Disc drawing round pipe mold capable of being used by joint

A round tube and mold technology, which is applied in the field of coiled round tube molds, can solve the problems of reducing product output and cracking, and achieve the effect of increasing product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

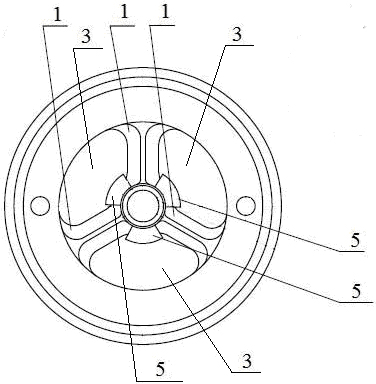

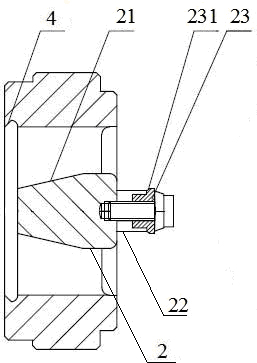

[0021] A coil-drawn round tube mold that can be used for joints, combined with Figure 1 to Figure 5 As shown, including matching upper mold and lower mold, the upper mold and the lower mold are provided with through holes, and the discharge end surface of the upper mold and the feed end surface of the lower mold are tightly connected by the pin shaft pierced in the through hole. Fixed connection.

[0022] The feeding die mouth of the upper mold is processed with an undercut 4, which can prevent gaps caused by turning over aluminum on the die mouth plane of the upper mold after the mold squeezes out a section of aluminum rod, and the mold mouth is made into a circle of undercut 4, so that After extruding a section of aluminum rod, the shearing plane is flat and there is no gap. The inside of the upper die is provided with three spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com