Preparation method of environment-responsive super-hydrophobic-hydrophilic reversible conversion material surface

An environmentally responsive, super-hydrophobic technology, applied in paper coatings, fiber raw material treatment, liquid-repellent fibers, etc., can solve the problem of less research on the preparation of microcapsule super-hydrophobic surfaces, and achieve excellent dispersion stability and low cost. , the effect of micro-scale structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

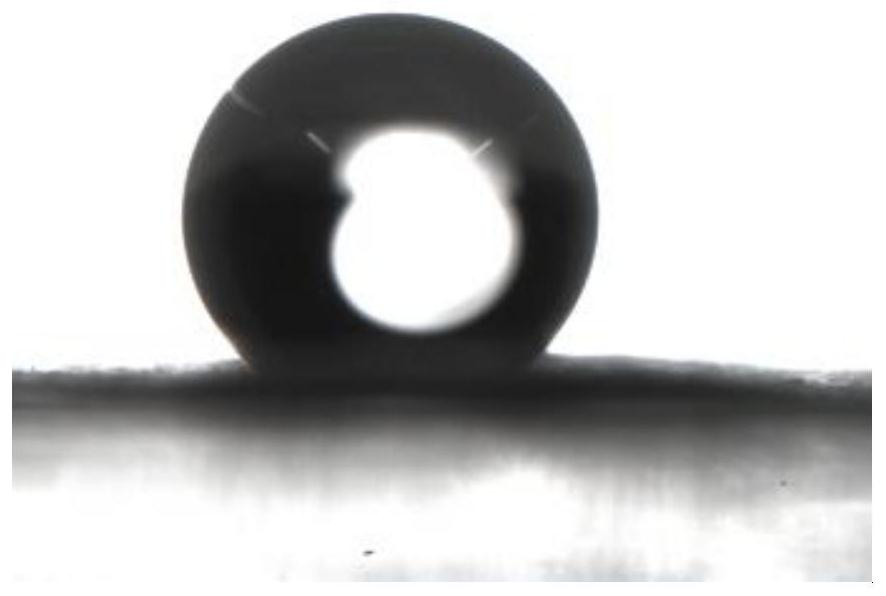

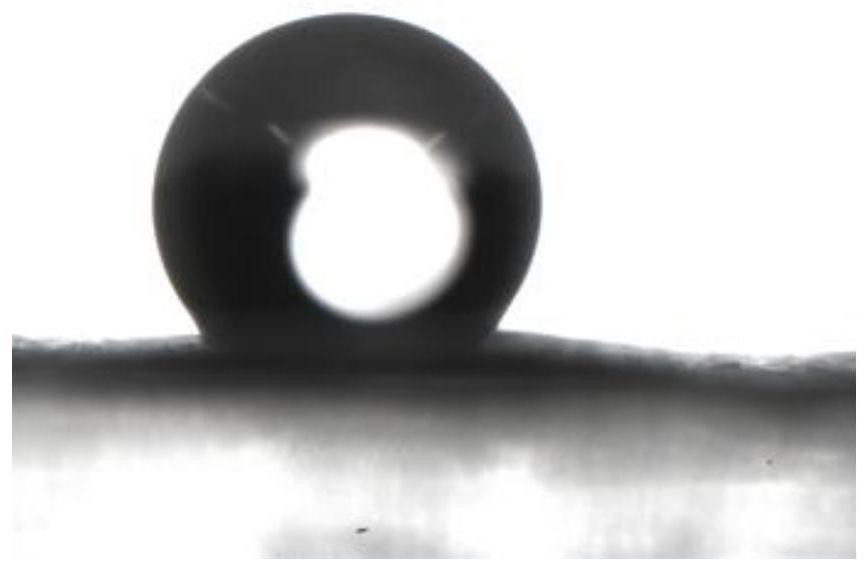

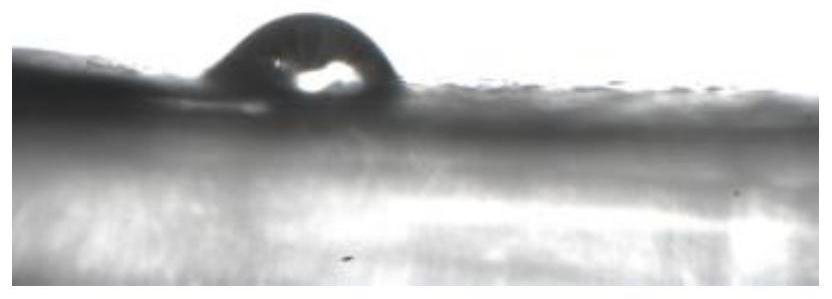

Embodiment 1

[0036] Step 1, using diethylaminoethyl methacrylate, styrene, nonafluorohexyl methacrylate, and glycidyl methacrylate as monomers, azobisisobutyronitrile as a thermal initiator, and divinylbenzene as Cross-linking agent, hexadecane as stabilizer, the above materials as oil phase, choose sodium dodecylbenzenesulfonate (SDBS) as surfactant and dissolve in deionized water as continuous phase (water phase). After fully mixing the oil phase, under the high-speed stirring of the homogenizer, drop the oil phase into the water phase to emulsify for 20 minutes. After forming a white emulsion and standing for 30min until the emulsion is stable, it is moved into a three-necked flask, and the -1 React for 8 hours under mechanical stirring, the temperature is controlled at 80°C, after centrifugation and cleaning, dry in a vacuum oven at 80°C for 24 hours, and then store in vacuum to obtain environment-responsive microcapsules;

[0037] In step one, the monomer molar ratio of diethylaminoe...

Embodiment 2

[0041] Step 1, using diethylaminoethyl methacrylate, styrene, nonafluorohexyl methacrylate, and glycidyl methacrylate as monomers, azobisisobutyronitrile as a thermal initiator, and divinylbenzene as Cross-linking agent, hexadecane as stabilizer, the above materials as oil phase, choose sodium dodecylbenzenesulfonate (SDBS) as surfactant and dissolve in deionized water as continuous phase (water phase). After fully mixing the oil phase, under the high-speed stirring of the homogenizer, drop the oil phase into the water phase to emulsify for 30 minutes. Form a white emulsion and let it stand for 30min until the emulsion is stable, then move it into a three-necked flask, -1 React for 10 hours under mechanical stirring, the temperature is controlled at 80°C, after centrifugation and cleaning, dry in a vacuum oven at 80°C for 24 hours, and then store in vacuum to obtain environment-responsive microcapsules;

[0042] In step 1, the monomer ratio of diethylaminoethyl methacrylate, ...

Embodiment 3

[0046] Step 1, using diethylaminoethyl methacrylate, styrene, nonafluorohexyl methacrylate, and glycidyl methacrylate as monomers, azobisisobutyronitrile as a thermal initiator, and divinylbenzene as Cross-linking agent, hexadecane as stabilizer, the above materials as oil phase, choose sodium dodecylbenzenesulfonate (SDBS) as surfactant and dissolve in deionized water as continuous phase (water phase). After fully mixing the oil phase, under the high-speed stirring of the homogenizer, drop the oil phase into the water phase to emulsify for 25 minutes. After forming a white emulsion and standing for 30min until the emulsion is stable, it is moved into a three-necked flask, and the -1 React for 9 hours under mechanical stirring, the temperature is controlled at 70°C, after centrifugation and cleaning, dry in a vacuum oven at 60°C for 24 hours, and then store in vacuum to obtain environment-responsive microcapsules;

[0047] In step 1, the monomer ratio of diethylaminoethyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com