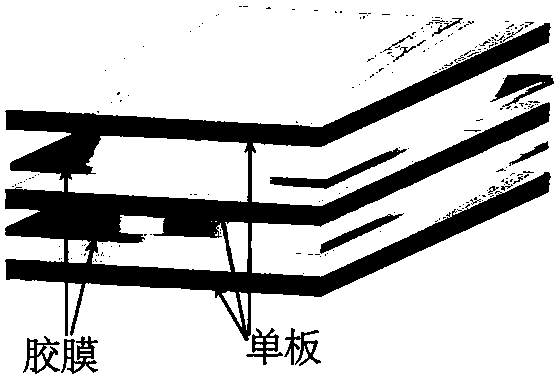

Starch-PVA (Polyvinyl Alcohol)-chitosan blended film and method for preparing plywood through hot-pressing

A chitosan and blended film technology, applied in starch adhesives, chitin adhesives, film/sheet-like adhesives, etc., can solve the problem of non-biodegradation, softening and deformation of the adhesive layer, and decreased bonding strength and other problems, to achieve the effect of simple method, good compatibility and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh the starch and put it in the reaction kettle, add water of equal quality, stir continuously and raise the temperature to 40°C, adjust the pH=11, add sodium hypochlorite solution (available chlorine 10%), stir for 3.5h, then add sodium sulfite, stir 10min, then add a PVA solution with a concentration of 10% and stir for 20min, then add a chitosan solution with a concentration of 5% and stir for 1h, heat up to 75°C and gelatinize into a gel to obtain a starch-PVA-chitosan adhesive; wherein, The amount of sodium hypochlorite solution (10% available chlorine) added is 8% of the dry weight of the starch, the amount of sodium sulfite added is 2% of the sodium hypochlorite solution (10% available chlorine), and the amount of PVA (dry weight) added is 20% of the dry weight of the starch. The amount of chitosan (dry weight) added is 50% of the dry weight of starch;

[0040] (2) Degas the obtained starch-PVA-chitosan adhesive under the condition of vacuum degree of 0.1 ...

Embodiment 2

[0044] (1) Weigh the starch and put it in the reaction kettle, add water of equal quality, stir continuously and raise the temperature to 50°C, adjust the pH=10, add potassium permanganate, stir for 45min, then add sodium sulfide, stir for 10min, then add Stir the PVA solution with a concentration of 10% for 30 minutes, then add a chitosan solution with a concentration of 5% and stir for 0.5 hours, heat up to 68°C and gelatinize to form a starch-PVA-chitosan adhesive; among them, permanganate The addition of potassium is 3% of the dry weight of starch, the addition of sodium sulfide is 5% of the dry weight of potassium permanganate, the addition of PVA (dry weight) is 5% of the dry weight of starch, and the addition of chitosan (dry weight) The amount is 30% of the dry weight of starch;

[0045] (2) The obtained starch-PVA-chitosan adhesive was degassed under the condition of vacuum degree of 0.9MPa, scraped on a chrome-plated steel plate to form a film, and dried at a constan...

Embodiment 3

[0049] (1) Weigh the starch and put it in the reaction kettle, add equal quality water, stir continuously and raise the temperature to 60°C, adjust the pH=9, add 30wt% hydrogen peroxide solution, stir for 1h, then add sodium sulfite, stir for 10min, then Add a PVA solution with a concentration of 10% and stir for 25 minutes, then add a chitosan solution with a concentration of 5% and stir for 0.5 hours, heat up to 70°C and gelatinize to obtain a starch-PVA-chitosan adhesive; The amount of hydrogen solution added is 5% of the dry weight of starch, the amount of sodium sulfite added is 10% of the weight of hydrogen peroxide solution; the amount of PVA (dry weight) added is 10% of the dry weight of starch; the amount of chitosan (dry weight) added is 40% of the dry weight of starch;

[0050] (2) Degas the obtained starch-PVA-chitosan adhesive under the condition of vacuum degree of 0.95 MPa, scrape a film on a chrome-plated steel plate, dry at a constant temperature of 40°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bonding strength | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com