Coring device for compression-resistant core sample of highway pavement

A core-taking device and core-sampling technology, applied in sampling devices and other directions, can solve problems such as affecting the service life of the overall equipment and inconvenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

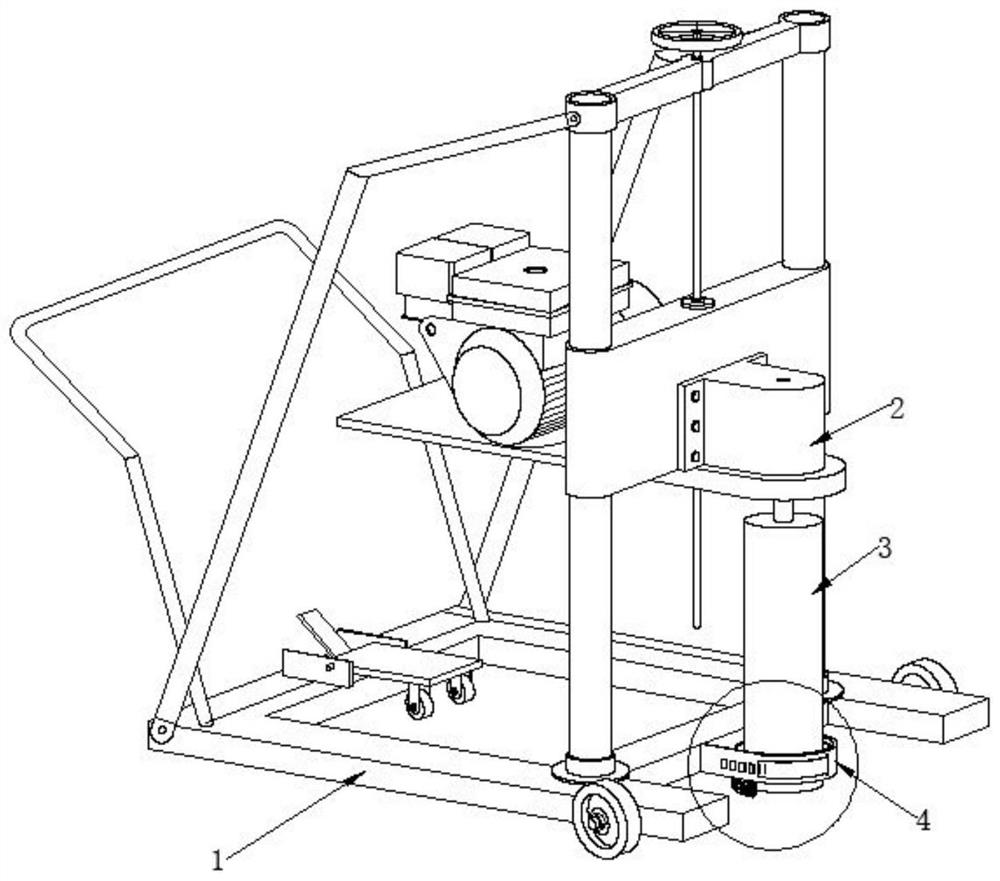

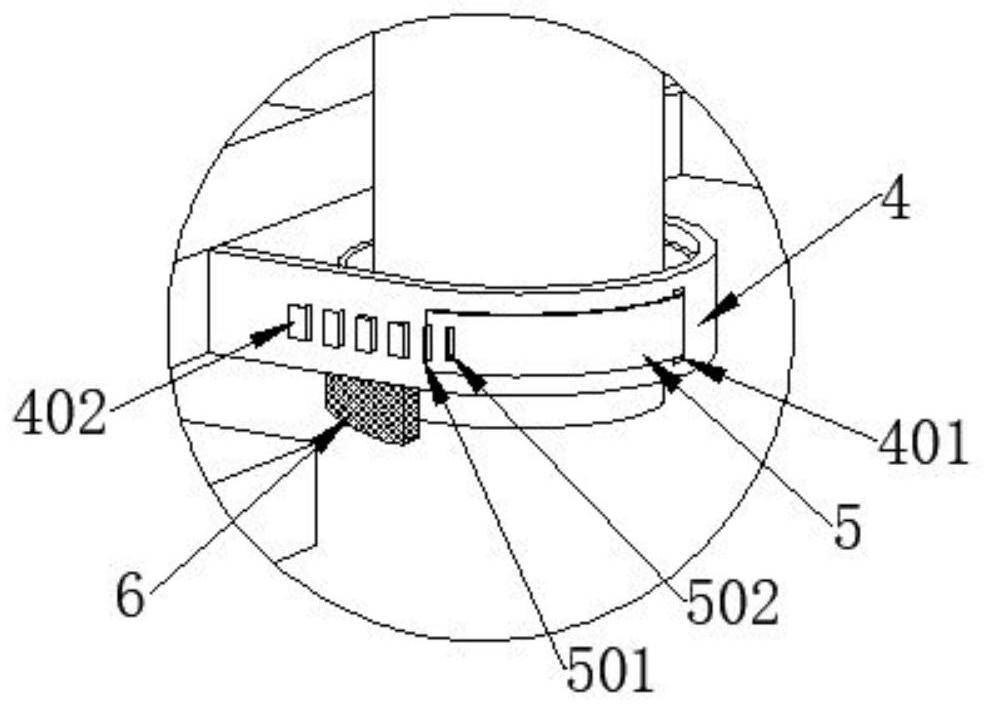

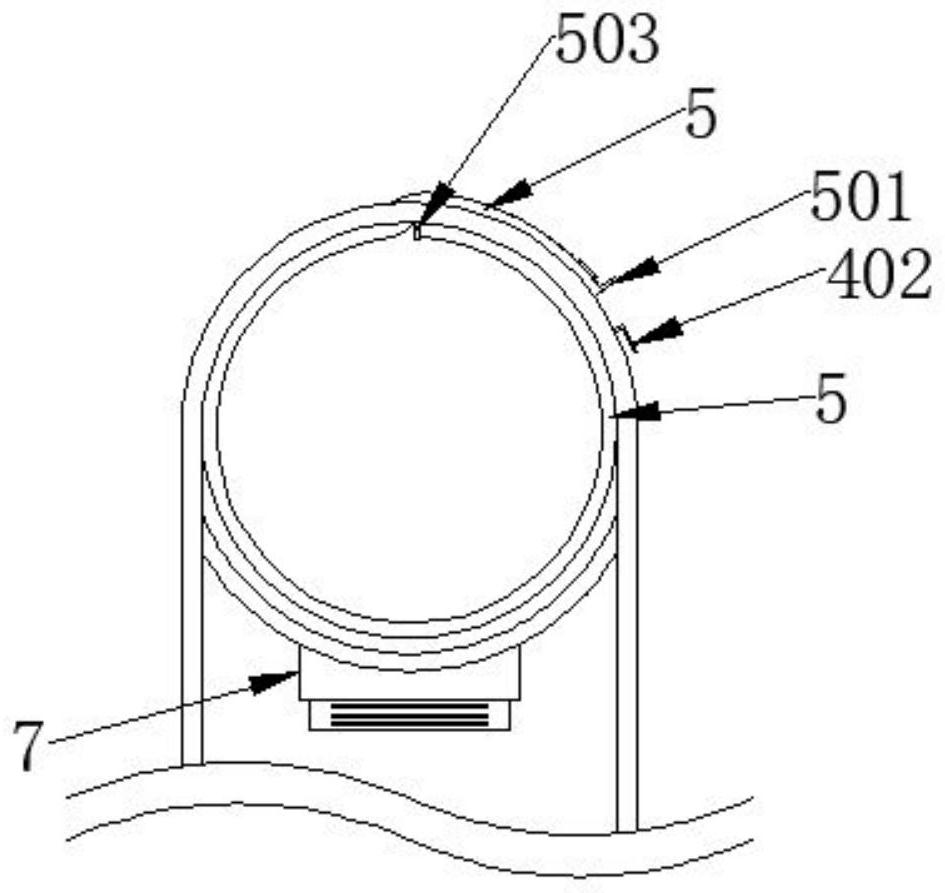

[0027] like Figure 1-6 As shown, the present invention provides a kind of anti-pressure core sample coring device for highway pavement, comprising core drilling machine main body 1, and core drilling machine main body 1 includes handrail, support, power engine, gearbox, positioning structure, supporting steel pipe, leveling Screws, water pump and transmission structure 2, the transmission structure 2 is set for the bearing seat assembly, the bottom end of the transmission structure 2 is installed with the coring cylinder 3, the bottom side of the core cylinder 3 is installed with the fixed ring 4, and the fixed ring 4 and the bracket For fixed connection, coil spring 5 is installed on the inner side of fixed ring 4, and handle 501 is installed on one end of its coil spring 5, and the inboard of handle 501 is provided with buckle groove 502, and the surface of fixed ring 4 is equipped with slot 401, slotted One side of 401 is equipped with a buckle block 402, the bottom end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com