Thin plate flattening device

A thin plate and extruded plate technology, applied in the field of leveling, to achieve the effects of guaranteed leveling quality, convenient movement, time-saving, labor-saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

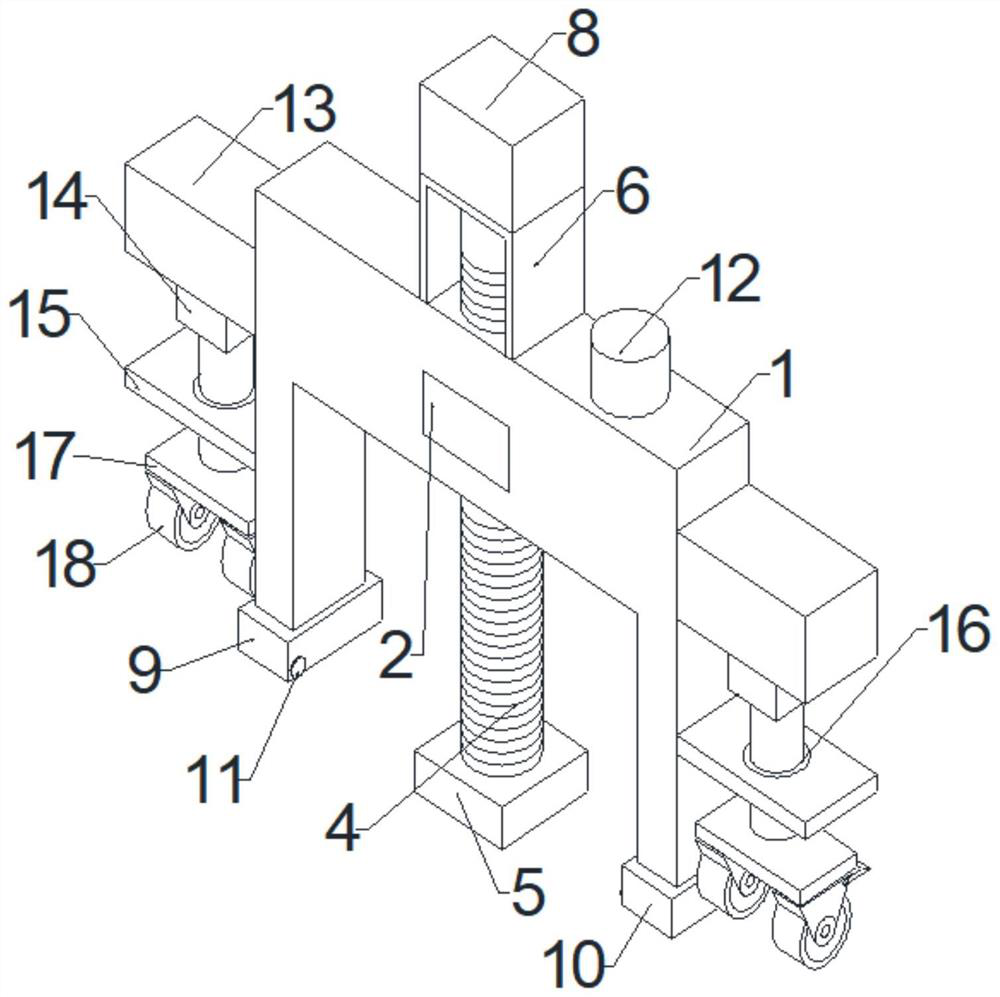

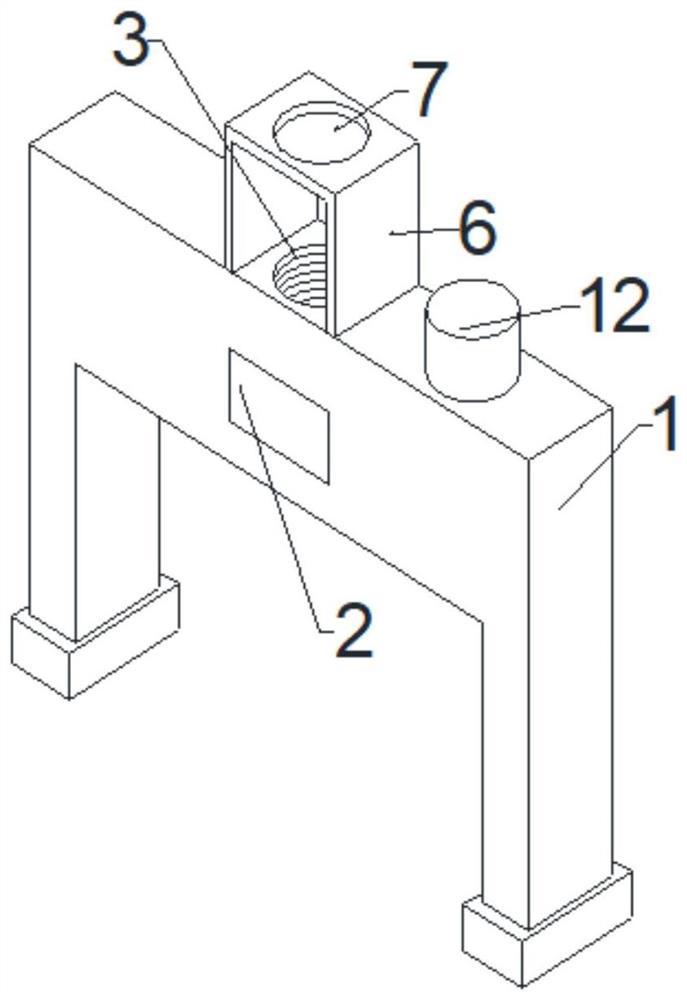

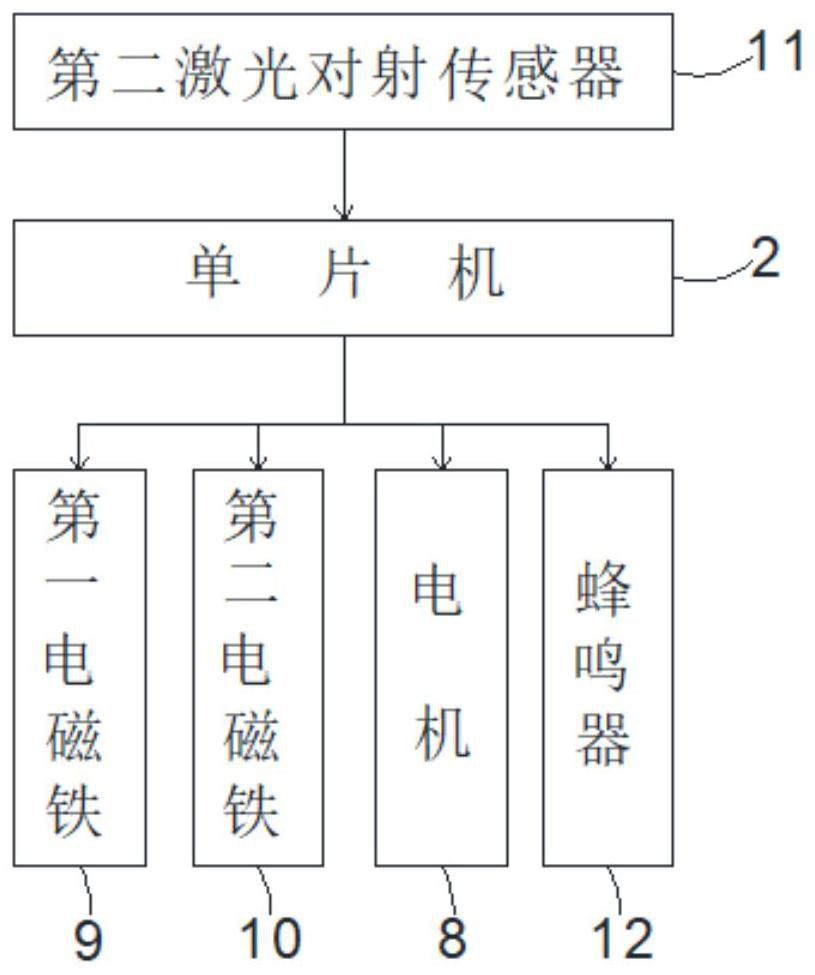

[0030] Such as Figure 1-3 A thin plate leveling device shown includes:

[0031] I-shaped support 1; specifically, the middle part of the I-shaped support 1 is provided with a threaded hole 3 vertically downward; the buzzer 12 is fixed on the described I-shaped support 1; preferred in this embodiment, the The model of the buzzer 12 is KLJ-9032, and when the equipment completes its work, the user will be reminded by the buzzer 12 to increase the use efficiency of the equipment;

[0032] The extruding assembly arranged on the I-shaped support 1; specifically, the extruding assembly includes: threaded rod 4, extruding plate 5, motor fixing seat 6 and motor 8; the extruding plate 5 is fixed on The bottom of the threaded rod 4, the threaded rod 4 is threaded in the threaded hole 3; the motor holder 6 is fixed on the I-shaped support 1, and the motor holder 6 is vertically provided with The first through hole 7; the motor 8 is fixed on the motor holder 6, and the output shaft of t...

Embodiment 2

[0036] refer to Figure 4-6 , further comprising: moving components arranged on the left and right sides of the I-shaped support 1 respectively.

[0037] Specifically, the moving assembly includes: a first fixed part 13, a telescopic cylinder 14, a second fixed part 15, a third fixed part 17 and two roller assemblies 18; the first fixed part 13 and the second fixed part Parts 15 are respectively fixed on the side walls of the I-shaped bracket 1, the second fixing part 15 is directly below the first fixing part 13, and a second fixing part 15 is vertically opened on the second fixing part 15. A through hole 16, the second through hole 16 is provided with a rubber ring 21; the telescopic cylinder 14 is fixed on the bottom of the first fixture 13, and the telescopic end of the telescopic cylinder 14 passes through the rubber ring 21 and Fixed with the third fixture 17; the bottom of the third fixture 17 is fixed with two roller assemblies 18; when the telescopic cylinder 14 work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com