An intelligent fiber with environmental responsiveness or its product and its preparation method

An environmentally responsive, fiber product technology, applied in the direction of carbon fiber, plant fiber, fiber processing, etc., can solve the problems of limiting fiber strength and application environment, complexity, limiting the universality of preparation methods, and the applicability of smart fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Disperse 10 mg of polyacrylamide particles containing carboxyl groups in 50 ml of water, add 0.05 g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, and then add functionalized polyester containing amino groups 0.5 g of fiber was reacted at 20° C. for 4 hours, and then washed with water to obtain intelligent polyester fiber.

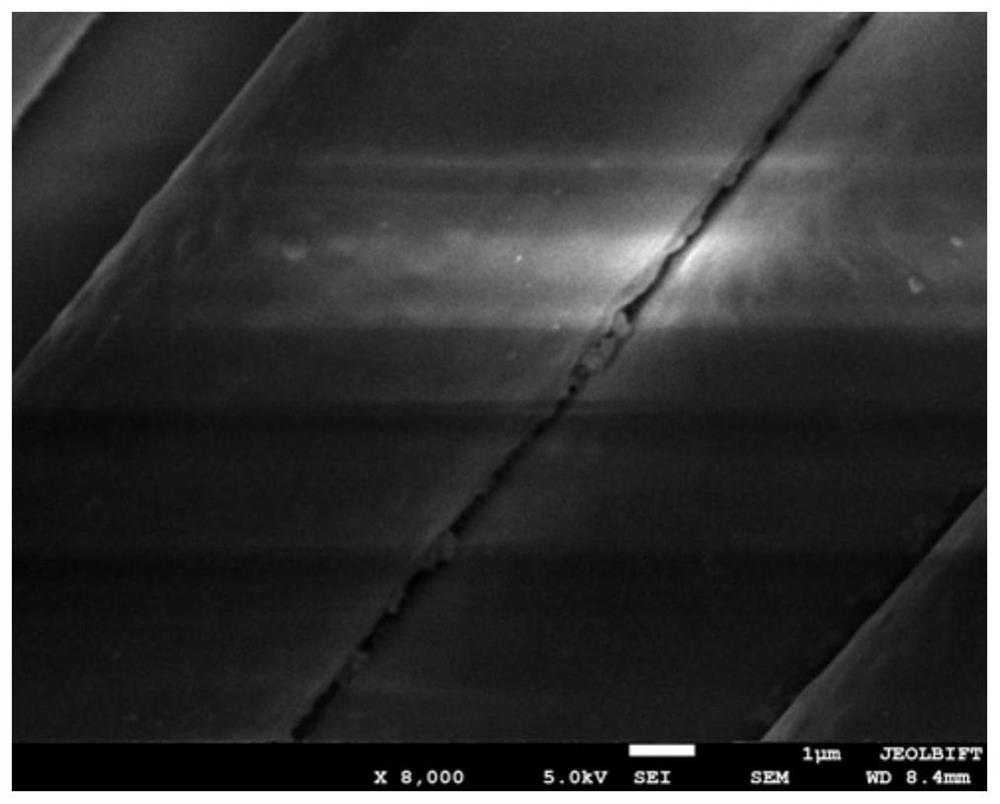

[0049] The above intelligent polyester fiber is woven into intelligent polyester cloth, and its SEM image is as follows figure 1 As shown, it can be seen from this figure that the particles are distributed on the surface of the fiber to obtain a fiber with a rough surface.

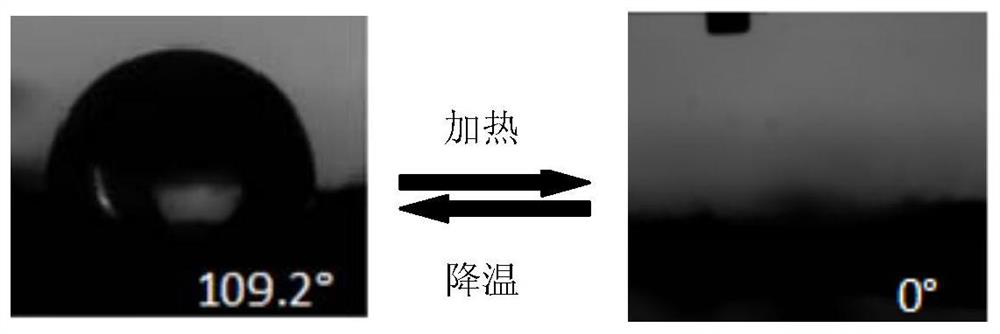

[0050] The hydrophilic and hydrophobic properties of the intelligent polyester cloth prepared in this embodiment change under the change of temperature, such as figure 2 As shown, under the condition of lower than 30°C, the contact angle of the smart polyester cloth to water is 109.2°, which has hydrophobic properties; when heated to 80°C, the contact angle of...

Embodiment 2

[0054] Disperse 10mg of N,N'-diethylacrylamide and methylpropanesulfonic acid copolymer particles in 50ml of water, add 0.1g of N-hydroxysuccinimide, and then add 0.5g of aminated polypropylene fiber, at 20°C The reaction was carried out for 4 hours, and then washed with water to obtain intelligent polypropylene fibers.

[0055]The hydrophilicity and hydrophobicity of the intelligent polypropylene fiber prepared in this example change reversibly under the change of temperature: when the temperature rises, its hydrophobicity increases; when the temperature decreases, its hydrophilicity increases.

[0056] The hydrophilicity and hydrophobicity of the intelligent polypropylene fiber prepared in this example change reversibly under the change of pH value: when the pH value increases, its hydrophilicity increases, and when the pH value decreases, its hydrophobicity increases.

Embodiment 3

[0058] Disperse 10 mg of carboxyl-containing polyvinylpyridine particles in 50 ml of water, add 0.1 g of N-hydroxysuccinimide, and then add 0.5 g of aminated carbon fiber, react at 25°C for 4 hours, and then wash with water to obtain smart carbon fiber.

[0059] The hydrophilicity and hydrophobicity of the smart carbon fiber prepared in this embodiment change reversibly under the change of pH value: when the pH value increases, its hydrophobicity increases, and when the pH value decreases, its hydrophilicity increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com