Aerial longitudinal and transverse bullet train

A technology of motor train and lateral drive, applied in the direction of motor vehicles, railway vehicles, trolley cranes, etc., can solve the problems of weak aerial lifting capacity and small service range, and achieve strong lifting capacity, save land, and enhance the ability of anti-risk and disaster relief. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

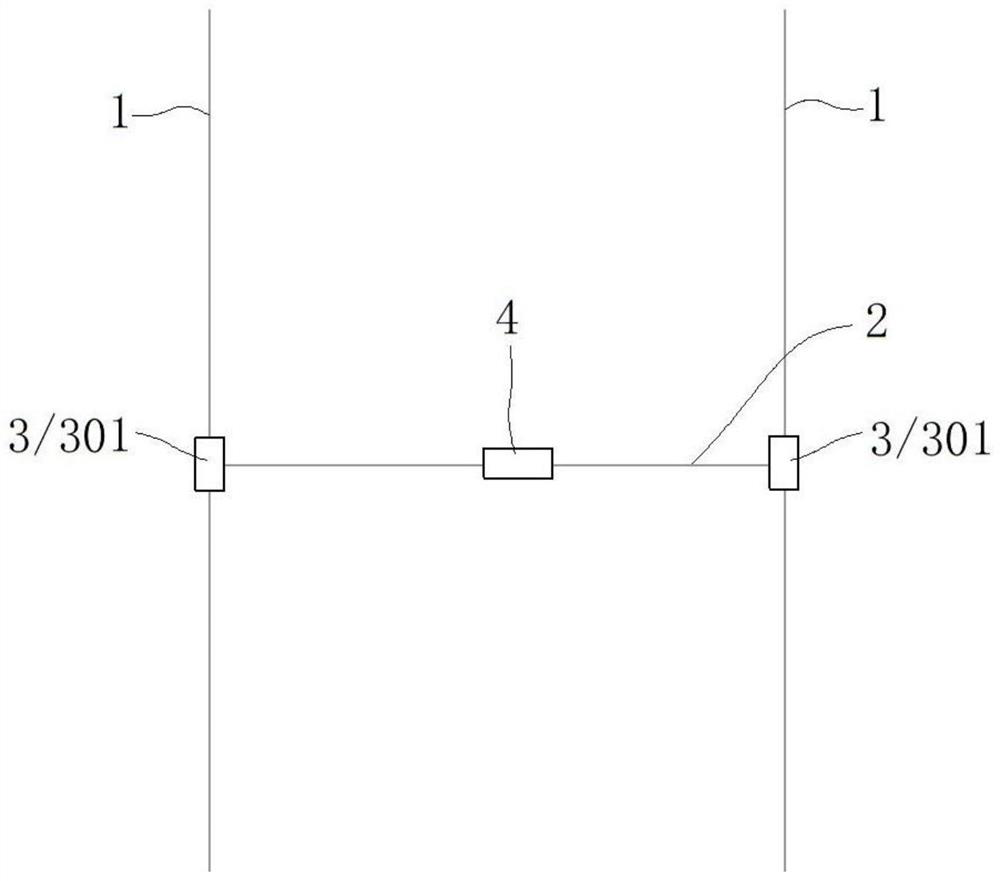

[0051] This embodiment provides a vertical and horizontal moving vehicle in the air, such as figure 1 As shown, in a preferred embodiment, it includes two parallel longitudinal rails 1, a transverse rail 2 arranged across the two longitudinal rails 1, and a longitudinal drive device that drives the transverse rail 2 to run on the longitudinal rail 1 3. And the first motor car 4 that is connected to the transverse track 2 and can run on the transverse track 2 .

[0052] In the present invention, the first motor car 4 is a motor car with a power plant, and the master control room is responsible for issuing a driving instruction. The first motor car 4 can be a single car, or two and more cars; certainly the first motor car 4 can also be a suspension car suspended on the transverse rail 2, similar to a cable car.

[0053] The transverse track 2 of this embodiment runs on the longitudinal track 1 through the longitudinal driving device 3, so that the first moving car 4 moves longi...

Embodiment 2

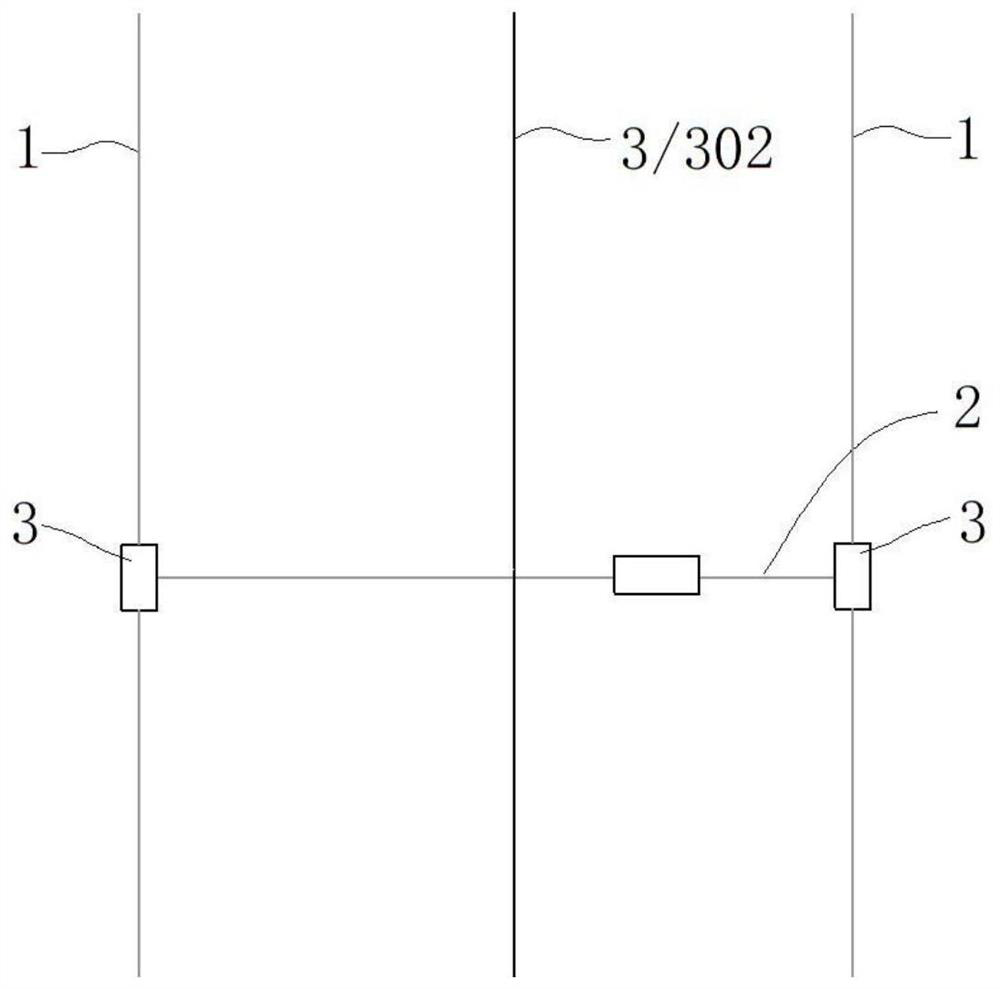

[0066] The structural principle of this embodiment is basically the same as that of the first embodiment, except that the way of driving the transverse track 2 to run on the longitudinal track 1 is different. Such as figure 2 As shown, in this embodiment, regardless of whether the longitudinal rail 1 is horizontal or inclined, the lateral rail 2 is connected with the longitudinal rail 1 and can slide on the longitudinal rail 1. The two ends of the lateral rail 2 are respectively provided with a Set of Scooter Wheels. The longitudinal driving device 3 is a power traction cable 302 connected to the transverse track 2. Under the action of the power traction cable 302, the transverse track 2 runs on the longitudinal track 1 through the sliding wheels to realize the longitudinal movement of the first motor car 4.

Embodiment 3

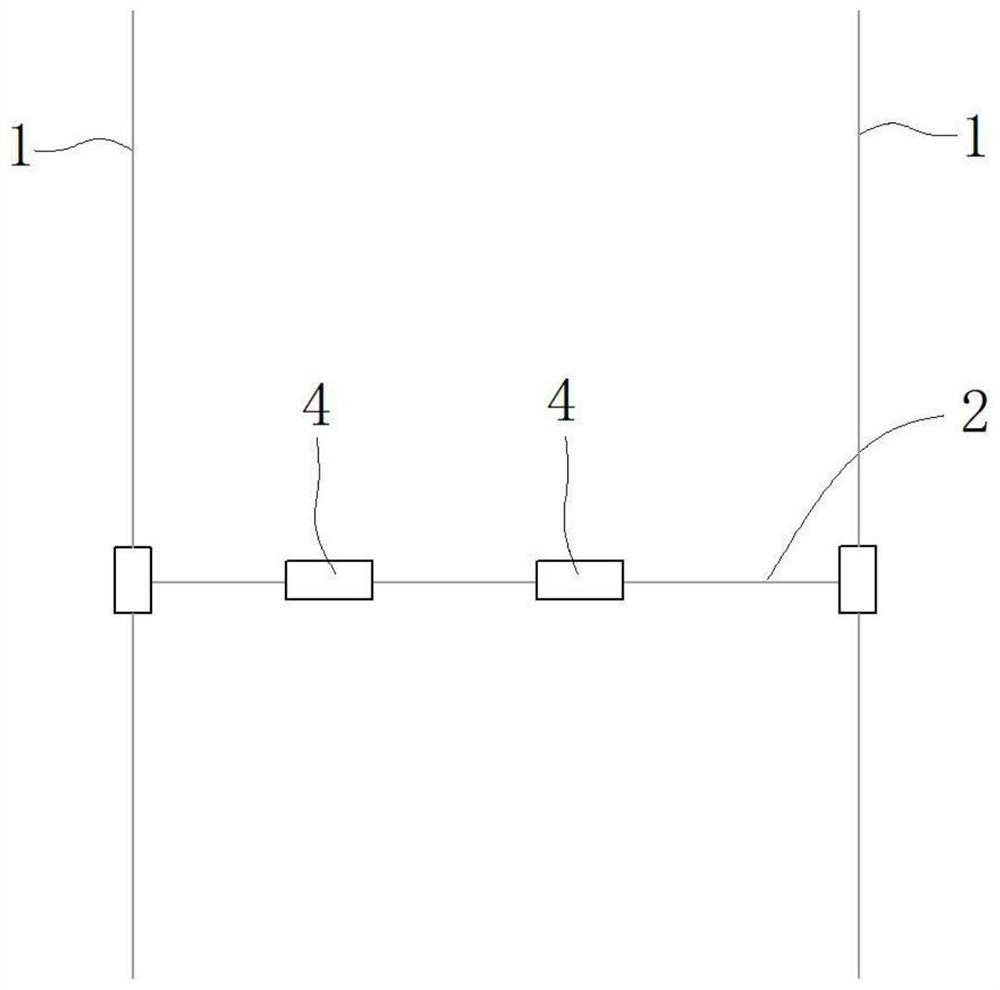

[0068] The structural principle of this embodiment is basically the same as that of Embodiment 1 and Embodiment 2, except that the number of first motor cars 4 arranged on the transverse track 2 is different. Such as image 3 As shown, in this embodiment, the number of first motor cars 4 set on one transverse track 2 is two or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com