Preparation method of sporopollen-based copper preparation pesticide carrier

A sporopollenin and copper preparation technology, which is applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve problems such as difficult modification or processing, and limited application range of sporopollenin. To achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

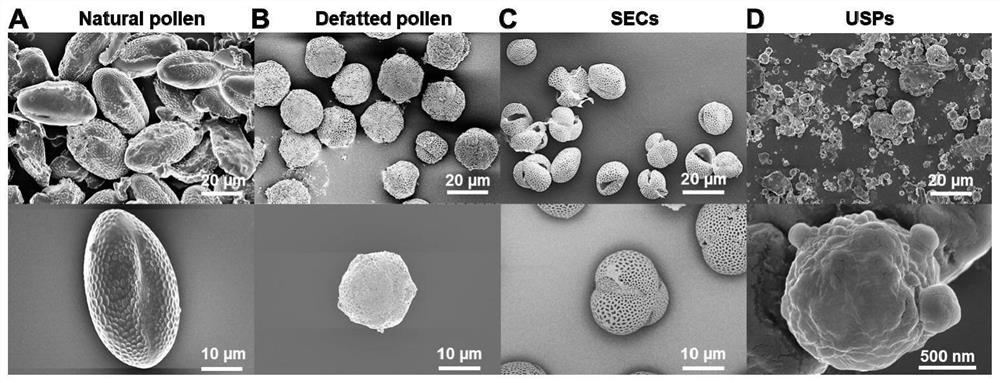

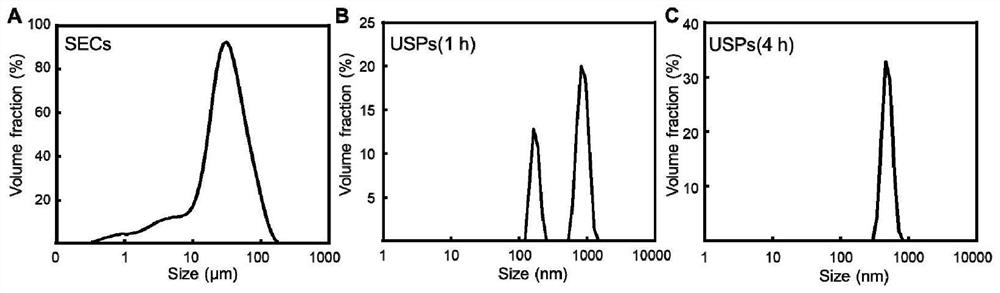

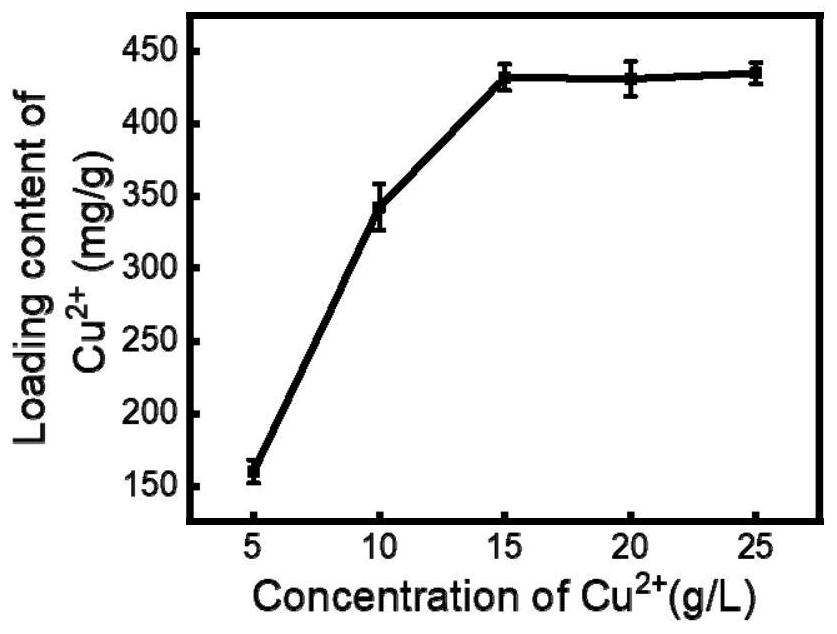

[0047] In step 1, rape pollen (100g, Henan Zhuoyu Bee Industry Co., Ltd.) was placed in hot acetone (80mL, 50°C, Sinopharm Holding Co., Ltd.) and stirred (220rpm) for 2h, then poured out through acetone, and 1 liter of water was added and stirred for 10 hours. After that, the water was removed by vacuum filtration, and the washed pollen was stirred and refluxed in acetone (80 mL, 50° C.) for 2 h. After that, the pollen was collected by vacuum filtration, transferred to a glass dish, and dried in a fume hood. Get defatted pollen.

[0048] Step 2, adding defatted pollen (20 g) to 85% (v / v) phosphoric acid (100 mL, Sinopharm Holding Co., Ltd.), and keeping stirring and refluxing at 80° C. for 2 hours to degrade the spore protoplasmic components and obtain sporopollen The sporopollenin microcapsules were collected by vacuum filtration and washed successively with the following solvents (50 mL): water (twice), acetone (twice) and ethanol (twice), and the sporopollenin microcapsules...

Embodiment 2

[0054] Step 1, put camellia pollen (100g) in hot acetone (200mL, 50°C) and stir (220rpm) for 2h, then pour out acetone, add 1 liter of water and stir for 10 minutes, then remove the water by vacuum filtration, wash with water The pollen was stirred and refluxed again in hot acetone (200 mL, 50° C.) for 2 h, and then the pollen was collected by vacuum filtration, transferred to a glass dish, and dried in a fume hood to obtain defatted pollen.

[0055]Step 2, adding defatted pollen (20 g) into 85% (v / v) phosphoric acid (200 mL), and keeping stirring and refluxing at 80° C. for 5 hours to degrade the sporozoite components and obtain sporopollen microcapsules. The sporopollenin microcapsules were collected by vacuum filtration and washed successively with the following solvents (50 mL): water (twice), acetone (twice) and ethanol (twice), the sporopollenin microcapsules were transferred to a glass dish and Dry in a fume hood.

[0056] Step 3, add sporopollenin microcapsules (10g) ...

Embodiment 3

[0058] Step 1, put pine pollen (100g) in hot acetone (200mL, 50°C) and stir (220rpm) for 0.5h, then pour out acetone, add 1 liter of water and stir for 10 minutes, and then remove the water by vacuum filtration. The washed pollen was stirred and refluxed again in hot acetone (200 mL, 50° C.) for 0.5 h, and then the pollen was collected by vacuum filtration, transferred to a glass dish, and dried in a fume hood to obtain defatted pollen.

[0059] Step 2, adding defatted pollen (20 g) into 75% (v / v) phosphoric acid (60 mL), and keeping stirring and refluxing at 80° C. for 8 hours to degrade the sporozoites and obtain sporopollen microcapsules. The sporopollenin microcapsules were collected by vacuum filtration and washed successively with the following solvents (50 mL): water (twice), acetone (twice) and ethanol (twice), and the sporopollenin microcapsules were transferred to a glass dish and placed in Dry in a fume hood.

[0060] Step 3, add sporopollenin microcapsules (10g) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com