Steel for engine connecting rod and production method thereof

A technology of an engine connecting rod and a production method, which is applied in the field of steel material manufacturing and can solve problems such as large fluctuations in S and N content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

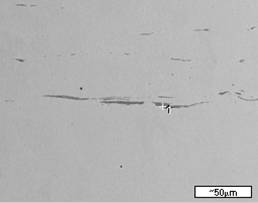

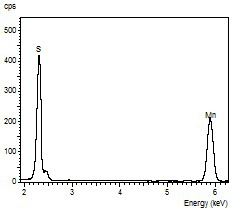

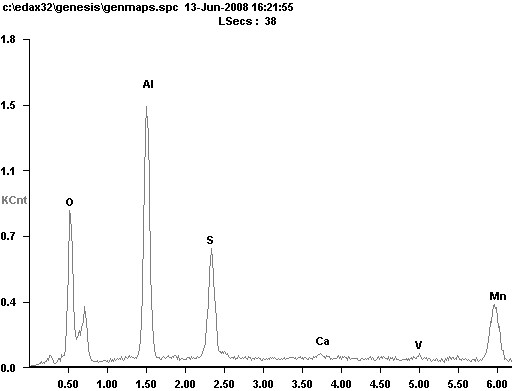

Image

Examples

Embodiment 1

[0043] A steel for an engine connecting rod in this embodiment, its chemical composition and its mass percentage are: C 0.70%, Si 0.18%, Mn 0.57%, P 0.022%, S 0.064%, Cr 0.13%, Ni 0.060% , V 0.035%, Al 0.004%, N0.0155%, O 0.0016%, and the rest are Fe and unavoidable impurities.

[0044] A kind of production method of steel for engine connecting rod of the present embodiment, comprises the following steps:

[0045] (1) Converter smelting

[0046] ① At the end of smelting, control C 0.25%, P 0.018%, tapping temperature T=1580 ℃, and use sliding plate to stop slag;

[0047] ② Add aluminum ingots to the molten steel during the tapping process. The amount of aluminum ingots added per ton of molten steel is 2.8 Kg, and other elements are added according to the chemical composition requirements;

[0048] (2) LF refining

[0049] ① The refining furnace produces low-basicity slag, and the basicity is controlled at 1.5. The composition and weight percentage of the refining slag are C...

Embodiment 2

[0062] With reference to embodiment 1 of the present invention, the present invention has also carried out other four embodiments, has also carried out a comparative example according to traditional process simultaneously, and the chemical composition list in embodiment 1-5 and comparative example 1 is referring to following table 1, implements See Table 2 below for the list of process parameters in Examples 1-5 and Comparative Example 1, and see Table 3 below for the performance test results of steel prepared using the chemical composition in Table 1 and the process parameters in Table 2 respectively.

[0063] Table 1 The chemical composition of each embodiment of the present invention and comparative example

[0064]

[0065] Table 2 The key process parameters of each embodiment of the present invention and comparative examples

[0066]

[0067] Table 3 List of performance, tissue and inclusion detection and analysis results of each embodiment of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com