Circular ash conveyer

A ash conveyor, annular technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

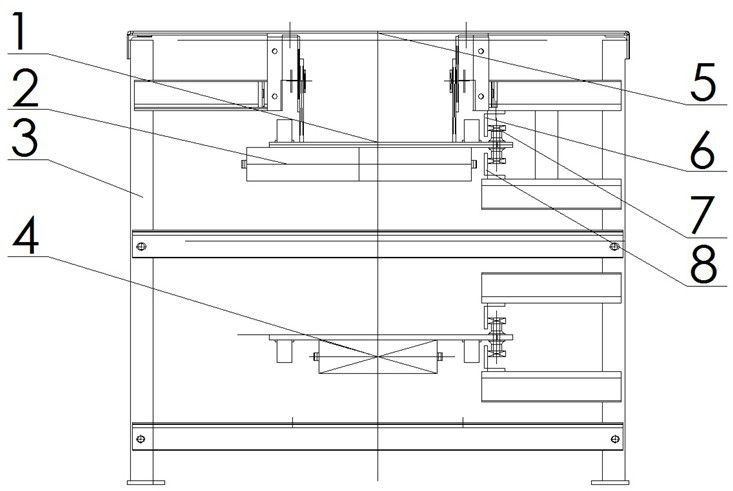

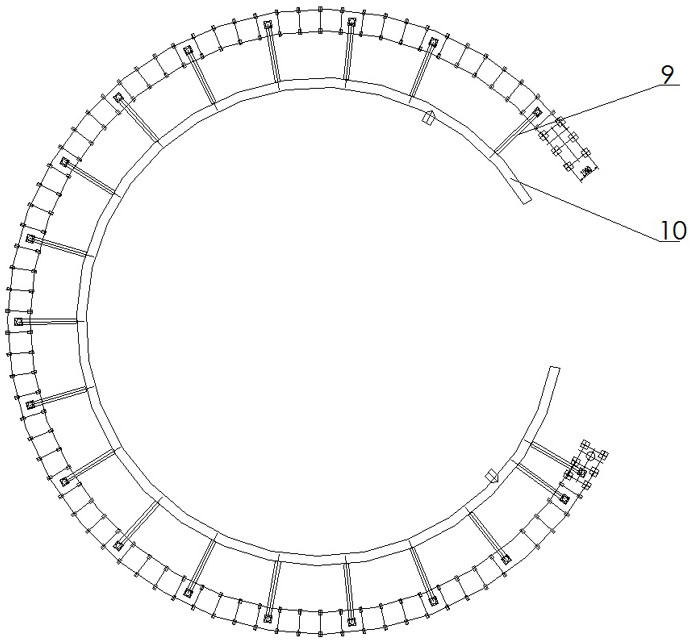

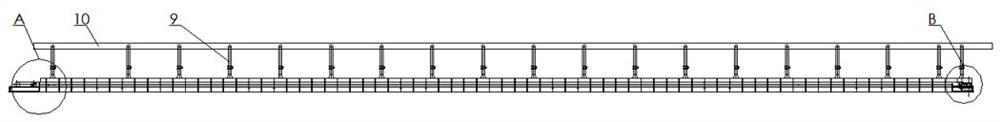

[0021] see Figure 1 to Figure 5 , a kind of endless ash conveyor, comprising a frame 3, the frame 3 is a double-layer ring structure with gaps, an endless conveyor belt 1 is installed on the frame 3, and two sets of drive motors 13 are connected to the endless conveyor belt 1, two The driving motor 13 makes the operation of the circular transmission more stable. The driven driving motor 13 is equipped with a tensioning wheel 12. The circular radius of the endless conveyor belt 1 is 10000-35000mm and the width is 400-1000mm. The part is installed on the upper layer of the frame 3, the return part of the endless conveyor belt 1 is installed on the lower layer of the frame 3, and the inner ring side and the outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com