Tightening gun bit replacing device and tightening module

A technology for tightening guns and bits, which is applied in the direction of wrench, wrench, screwdriver, etc. It can solve the problem that the tightening module cannot adapt to various specifications of parts to be tightened, so as to improve work efficiency, save costs, and facilitate quick replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

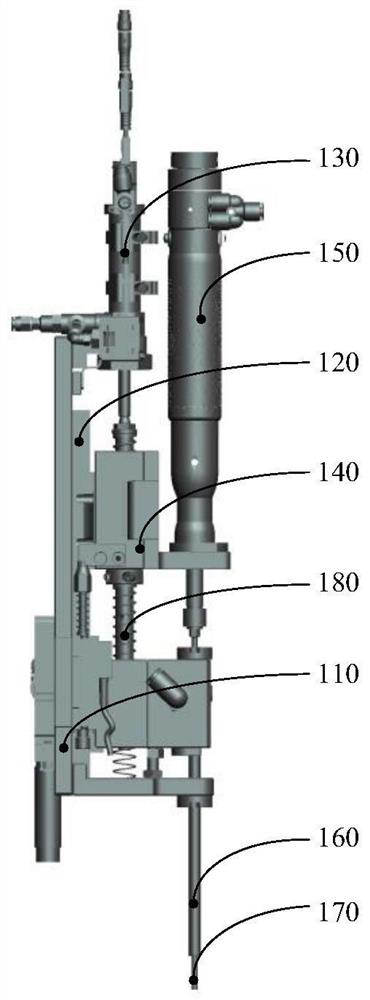

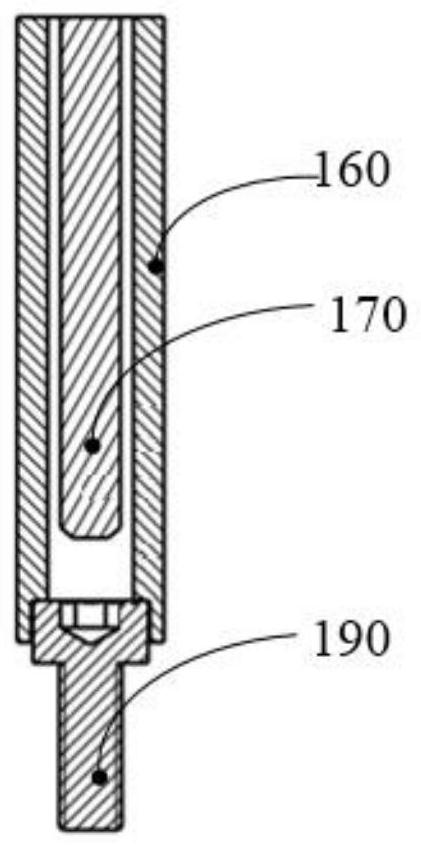

[0124] This embodiment provides a tightening bit replacement device, including a tightening execution unit, a tightening drive unit and a detachable tightening unit, wherein the tightening drive unit of the tightening bit replacement device is fixed on a tightening module The tightening execution unit is detachably connected to the tightening drive unit through the tightening detachable unit, and the tightening execution unit is adapted to the part to be tightened; when the tightening execution unit is connected to the tightening drive unit, the The tightening driving unit is used to drive the tightening execution unit to disassemble and assemble the parts to be tightened.

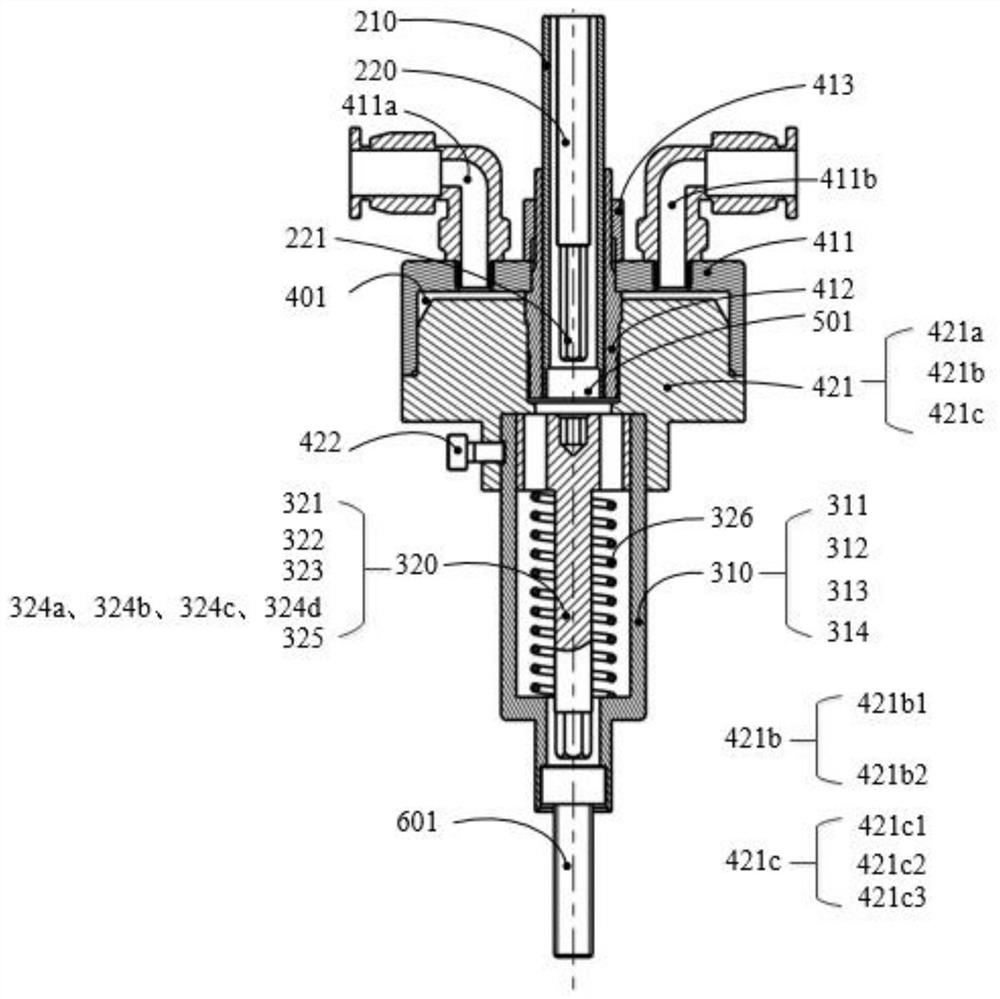

[0125] Specifically, as an exemplary implementation, see the attached image 3 to attach Figure 12 , the tightening drive unit includes a first pick-up cylinder 210 and a first batch head 220, the first batch head 220 is located in the cavity of the first pick-up cylinder 210, and one end of the first pi...

Embodiment 2

[0157] This embodiment body provides another kind of tightening gun bit replacement device, as attached Figure 13 As shown in the figure, they are schematic diagrams of the structure of two different tightening bit replacement devices provided in this embodiment. The tightening gun bit replacement device provided in this embodiment is the same as that in Embodiment 1 to realize the tightening execution unit and the tightening drive unit through vacuum force. According to different connection or separation states, the tightening gun replacement device provided in this embodiment uses magnetic attraction to complete the quick replacement of the tightening execution unit. In this embodiment, the first connection assembly includes an electromagnet 431, the first connection assembly is fixedly arranged on the outer wall of the first pickup cylinder, and the electromagnet is arranged on the first pickup cylinder for One end of the second pick-up cylinder is connected; the second co...

Embodiment 3

[0159] This embodiment provides another tightening gun bit replacement device, as shown in Figure 14 (a), which is a schematic structural diagram of the tightening gun bit replacement device provided in this embodiment, and the tightening gun bit replacement provided by this embodiment The device is different from the connection or separation relationship between the tightening execution unit and the tightening drive unit realized by vacuum force in Embodiment 1. The tightening gun replacement device provided in this embodiment uses the spring plunger scheme to complete the fast replacement of the tightening execution unit. In this embodiment, the first connection assembly includes a first spring plunger connector 451 and at least one first spring plunger hole 451a, and the first spring plunger hole 451a is arranged on the first spring plunger On the connecting piece 451 ; the first spring plunger connecting piece 451 is fixedly disposed on the outer periphery of the first pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com