Disc type motor rotor

A disc motor and rotor technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. The effect of preventing stress deformation, preventing dispersion of the magnetic conductive sheet, and improving the fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

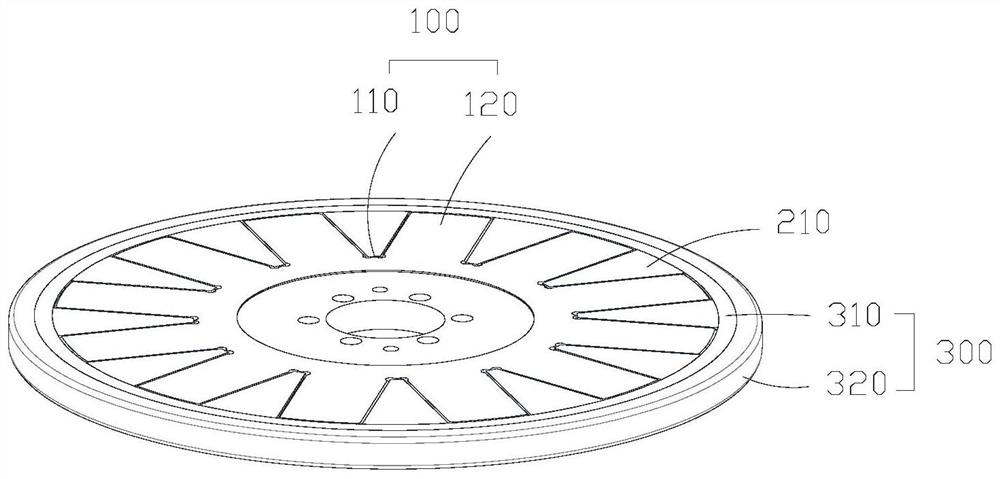

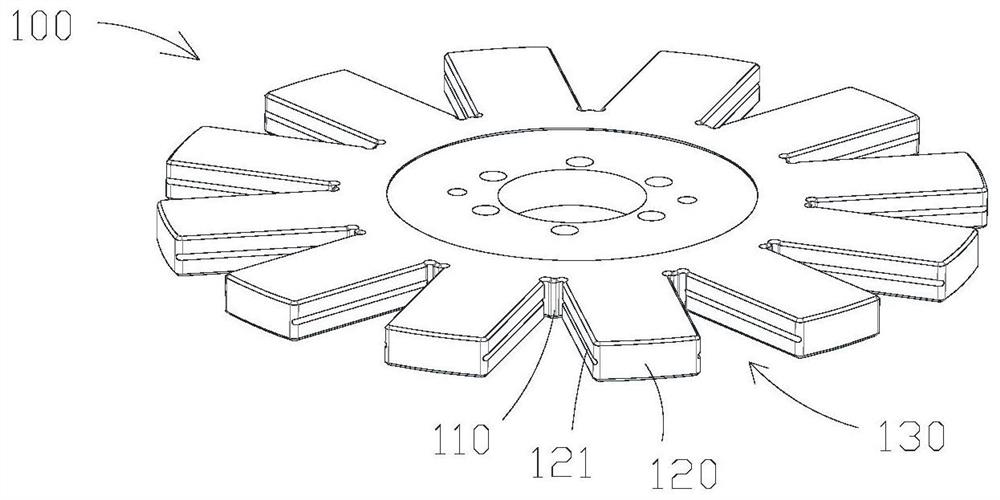

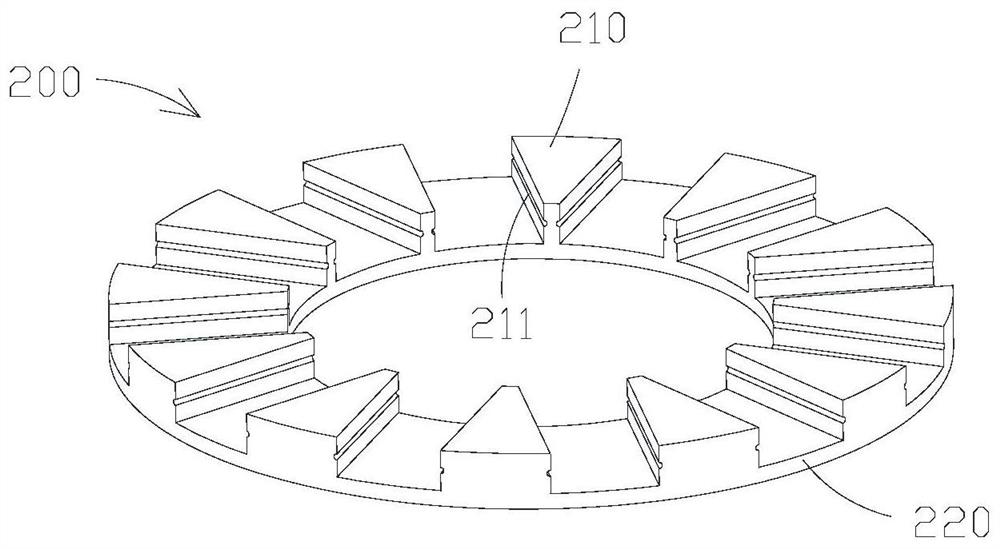

[0056] Such as Figure 1 to Figure 6 As shown, the disc motor rotor includes:

[0057] A non-magnetic cage 100, the non-magnetic cage 100 has a radial limiter 110 and a plurality of circumferential limiters 120, the plurality of circumferential limiters 120 are spaced apart and extend outward connected to the radial limiter 110;

[0058] A magnetically permeable assembly 200, the magnetically permeable assembly 200 has a plurality of magnetically perme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com