Method for identifying propagation length of metal weld crack

A technology of weld crack and identification method, which is applied in the application of stable tension/pressure testing material strength, special data processing applications, measuring devices, etc. Fiber Bragg grating sensors and other problems, to achieve the effect of increasing monitoring sensitivity and high sensitivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 provides a kind of identification method of metal weld crack extension length, comprises the following steps:

[0043] Step A: Design of the metal weld crack growth model

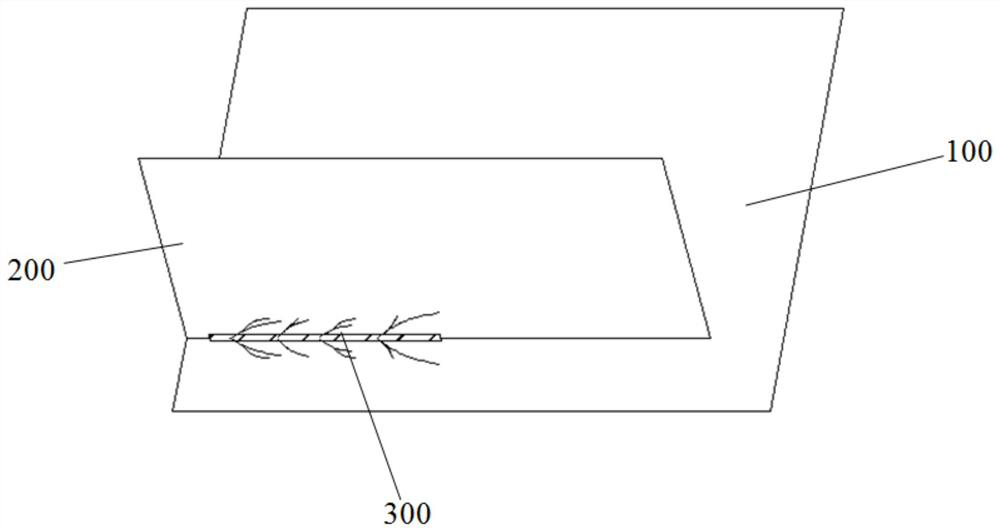

[0044] According to the stress and cracking of common welded structures in engineering, refer to figure 1 , place an upright steel plate 200 vertically on a horizontal bottom plate 100, and weld and fix the connection between the steel plate and the bottom plate to form a weld 300, and design a metal weld crack growth model accordingly;

[0045] Step B: using the existing finite element software abaqus to conduct finite element analysis on the metal weld crack growth model to obtain the strain amplitude distribution map;

[0046] Step B1: Size selection of the metal weld crack growth model and weld setting;

[0047] In the finite element analysis, the length, width and thickness of the steel plate 200 are 800×800×0.8 mm, the length, width and thickness of the bottom plate 100 are 1000×...

Embodiment 2

[0073] Example 2: An identification device for the extension length of a metal weld crack

[0074] Embodiment 2 provides an identification device for the extension length of a metal weld crack, including:

[0075] A first processing unit for designing a metal weld crack growth model;

[0076] The second processing unit is used to perform finite element analysis on the metal weld crack growth model by using finite element software to obtain a strain amplitude distribution map;

[0077] The third processing unit is used to calculate the sensing section and its packaging length according to the strain amplitude distribution diagram, and obtain the packaging length of all sensing sections;

[0078] The fourth processing unit is configured to construct a vector array according to the strain amplitude distribution map and the package lengths of all sensing sections, and establish a regression model of the crack growth length of the metal weld;

[0079] The fifth processing unit is...

Embodiment 3

[0080] Embodiment 3: a kind of computer-readable storage medium

[0081] Embodiment 3 provides a computer-readable storage medium on which a computer program is stored, and when the computer program is executed by a processor, the steps of the method in Embodiment 1 are implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com