A kind of flocculant with network interpenetrating structure and preparation method thereof

A network interpenetrating, flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor water solubility, small molecular weight, and uneven charge distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

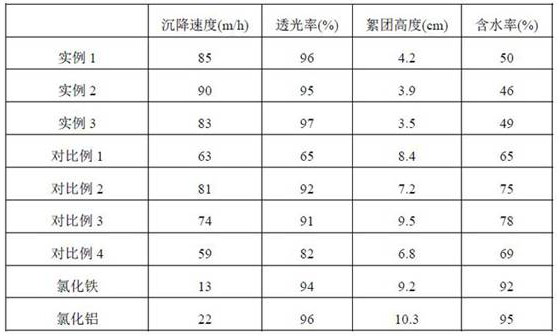

Examples

preparation example Construction

[0017] In a first aspect, the present invention provides a method for preparing a flocculant with an interpenetrating network structure, wherein the method comprises the following steps:

[0018] (1) Preparation of nano-sol

[0019] Mix ferric chloride, aluminum chloride and the first part of water, then dropwise add lye; raise the temperature of the system to the reaction temperature, then react for 3-5 hours (for example, 4 hours) while stirring; add the second part of water Dilute and then ripen for 18-30 hours (for example, 21, 24 or 27 hours) to obtain a nano-sol;

[0020] (2) Synthesis of flocculant

[0021] Dissolve acrylamide, temperature responsive monomer, pH responsive monomer, stabilizer, structure regulator and dispersant in the nano-sol prepared in step (1); adjust the system temperature to 10-12°C (eg 11°C ) and transferred to the reaction kettle, nitrogen deoxygenation for 50-70 minutes (for example, 60 minutes); adding the amount of initiator to initiate the...

Embodiment 1

[0033] This embodiment prepares a flocculant with a network interpenetrating structure, and the preparation method includes the following steps:

[0034] (1) Nano-sol preparation:

[0035] Mix 1 part of ferric chloride, 6 parts of aluminum chloride and 100 parts of water, add 7 parts by weight of 50% sodium hydroxide solution dropwise to the system, raise the temperature of the system to 75 ° C, and stir at 1000 rpm Then react for 4 hours, then add 550 parts of water to dilute, and ripen for 24 hours for later use.

[0036] (2) Synthesis of flocculant:

[0037] Add 120 parts of acrylamide, 80 parts of N,N-dimethylacrylamide (temperature-responsive monomer), 5 parts of N,N-dimethylallyl octadecyl to the nano-sol prepared in step (1) Ammonium chloride (pH response monomer), 10 parts of PEG4000 (stabilizer), 0.005 parts of N,N-methylenebisacrylamide (structure modifier) and 5 parts of AEO-9 (dispersant), after fully dissolved, Control the temperature of the system within the...

Embodiment 2

[0039] In this embodiment, a flocculant with a network interpenetrating structure is prepared, and the preparation method includes the following steps:

[0040] (1) Nano-sol preparation:

[0041] Mix 2 parts of ferric chloride, 10 parts of aluminum chloride and 140 parts of water, add 10 parts by weight of 50% sodium hydroxide solution dropwise to the system, raise the temperature of the system to 80°C, and stir at 1500 rpm React for 4 hours, then add 600 parts of water to dilute, and ripen for 24 hours for later use.

[0042] (2) Synthesis of flocculant:

[0043] Add 140 parts of acrylamide, 100 parts of N,N-diethylacrylamide (temperature responsive monomer), 10 parts of hexadecyldimethylallyl ammonium chloride ( pH response monomer), 15 parts of PVP K90 (stabilizer), 0.01 part of pentaerythritol triallyl ether (structure regulator) and 10 parts of lauryl amidopropyl sulfobetaine (dispersant), after fully dissolved, the Adjust the temperature of the system to 10-12°C, tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com