Construction method for positioning and mounting underground side-by-side pipelines

A construction method, positioning and installation technology, applied in pipeline support, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems affecting pipeline positioning, quality and safety hazards, two-way pipeline positioning failure, etc., to achieve convenient positioning Fixation, simple and convenient construction, and the effect of avoiding pipe displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

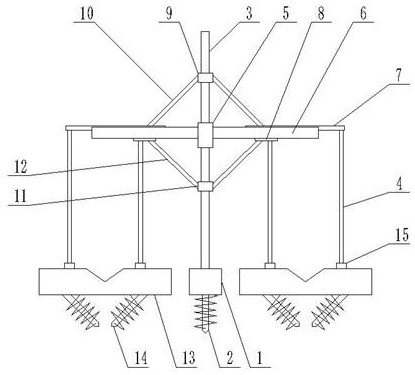

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the construction method for positioning and installing underground side-by-side pipelines in this specific embodiment includes the following steps:

[0021](1) Obtain the pipeline positioning and fixing device, including the fixed base 1. The top of the fixed base 1 is recessed with a fixed counterbore along the vertical direction, and the bottom of the fixed counterbore is pierced with a fixed perforation along the center line of the fixed counterbore. The diameter of the hole is greater than the diameter of the fixed perforation. The fixed base 1 is provided with a fixed auger rod 2. The drill bit end of the fixed auger rod 2 passes through the fixed perforation and protrudes below the fixed base 1. The drill tail of the fixed auger rod 2 The end is located in the fixed counterbore and protrudes outward along the center li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com