A kind of lignin/inorganic oxide pickering emulsion with double pH responsiveness and preparation method thereof

A technology of inorganic oxide and lignin, which is applied in the field of lignin/inorganic oxide pickering emulsion and its preparation, can solve problems such as limiting application range, increasing application cost, equipment corrosion, etc., and achieves cost reduction, corrosion reduction, and salt reduction the cumulative effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 100 parts by weight of pine alkali lignin solid and dissolve it in water, prepare a suspension with a concentration of 20% by weight, adjust the pH value to 9 with NaOH with a mass concentration of 20%, heat to 50°C, and add 5 parts by weight of bromine Acetic acid was reacted at 50° C. for 1 h, then 50 parts by weight of 3-chloro-2-hydroxypropyltrimethylammonium chloride was added, reacted at 50° C. for 4 h, and amphoteric lignin was obtained after drying.

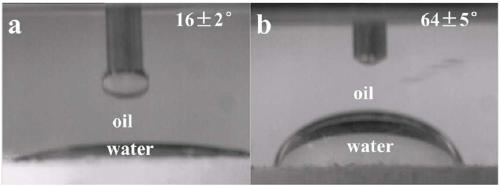

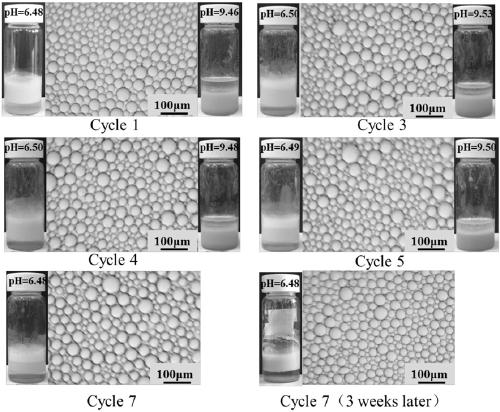

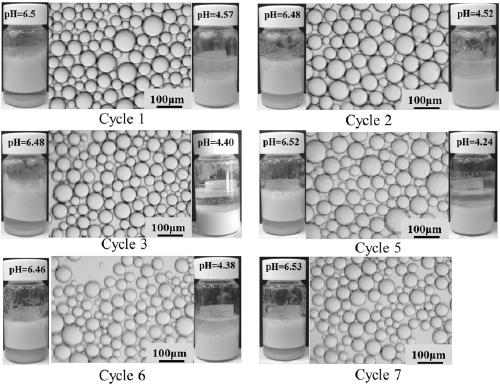

[0041] Take the above-mentioned amphoteric lignin, add water to dissolve it, configure a solution with a weight percentage of 5%, and then add HCl with a mass concentration of 20% to adjust the pH to about 6.5. Then add 0.1 parts by weight of titanium dioxide, ultrasonically disperse to obtain a mixed solution of lignin / titanium dioxide, then add 400 parts by weight of n-decane, and emulsify at 11000 rpm for 5 minutes to obtain a lignin / titanium dioxide pickering emulsion.

Embodiment 2

[0043] Take 50 parts by weight of bamboo pulp alkali lignin and 50 parts by weight of reed alkali lignin solid and dissolve them in water, prepare a suspension with a concentration of 30% by weight, adjust the pH value to 10 with NaOH with a mass concentration of 20%, and heat to 60°C, add 10 parts by weight of sodium chloroacetate, and react at 60°C for 3 hours. Then add 40 parts by weight of 2,3-epoxypropyltrimethylammonium chloride, react at 60° C. for 3 hours, and obtain amphoteric lignin after drying.

[0044] The above-mentioned amphoteric lignin was taken, dissolved in water, and a solution with a weight percentage of 1% was prepared, and then HCl with a mass concentration of 20% was added to adjust the pH to 7. Then add 10 parts by weight of silicon dioxide, ultrasonically disperse to obtain a mixed solution of lignin / silicon dioxide, then add 200 parts by weight of toluene, and emulsify at 16000 rpm for 3 minutes to obtain a lignin / silicon dioxide pickering emulsion. ...

Embodiment 3

[0046] Dissolve 100 parts by weight of wheatgrass lignin solid in water, prepare a suspension with a concentration of 40% by weight, adjust the pH value to 11 with NaOH with a mass concentration of 20%, heat to 70°C, and add 15 parts by weight of Chloroacetic acid, reacted at 70°C for 2h, then added 10 parts by weight of 3-chloro-2-hydroxypropyltrimethylammonium chloride and 10 parts by weight of 2,3-epoxypropyltrimethylammonium chloride, React at 70°C for 2 hours, and obtain amphoteric lignin after drying.

[0047] The above-mentioned amphoteric lignin was taken, dissolved in water, and a solution with a weight percentage of 2% was prepared, and then HCl with a mass concentration of 20% was added to adjust the pH to 6. Then add 20 parts by weight of zinc oxide, ultrasonically disperse to obtain a lignin / zinc oxide mixed solution, then add 150 parts by weight of dichloromethane, and emulsify at 20000 rpm for 2 minutes to obtain a lignin / zinc oxide pickering emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com