03 wt% P; 0.28 wt% V; balance Fe.

[0062] Observe the eutectic carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com