Dyeing and finishing device and method for processing one-way moisture-conducting knitted fabric

A knitted fabric, unidirectional moisture-conducting technology, applied in the direction of processing textile material equipment configuration, textile material processing, processing textile material carrier, etc. Improves spinning quality, prevents dye settling and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Transport the produced unidirectional moisture-wicking knitted fabric to the dyeing and finishing workshop for dyeing and finishing. The width of the fabric is 1.5 meters. After arriving in the dyeing and finishing workshop, the surface is pre-cleaned immediately, and the internal moisture content is guaranteed not to exceed 30 %, and then transport it to the dyeing and finishing device for unidirectional moisture-wicking knitted fabric processing for dyeing and finishing operations. In the dyeing and finishing workshop, there are multiple sets of 220V power supplies for unidirectional moisture-wicking knitted fabric processing dyeing and finishing devices.

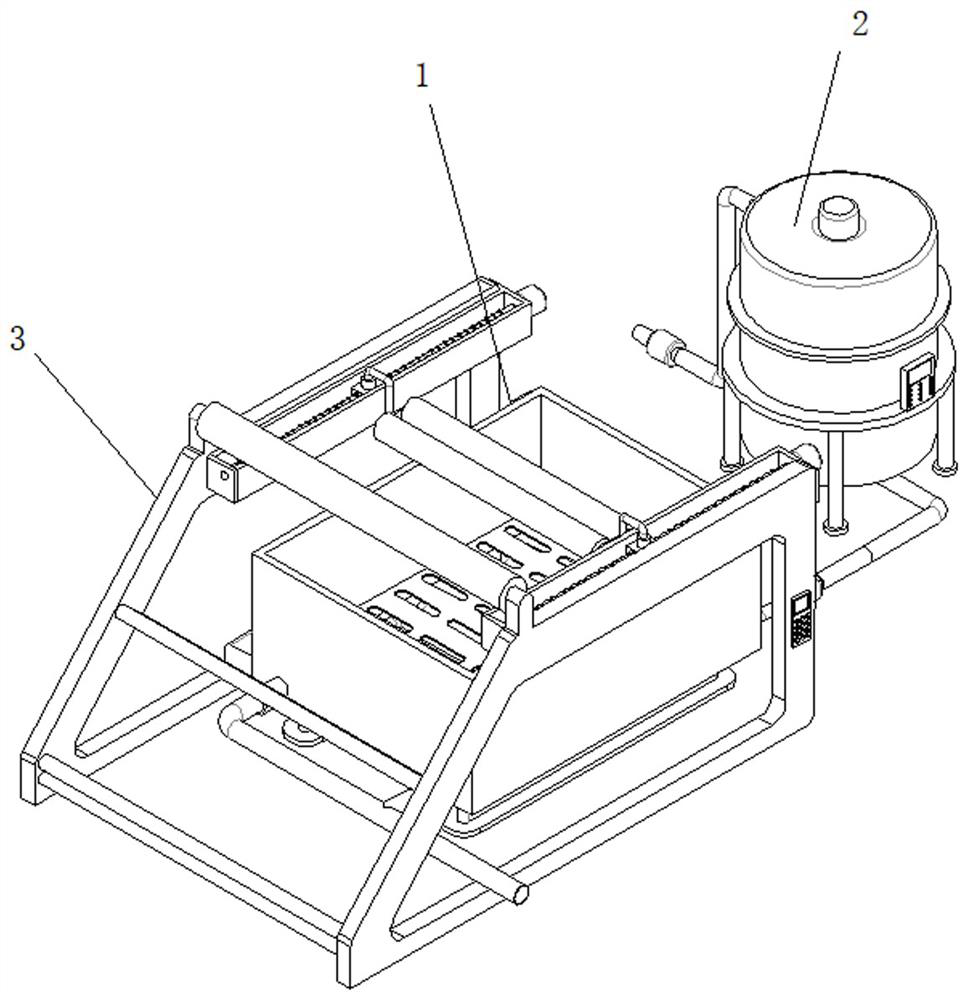

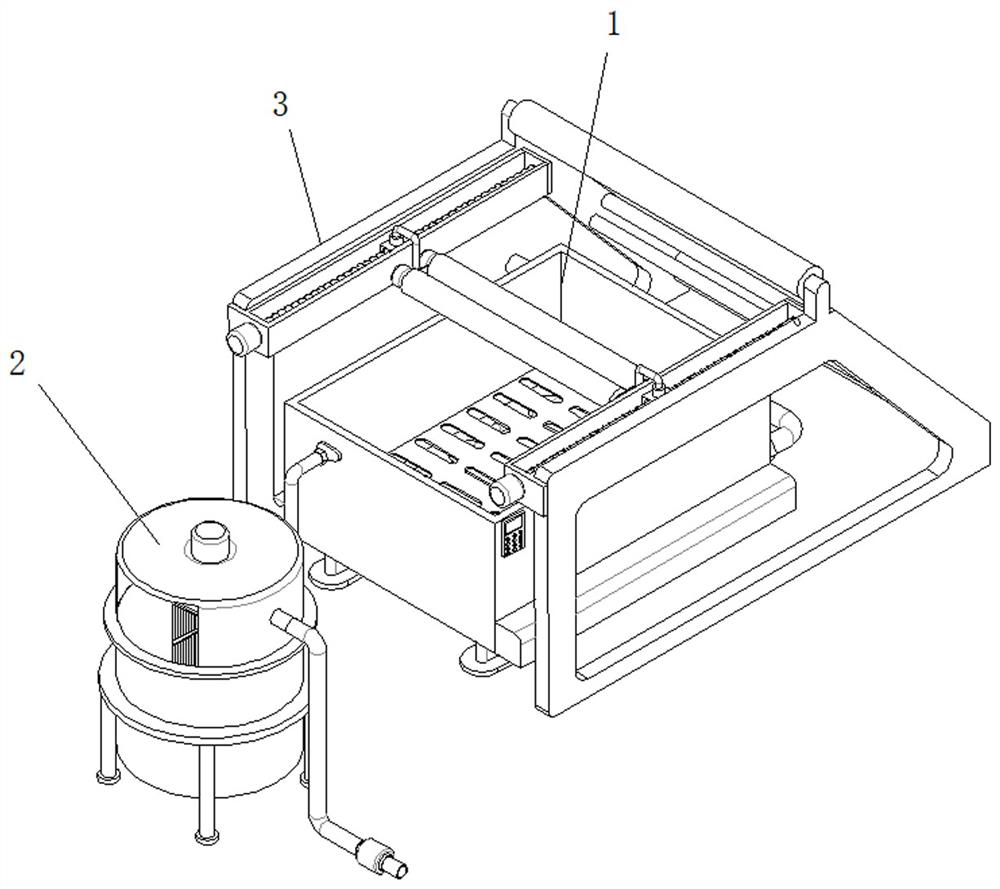

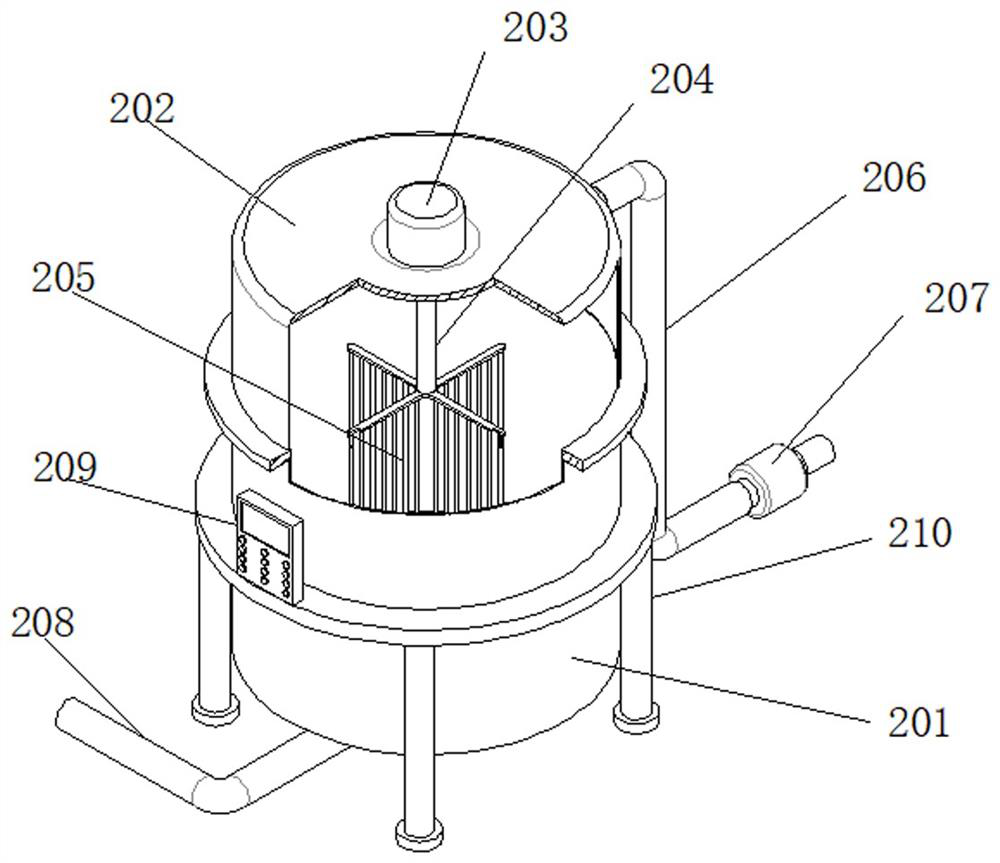

[0040] Such as Figure 1-7Shown is a dyeing and finishing device for unidirectional moisture-wicking knitted fabric processing provided by the present invention. The equipment mainly includes a dyeing mechanism 1 containing a liquid dye and a finishing mechanism 3 for adjusting the fabric. The two cooperate with eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com