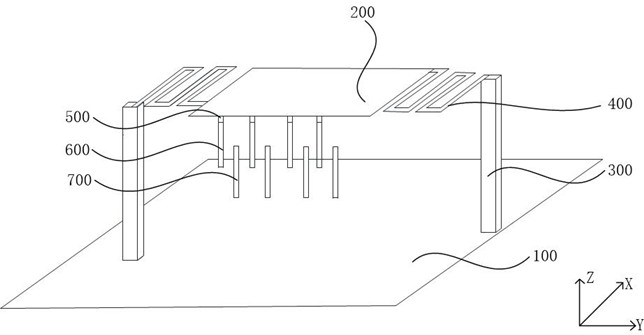

Infrared sensor chip and manufacturing method based on semiconductor double-gate transistor structure

A dual-gate transistor, infrared sensor technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

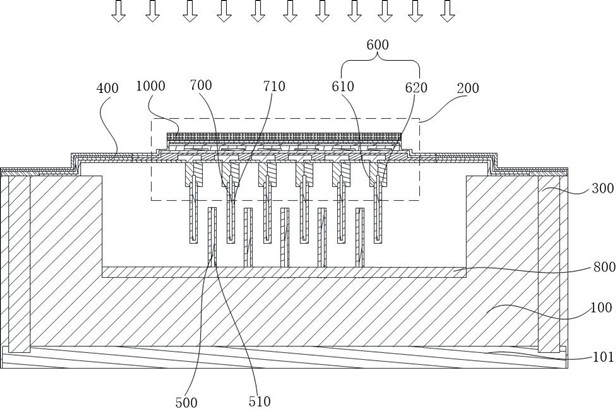

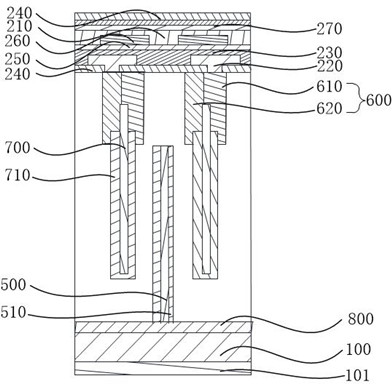

[0060] In the related art, the semiconductor infrared sensor chip has the problem of insensitivity to the detection of the intensity of light. The reason for this problem is that in the related art, the semiconductor infrared sensor chip includes a substrate on which multiple Parallel lower electrodes, an upper electrode is arranged between two adjacent lower electrodes, one end of the plurality of upper electrodes away from the substrate is connected to the floating end of the upper connection structure, and the connection end of the upper connection structure is arranged on the substrate. The upper connection structure is a cantilever beam structure, and an infrared absorption layer is also arranged on the upper connection structure. When the infrared absorption layer absorbs infrared light, the heat causes the upper connection structure to warp, which makes the upper electrode inclined relative to the lower electrode. The size of the capacitance There is no linear relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com