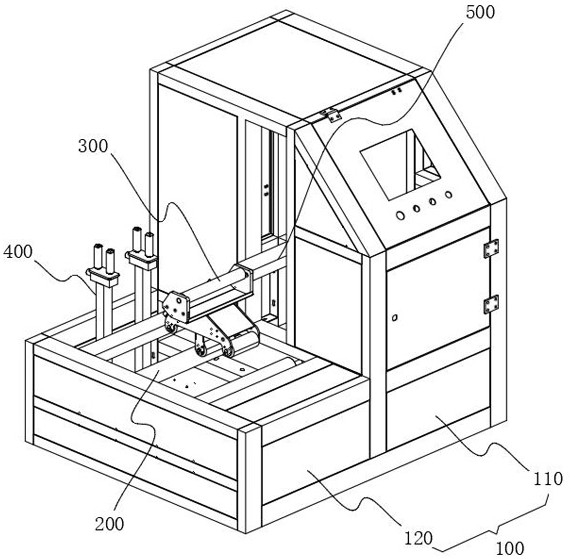

Rolling type rubber coating machine for self-sealing safety tire rubber sheet and tire rubber coating method of rolling type rubber coating machine

A safety tire and self-sealing technology, which is applied to tires, other household appliances, household appliances, etc., and can solve problems such as film warping on both sides and finale adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

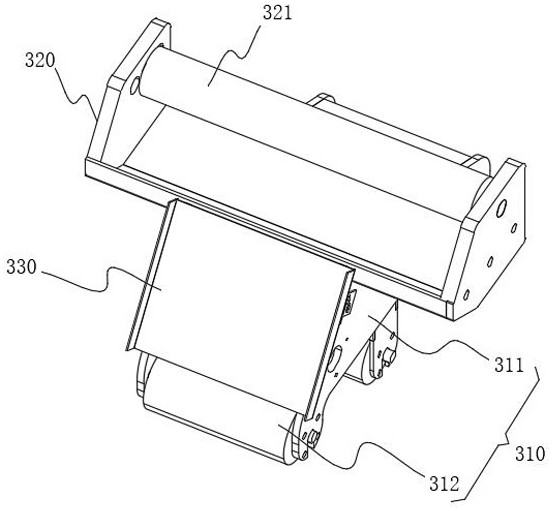

[0050] see figure 1 with figure 2 As shown, the frame body 311 is located on the side of the rubber roll 321 where the rubber layer is placed outside, and a limit plate 330 is provided. The two ends of the limit plate 330 are bent upward to form a limit groove, and the limit plate 330 is close to the finale The side of 312 is inclined, so that the rubber-covered layer is guided to the outside of the pressing shaft 312, so that the final shaft 312 can press the rubber-covered layer on the inner wall of the tire, and the limit groove can limit the rubber-covered layer, so as to solve the problem of the rubber-covered layer in the pressing process. The problem of offset is prone to occur, and the limiting plate 330 and the frame body 311 are fixed by bolts. Before use, install the limiting plate 330 that is suitable for the width of the rubber layer, thereby improving the scope of application of the limiting plate 330.

Embodiment 2

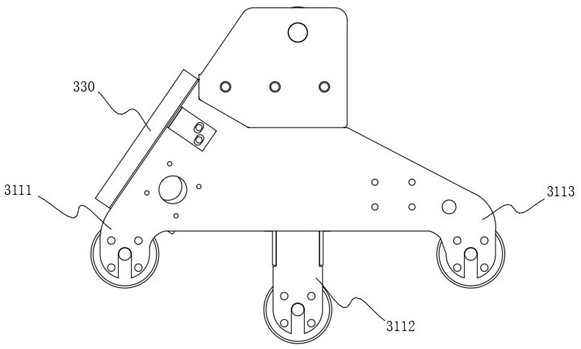

[0052] see image 3 As shown, the frame body 311 includes a driving part 3111 and a recompression part 3113. The driving part 3111 is located on the inclined side of the limit plate 330, and the recompression part 3113 is arranged on the side away from the driving part 3111. The driving part 3111 and the recompression part 3113 The bottoms of the bottoms are all equipped with final shafts 312, and are detachably connected to them, and are specifically fixed by bolts. Before use, replace the final shafts 312 with a length suitable for the width of the rubber layer. The final shafts 312 at the bottom of the driving part 3111 and the repressing part 3113 are both Driven by electric drive equipment, the motor can be used to drive alone, or the two finale shafts 312 can be driven by a motor and a belt at the same time. The latter is preferably used to save power consumption and reduce costs. The finale 312 actively drives the rubber-covered layer to be released, thereby improving t...

Embodiment 3

[0055] see Figure 4 As shown, the top of the drive cabinet 120 is also provided with a tire stopper 400, the tire stopper 400 includes a pneumatic flip plate 420, the top of the pneumatic flip plate 420 is rotated along the longitudinal direction and is connected with a plurality of stop bars 430, and the bottom of the pneumatic flip plate 420 is set Bracket 410, the bracket 410 is fixedly connected with the drive cabinet 120 and then supports the pneumatic flip plate 420. When in use, the stop bar 430 is clamped on both sides of the tire to limit the tire and prevent it from tilting, further ensuring that the tire is in the Stability during rotation.

[0056] In addition, the pneumatic turning plate 420 is connected to the bracket 410 through a hinge shaft, and is turned over by pneumatic action, and then the distance between the stop bar 430 and the tire is changed by turning to adapt to the use of tires with different inner diameters.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap