Multilayer positive and negative reverse rotation ceramic membrane

A counter-rotating, ceramic membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of time-consuming and laborious installation, complicated structural design of the rotating ceramic membrane system, and inconvenient system maintenance. Increase the processing quality, increase the filtering effect, increase the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

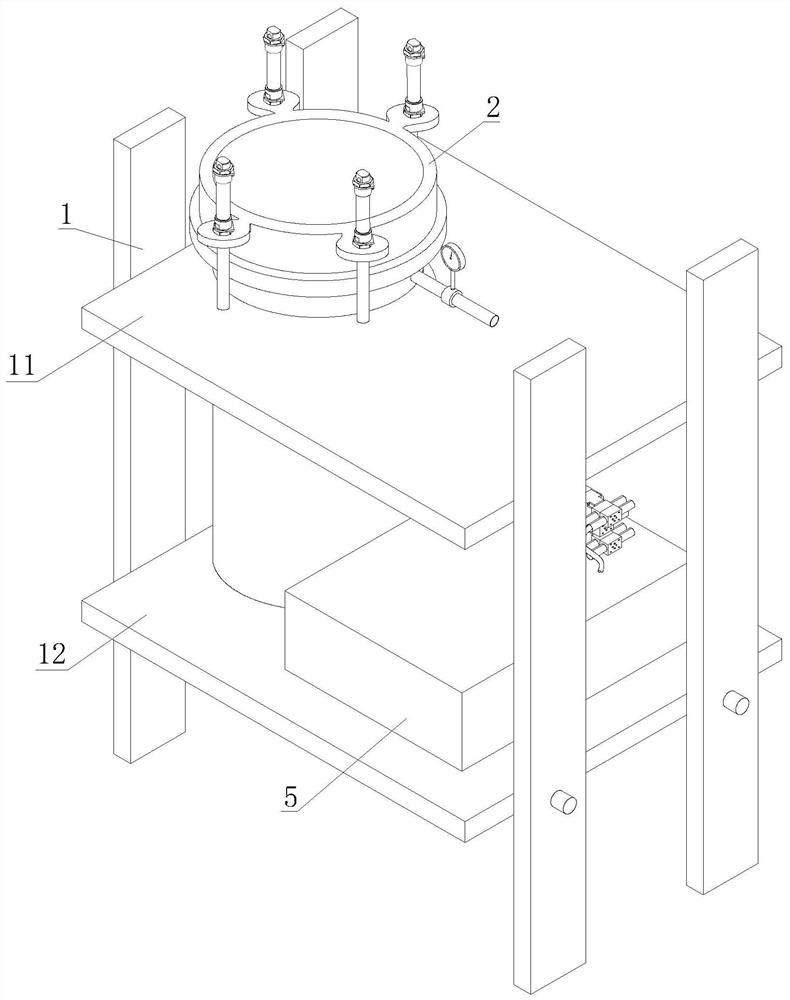

[0036] see figure 1, multi-layer forward and reverse rotating ceramic membranes, including a fixed bracket 1, an installation platen 11 is arranged above the fixed bracket 1, an installation notch 111 is opened on the installation platform 11, and a filter tank 2 is installed in the installation notch 111 to filter The interior of the tank 2 is provided with a ceramic filter membrane group 3, the ceramic filter membrane group 3 is sleeved on the power assembly 4, the upper end of the power assembly 4 penetrates the bottom end of the filter tank 2 and is sealed in the filter tank 2, and the lower part of the power assembly 4 is fixed On the load-bearing platform 12 under the fixed bracket 1, the bottom end of the filter tank 2 is set on the load-bearing platform 12, and the liquid inlet assembly 5 is arranged on the load-bearing platform 12 at the side end of the filter tank 2.

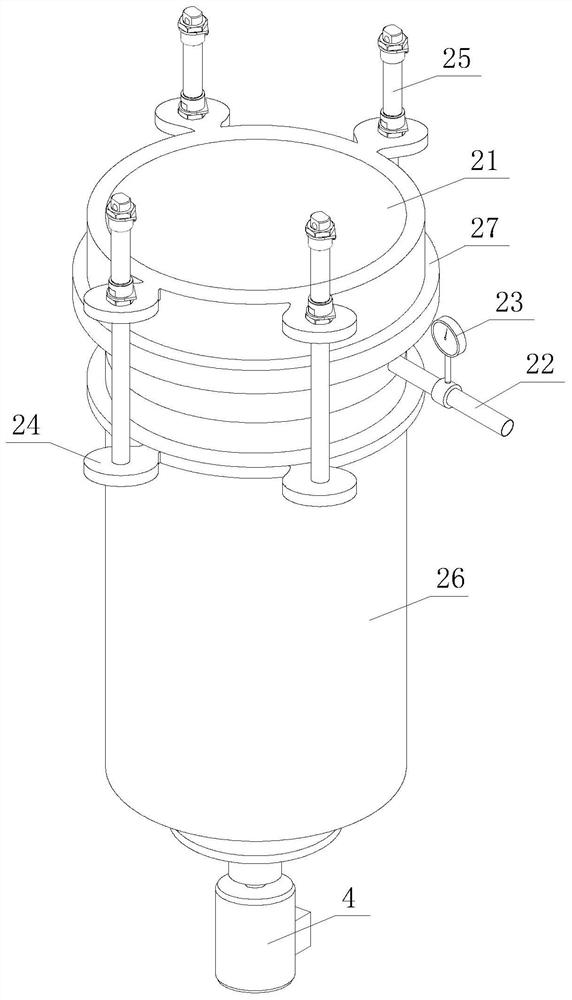

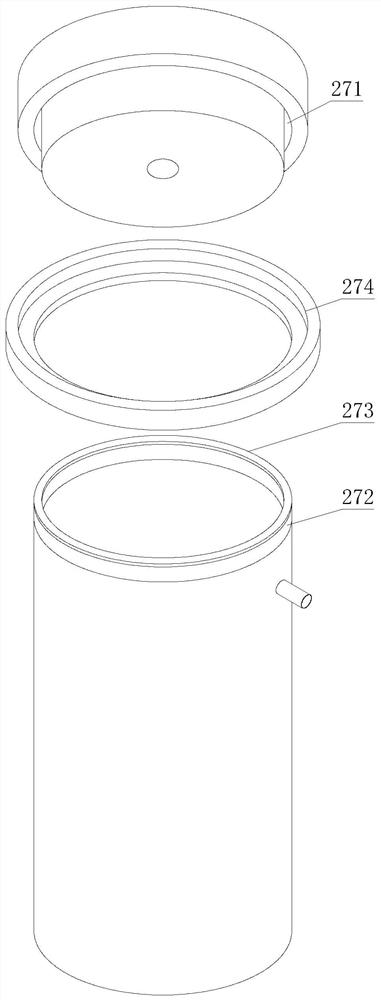

[0037] see Figure 2-Figure 3 , the filter tank 2 comprises an upper gland 21, an exhaust pipe 22,...

Embodiment 2

[0044] see Figure 11 , multi-layer forward and reverse rotating ceramic membranes, including a fixed bracket 1, an installation platen 11 is arranged above the fixed bracket 1, an installation notch 111 is opened on the installation platform 11, and a filter tank 2 is installed in the installation notch 111 to filter The interior of the tank 2 is provided with a ceramic filter membrane group 3, the ceramic filter membrane group 3 is sleeved on the power assembly 4, the upper end of the power assembly 4 penetrates the bottom end of the filter tank 2 and is sealed in the filter tank 2, and the lower part of the power assembly 4 is fixed On the load-bearing platform 12 below the fixed bracket 1, the bottom end of the filter tank 2 is arranged on the load-bearing platform 12, and the liquid inlet assembly 5 is arranged on the load-bearing platform 12 at the side end of the filter tank 2. The filter tank 2 includes an upper gland 21, a drain Trachea 22, pressure detector 23, docki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com