Spur gear transmission

A cylindrical gear, transmission technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve problems such as standardization restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

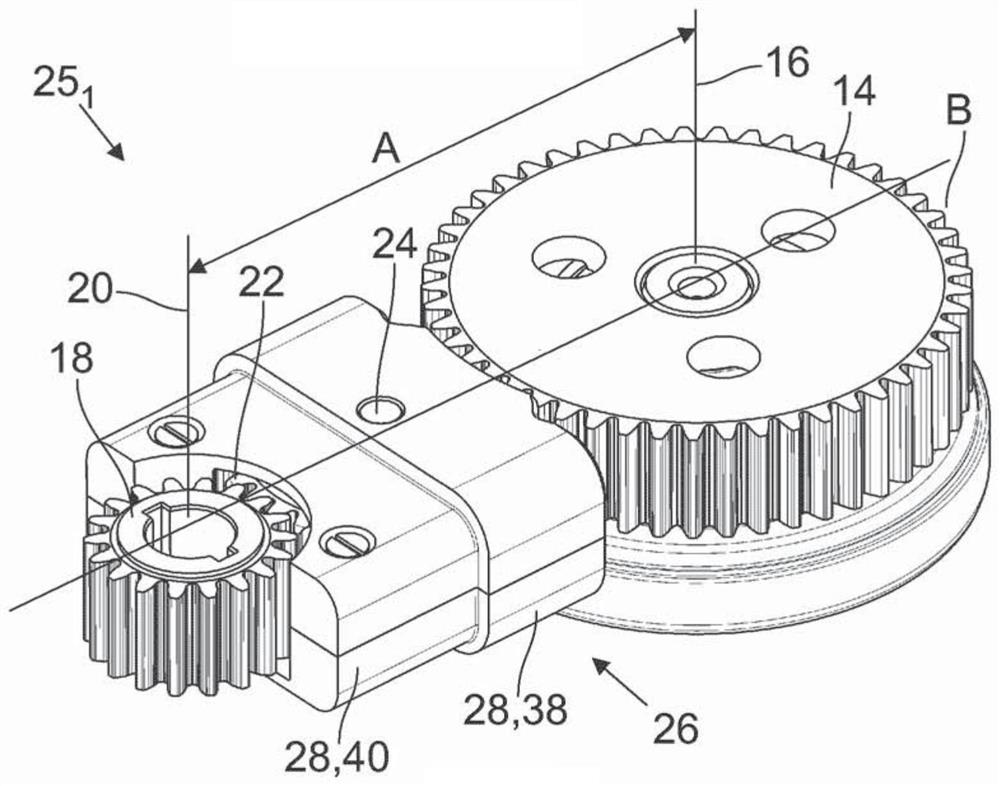

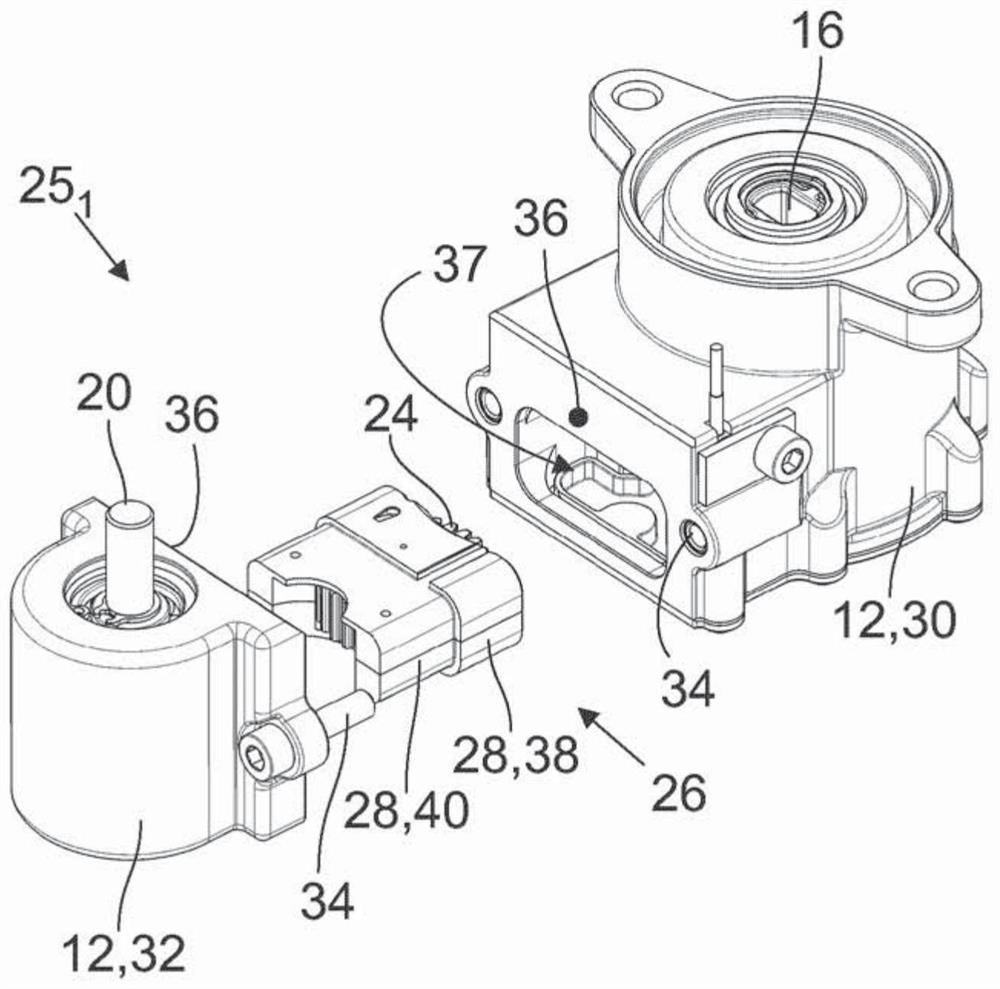

[0032] exist Figure 1A to Figure 1C A spur gear transmission 10 according to the prior art is shown in various configurations in a substantially top view. The spur gear transmission 10 has a transmission housing 12 in which an output gear 14 is mounted rotatably about a first axis of rotation 16 , a drive gear 18 is mounted rotatably about a second axis of rotation 20 , and around The third rotation shaft 24 rotatably supports the intermediate gear 22 . The first axis of rotation 16 , the second axis of rotation 20 and the third axis of rotation 24 run parallel to one another. The intermediate gear 22 meshes with the drive gear 18 and the output gear 14 such that there is no direct mesh between the drive gear 18 and the output gear 14 .

[0033] The drive gear 18 and the output gear 14 are arranged at a center distance A from each other which is the same in all three configurations. The various configurations of the spur gear transmission 10 differ as follows: While the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com