Lossless lightning arrester temperature rise measurement system and method

A measurement method and lightning arrester technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as the impact of residents and factory life and production activities, prevent thermal collapse, save costs, and improve measurement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

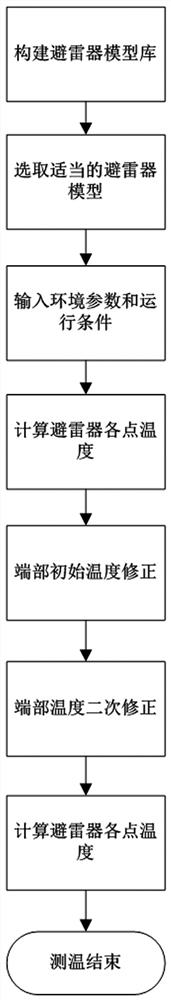

[0076] like figure 1 As shown, the embodiment of the present invention discloses a method for measuring the temperature rise of a non-destructive arrester, including the following steps:

[0077] Step A. Establish a geometric model for the structure of the arrester, and input the environmental parameters, material parameters, electrical parameters, boundary conditions, etc. of the internal components of the arrester;

[0078] The specific process of establishing the geometric model of the lightning arrester structure is as follows:

[0079] The geometric model of each component of the arrester is established and coordinated to establish a complete structural geometric model of the arrester; the environmental parameters, electrical parameters, boundary conditions, etc. of the arrester components are input according to the physical meaning of each component.

[0080] The establishment of the structural geometric model of the lightning arrester includes the following structures:...

Embodiment 2

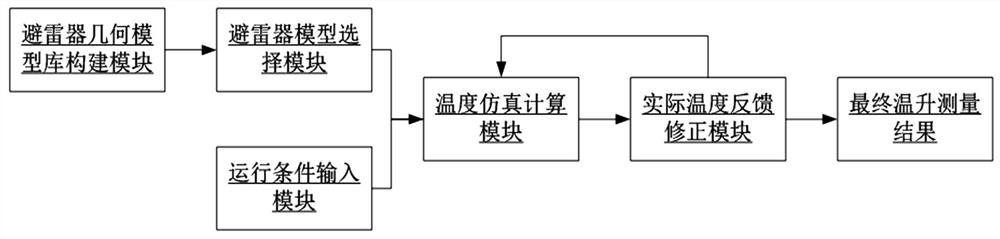

[0101] The present invention provides another embodiment. This embodiment discloses a method for measuring the temperature rise of a non-destructive arrester. The method includes the following steps:

[0102] Step A. Establish geometric models for a large number of arresters with different structures, and input the environmental parameters, material parameters, electrical parameters, boundary conditions, etc. of the internal components;

[0103] Step B. By using the thermoelectric coupling calculation method, while considering the interaction between the current and the temperature, a large number of transient curves of the internal component temperature changing with time are obtained;

[0104] Step C. Establishing a mathematical function model library of the temperature between internal components according to a large number of temperature transient curves;

[0105] Step D. For arresters of different structures, select the corresponding function model from the mathematical f...

Embodiment 3

[0108] The present invention provides another embodiment. This embodiment discloses a method for measuring the temperature rise of a non-destructive arrester. The method includes the following steps:

[0109] Step A. Establish geometric models for a large number of arresters with different structures, and input the environmental parameters, material parameters, electrical parameters, boundary conditions, etc. of the internal components;

[0110]Step B. By using the thermoelectric coupling calculation method, while considering the interaction between the current and the temperature, a large number of transient curves of the internal component temperature changing with time are obtained;

[0111] Step C. Establishing a mathematical function model library of the temperature between internal components according to a large number of temperature transient curves;

[0112] Step D. Based on the structure of the lightning arrester to be tested, in the mathematical function model libra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com