A connection component for prefabricated steel structure

A technology for connecting components and steel structures, applied in building construction, architecture, photovoltaic power generation, etc., can solve the problems of slow installation, taking up more space for carrying, affecting safety, etc., to increase load-bearing capacity, ensure safety performance, guarantee The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

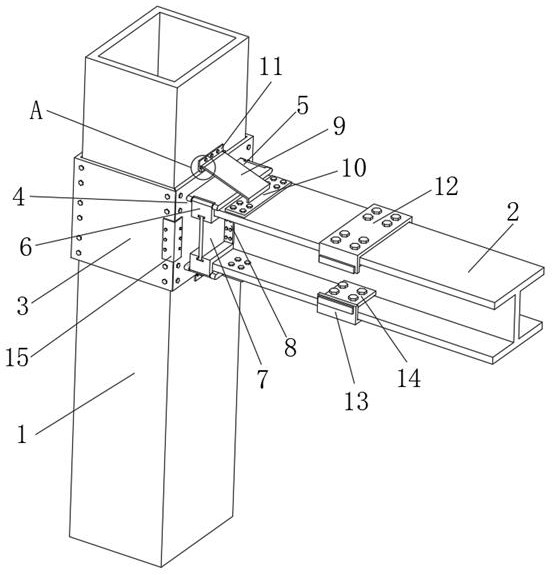

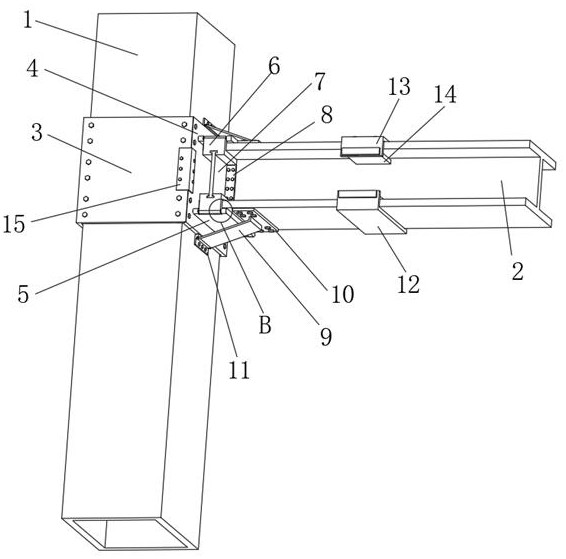

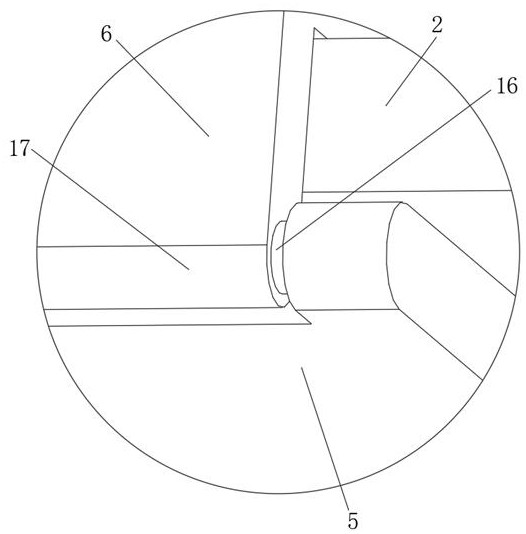

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a connecting assembly for an assembled steel structure, comprising a strut 1, one end of the strut 1 is provided with a beam 2, and a detachable connecting assembly 3 is provided near the upper end of the strut 1, and the strut 1 1 is also provided with a connecting component 2 4 which is combined with the connecting component 1 3, and one end of the connecting component 2 4 is fixedly connected with a fixing plate 5 for convenient installation of the beam 2, and both ends of the fixing plate 5 are provided with A hook plate 6 for clamping and maintaining stability at both ends of the beam 2, one end of the hook plate 6 is provided with a support plate 7 for supporting the beam 2, and the front end side of the support plate 7 is fixedly connected with a support plate for connecting the support plate 7. 7 and the clamp plate 8 fixed by the hook plate 6, the upper and lower ends of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com